Experimental method of simulating cementing in well cementation process

An experimental method, cementing technology, applied in earthwork drilling, flushing wellbore, wellbore/well components, etc., can solve problems such as complex, inapplicable cementing system explanation, and difficult for students to understand the process, so as to stimulate enthusiasm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The experimental method of cementing in a kind of simulated cementing process that the present invention mentions comprises the following steps:

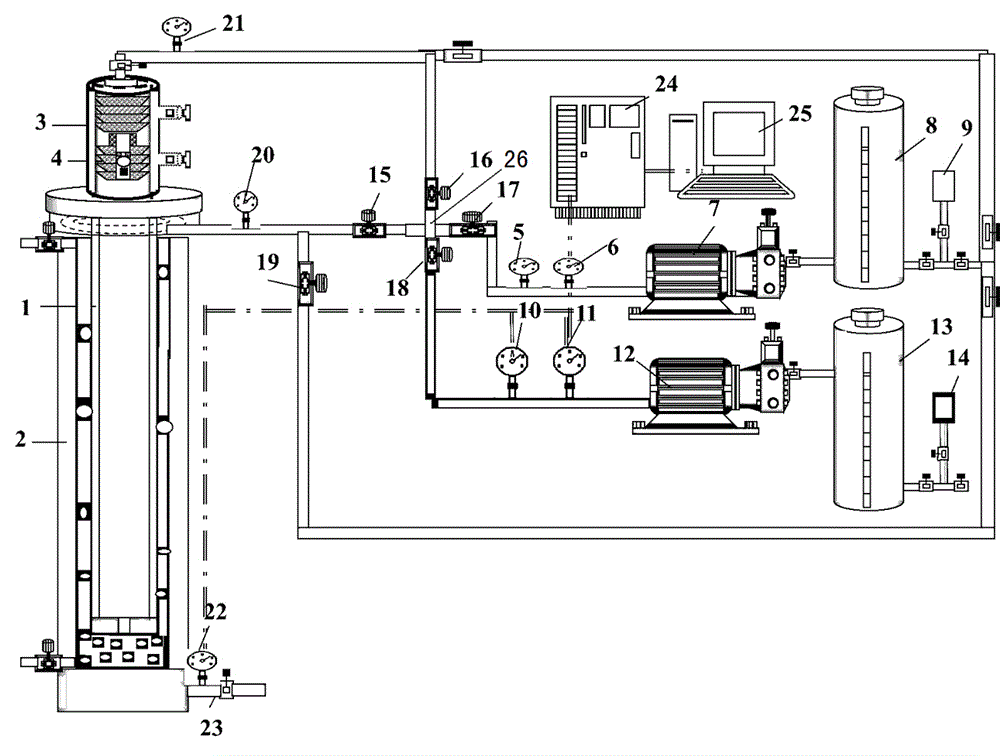

[0019] First, assemble the experimental equipment, which includes a wellbore simulation system, a drilling fluid circulation system, a cementing system, and a computer data processing system, wherein the wellbore simulation system includes a plexiglass inner tube 1 for simulating a drill string, and plexiglass for simulating a casing. Outer pipe 2, inner rotating motor 3, check valve 4, organic glass outer pipe 2 is arranged on the outside of organic glass inner pipe 1, inner rotating motor 3 and Check valve 4; drilling fluid circulation system includes drilling fluid circulation pipeline pressure gauge 5, drilling fluid flow meter 6, drilling fluid metering pump 7, drilling fluid storage tank 8; cement injection system includes cement flow pipeline pressure gauge 10, cement Flow meter 11, cement metering pump 12, cement stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com