Two-way deposition coating device and coating method

A technology of a coating device and a coating cavity, which is applied in the field of bidirectional deposition coating devices, can solve the problems such as the failure rate of the flipping mechanism cannot be ignored, increase the design and manufacturing cost, affect the product yield rate, etc., and achieve the improvement of coating efficiency and quality. The effect of reducing the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

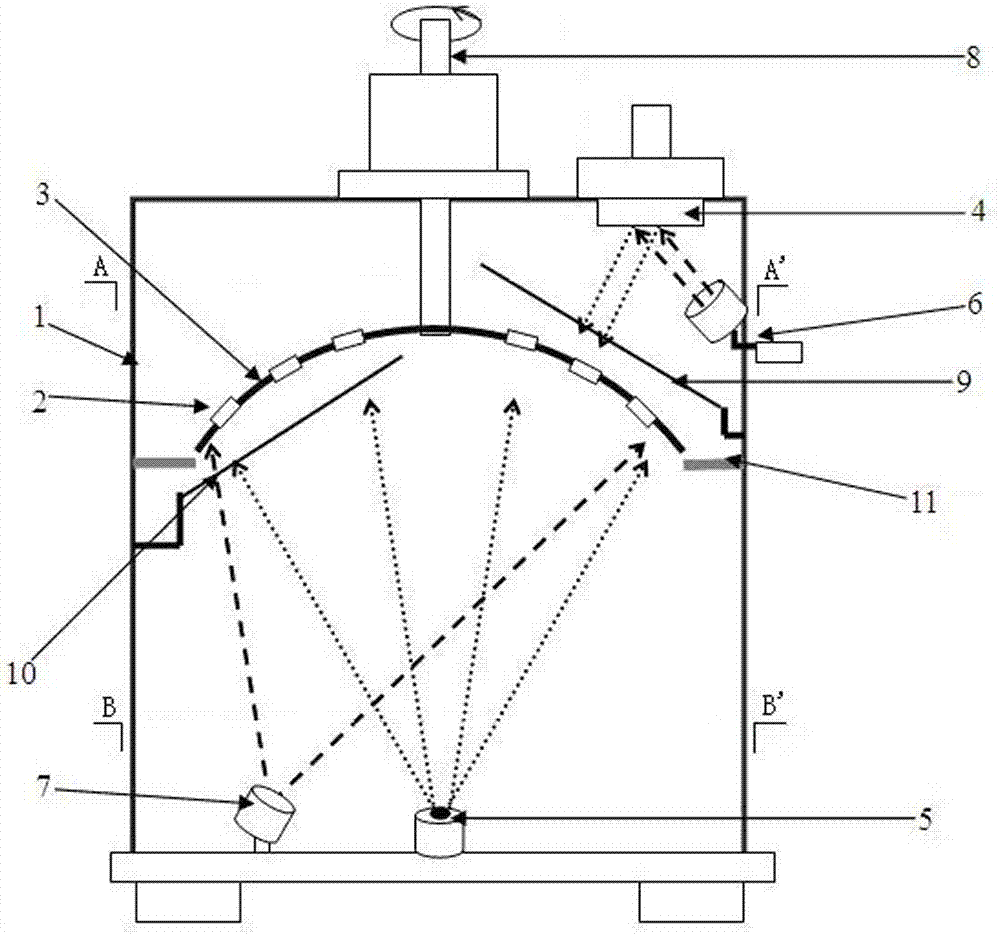

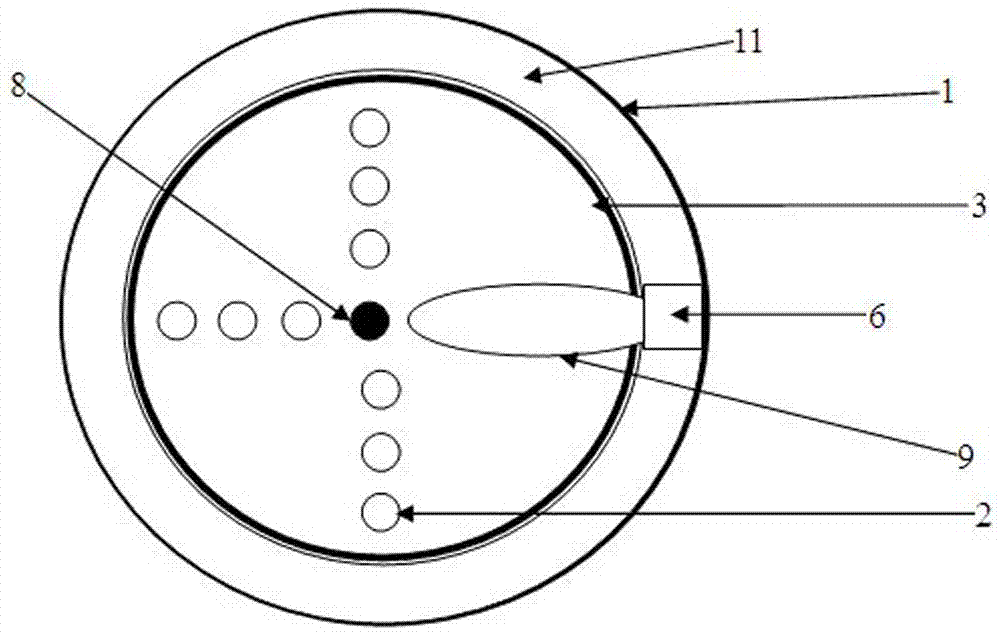

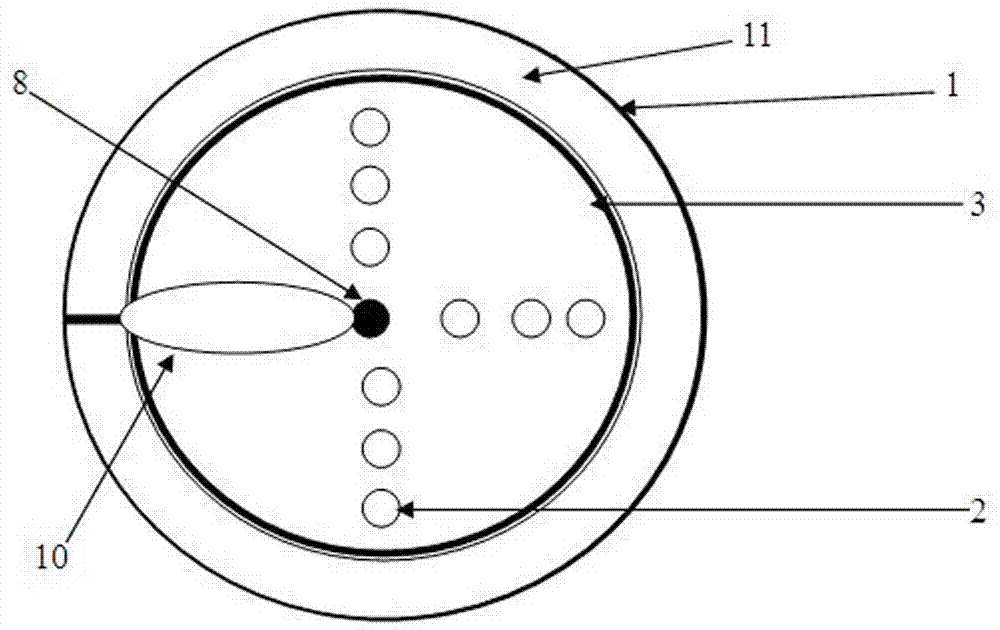

[0019] Example: such as figure 1 As shown, the bidirectional deposition and coating device in this embodiment includes a coating chamber 1 . A workpiece umbrella frame 3 for carrying a substrate 2 is arranged inside the coating chamber 1 . The central position of the workpiece umbrella stand 3 is provided with a rotating mechanism 8, and the rotating mechanism 8 rotates through an external driving device, and the workpiece umbrella stand 3 can rotate at a uniform speed with the rotating mechanism 8. The below of workpiece umbrella frame 3 is provided with evaporation source 5 and ion source 7, and wherein ion source 7 is used for assisting evaporation source 5 to make evaporation film material be deposited on one side surface of substrate 2 (in figure 1 Indicated as the lower surface of the substrate 2).

[0020] The top of the workpiece umbrella frame 3 is provided with a sputtering target 4 and a radio frequency source 6, the sputtering target 4 is arranged on the top of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap