Construction method of outer wrapped concrete steel pipe composite column

A technology of outsourcing concrete and construction methods, which is applied in the processing of building materials, arched beams, bridge door beams, etc., can solve the problems of inconvenient construction of the outer layer structure of steel pipe columns, difficult chiseling of concrete laitance, and long heat preservation time. Achieve the effect of avoiding concrete segregation, shortening construction period, and avoiding thermal insulation treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

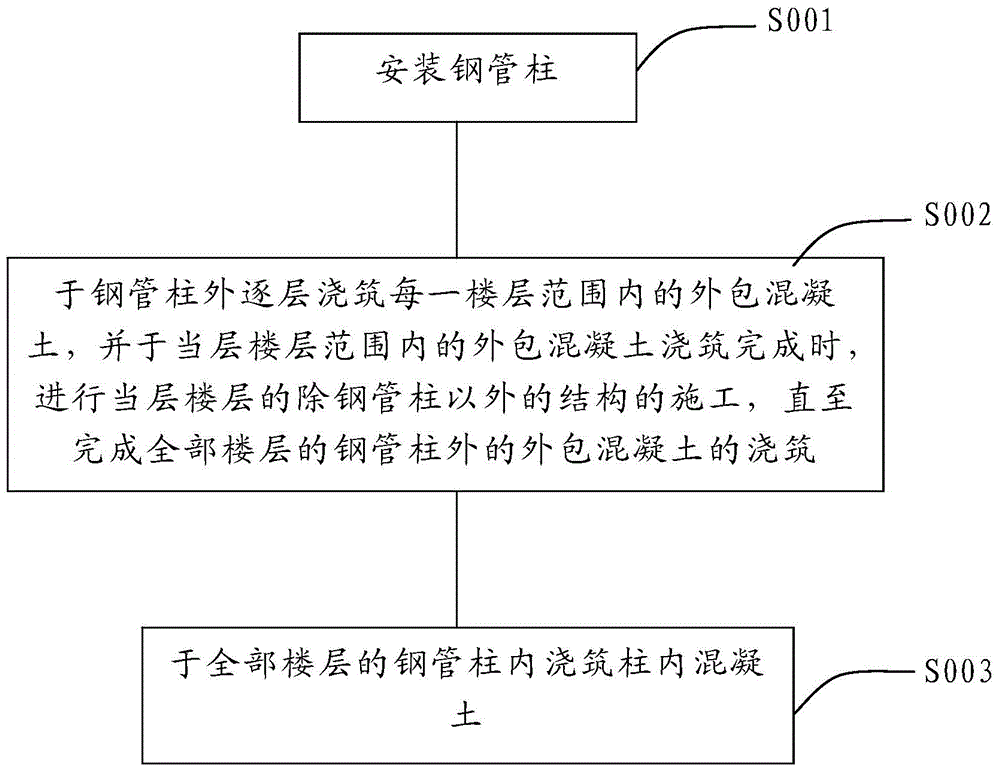

[0032] The construction method of a kind of outsourcing concrete steel pipe composite column of the present invention mainly comprises the following construction steps:

[0033] S001: Install steel pipe column;

