A method for preventing explosion of high-draw carbon converter dry dust removal system

A technology of converter dry dust removal and high carbon pulling, which is used in the manufacture of converters and other directions, can solve problems such as electrostatic precipitator explosion venting, and achieve the effects of safe production, prevention of explosion venting, and improvement of molten steel quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

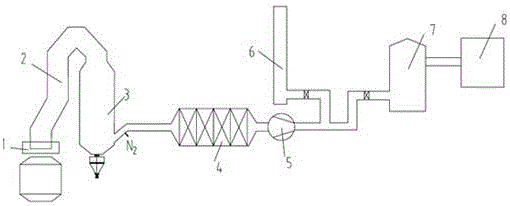

Method used

Image

Examples

Embodiment 1

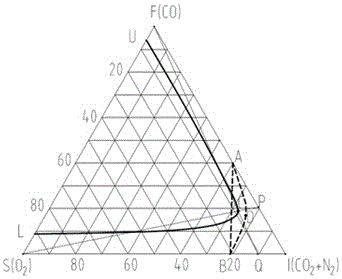

[0042] In this embodiment, furnace number 4A10149, steel number: HRB400B, steel type: low alloy, C: 0.20-0.25%. When the low alloy is produced by the high carbon drawing method, the oxygen flow is manually adjusted to 50% of the rated oxygen supply flow 20s before carbon drawing, and the nitrogen valve behind the evaporative cooler is opened at the same time, the nitrogen flow rate is 7800Nm3 / h, and the nitrogen filling time is 30s . Oxygen flow rate is by rated oxygen supply flow rate when supplementary blowing, does not operate according to the method of the present invention. Draw CO-O2-CO2(+N2) according to the flue gas composition of the furnace number Figure 5 Ternary graph, by Figure 5 It can be seen that the smoke components did not bypass the explosion hazard zone during supplementary blowing. The field practice showed that during the smelting of this furnace number, a small explosion vent occurred during supplementary blowing.

Embodiment 2

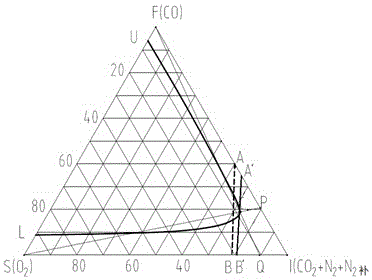

[0044] In this embodiment, furnace number 4B12161, steel number: 55#, steel type: high carbon steel, C: 0.53-0.57%. Use the high carbon method to control the end point, manually adjust the oxygen flow to 50% of the rated oxygen supply flow 20s before pulling carbon, and open the nitrogen valve behind the evaporative cooler at the same time, the nitrogen flow rate is 7800Nm 3 / h, nitrogen flushing time 30s. During supplementary blowing, the oxygen flow is manually adjusted so that the oxygen supply flow is 65% of the rated oxygen flow. According to the flue gas composition of the furnace number, the CO-O 2 -CO 2 (+N 2 ) Figure 6 Ternary diagram, the dotted line ABC is flue gas CO-O when high carbon is drawn 2 -CO 2 (+N 2 ) composition curve, it can be seen from the figure that the composition obviously avoids the explosion area. CD is CO-O when supplementary blowing 2 -CO 2 (+N 2 ) composition curve, and the composition is also far away from the explosion range. No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com