Preparation method for fuel cell gas diffusion layer with hydrophobicity

A gas diffusion layer and fuel cell technology, applied to electrical components, battery electrodes, circuits, etc., can solve the problems of high processing temperature, long processing time, and high production cost in the production process, and achieve simple process processing and avoid high-temperature processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

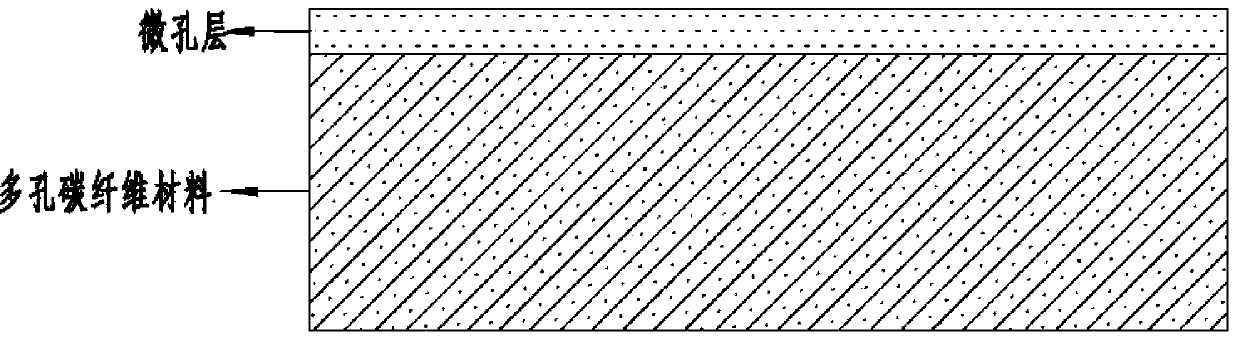

Image

Examples

Embodiment 1

[0024] (1) Completely immerse the carbon fiber material (TGP~H~060 from Toray, with a thickness of 190 μm and a porosity of 78%) in furfuryl alcohol solvent;

[0025] (2) The carbon fiber material is taken out of the furfuryl alcohol solvent and dried at a temperature of 80°C for about 5 minutes;

[0026] (3) Weigh 5g of carbon powder (Cabot Vulcan XC~72R, the particle size is about 30nm, and the specific surface area is about 250m 2 / g), 30g furfuryl alcohol, 30g water and ultrasonically mixed for 30 minutes to obtain microporous layer slurry;

[0027] (4) The microporous layer slurry is coated on one side of the hydrophobically treated carbon fiber material, and dried at a temperature of 80°C for about 5 minutes to obtain a gas diffusion layer.

Embodiment 2

[0029] (1) Completely immerse the carbon fiber material (TGP~H~090 of Toray Company, thickness 280 μm, porosity 78%) in a mixed solvent of furfural and bisfurfuryl alcohol (mass ratio 1:1);

[0030] (2) The carbon fiber material is taken out from the mixed solvent of furfural and difurfuryl alcohol, and dried at a temperature of 150°C for about 5 minutes;

[0031] (3) Weigh 5g of carbon powder (Ketjenblack EC-300J from Kejen Carbon Black Company, the particle size is about 50nm, and the specific surface area is about 250m 2 / g), 30g of a mixed solvent of furfural and difurfuryl alcohol (mass ratio 1:1), 30g of water and ultrasonic for 30 minutes to prepare the microporous layer slurry;

[0032] (4) The microporous layer slurry is coated on one side of the hydrophobically treated carbon fiber material, and dried at a temperature of 60°C for about 30 minutes to obtain a gas diffusion layer.

Embodiment 3

[0034] (1) Completely impregnate the carbon fiber material (GDS310 from Carbon Energy Company, with a thickness of 310 μm and a porosity of 77%) in a mixed solvent of furfuryl alcohol, furfural, and difurfuryl alcohol (mass ratio 1:1:1);

[0035] (2) The carbon fiber material is taken out from the mixed solvent of furfural and difurfuryl alcohol, and dried at a temperature of 150°C for about 5 minutes;

[0036] (3) Weigh 5g carbon powder (Cabot FCX80, the particle size is about 100nm, the specific surface area is about 800m 2 / g), 30g of furfuryl alcohol, furfural and bisfurfuryl alcohol were mixed and dissolved (mass ratio 1:1:1), 30g of water was ultrasonically mixed for 30 minutes to prepare the microporous layer slurry;

[0037] (4) The microporous layer slurry is coated on one side of the hydrophobically treated carbon fiber material, and dried at a temperature of 150°C for about 5 minutes to obtain a gas diffusion layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com