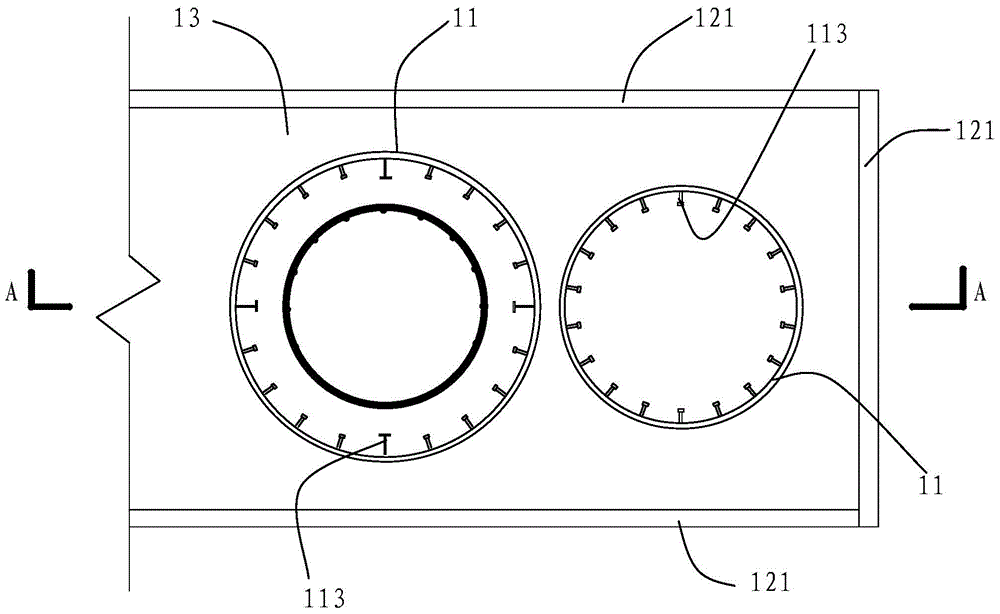

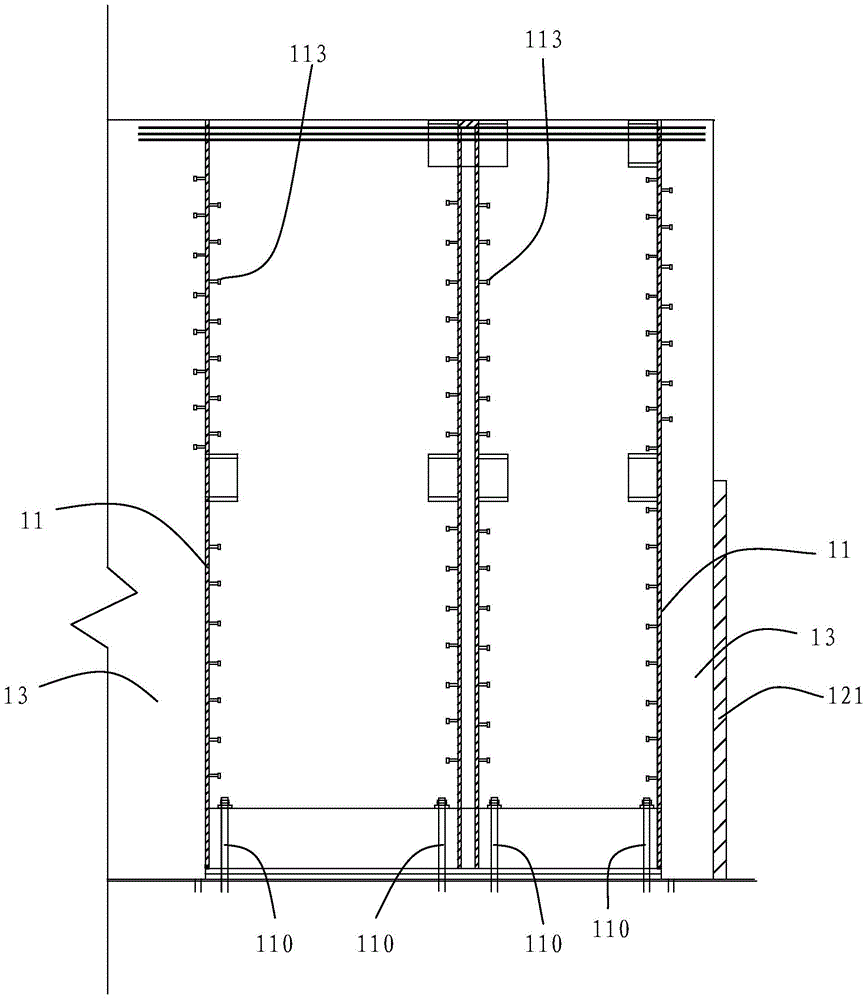

[0034] refer to Figure 1~3 As shown, in this embodiment, the steel pipe column 11 is a two-section column with a floor height of a two-story building, and the height of each section is the height of one floor.

[0035] Firstly, the bottom of the steel pipe column 11 is fixed with column foot bolts 110 to prevent the steel pipe column 11 from shifting during concrete pouring;

[0036] Then, pre-install the steel bar structure 113 of all floors (two floors) in the steel pipe column 11. The steel bar structure 113 in the column is composed of vertical bars, hoops, etc., and is supported on the column wall of the steel pipe co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com