Nickel-free white copper alloy strip foil and preparation method thereof

A copper alloy strip, white technology, applied in the field of metal material processing, can solve problems such as difficult industrialized production, and achieve the effects of high yield, avoiding heat treatment process, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

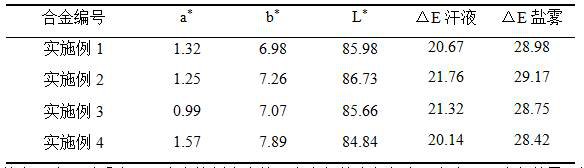

Examples

Embodiment 1

[0028] (1) The composition of the foil blank is (mass percentage): Zn: 14%, Mn: 10%, Al: 1.0%, Sn: 1.0%, Ti: 0.15%, Si: 0.1%, B: 0.3%, Ce: 0.08%, the balance is an alloy of Cu and unavoidable impurities;

[0029] (2) Melting

[0030] According to the designed white copper alloy composition ratio, pure zinc, pure manganese, pure aluminum, pure tin, copper-titanium master alloy, copper-silicon master alloy, copper-boron master alloy, copper-cerium master alloy and electrolytic copper Melt in an intermediate frequency induction furnace, remove slag, and cover with charcoal. When the temperature rises to 1240°C, take a sample from the furnace. Cover with charcoal and let stand for 30 minutes;

[0031] (3) Horizontal continuous casting

[0032]After confirming that the complete equipment of the horizontal continuous casting machine is in normal operation and the dummy device can rotate flexibly, start casting and drawing the billet. During the drawing process, it is required to ...

Embodiment 2

[0042] (1) The composition of the foil blank is (mass percentage): Zn: 11%, Mn: 14%, Al: 1.0%, Sn: 0.9%, Ti: 0.06%, Si: 0.3%, B: 0.02%, Ce: 0.3%, the balance is an alloy of Cu and unavoidable impurities;

[0043] (2) Melting

[0044] According to the designed white copper alloy composition ratio, pure zinc, pure manganese, pure aluminum, pure tin, copper-titanium master alloy, copper-silicon master alloy, copper-boron master alloy, copper-cerium master alloy and electrolytic copper Melt in the intermediate frequency induction furnace, add charcoal covering after slag removal, when the temperature rises to 1210 ° C, take the sample in the furnace, after the spectral analysis components meet the requirements, let the converter stand still, remove slag again and add charcoal covering, fully stand for 40 minutes;

[0045] (3) Horizontal continuous casting

[0046] After confirming that the complete set of equipment of the horizontal continuous casting machine is in normal operat...

Embodiment 3

[0056] (1) Foil blank composition (mass percentage): Zn: 12%, Mn: 12%, Al: 0.9%, Sn: 1.1%, Ti: 0.1%, Si: 0.2%, B: 0.05%, Ce: 0.1 %, the balance is an alloy of Cu and unavoidable impurities;

[0057] (2) Melting

[0058] According to the designed white copper alloy composition ratio, pure zinc, pure manganese, pure aluminum, pure tin, copper-titanium master alloy, copper-silicon master alloy, copper-boron master alloy, copper-cerium master alloy and electrolytic copper Melt in the intermediate frequency induction furnace, remove slag and cover with charcoal. When the temperature rises to 1230 ° C, take the sample in the furnace. After the spectral analysis components meet the requirements, leave the converter at rest, remove slag again and cover with charcoal, and let it stand for 25 minutes;

[0059] (3) Horizontal continuous casting

[0060] After confirming that the complete equipment of the horizontal continuous casting machine is in normal operation and the dummy device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com