Plate waveform scanning device for plate heat exchanger

A technology of plate heat exchangers and scanning devices, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the heat exchange area cannot be accurately measured, the data can only be recorded manually, and the quality inspection methods are backward, so as to achieve convenient testing Fast, high detection efficiency, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

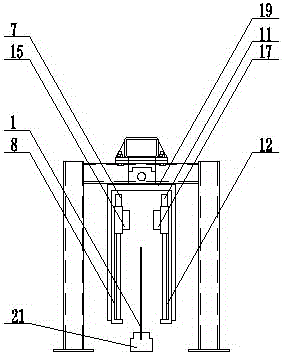

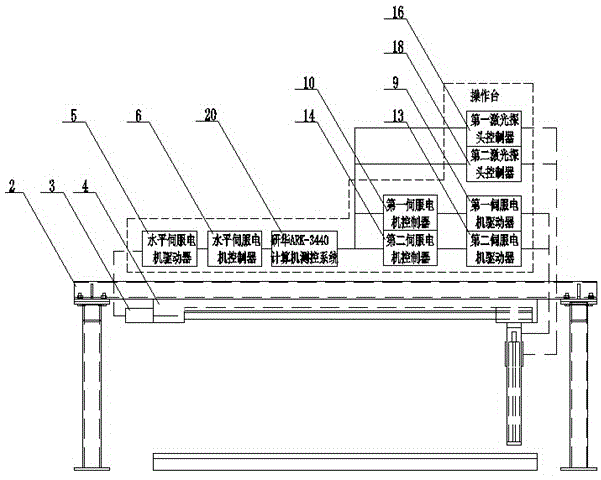

[0012] Such as figure 1 , figure 2 As shown, a plate heat exchanger plate waveform scanning device is composed of a measuring gantry support, a plate fixing mechanism, a ball screw linear travel mechanism, a two-axis servo synchronization system, a laser scanning sensor, and Advantech ARK-3440 computer measurement and control system. ;The laser scanning sensor is installed on the slider of the ball screw linear travel mechanism, so that the two laser scanning sensors on both sides of the plate are controlled by the servo system to move synchronously, and the positive and negative sides of any position of the plate can be measured. Waveform and plate thickness and other parameters. The specific structure is: the horizontal linear guide rail 4 is installed under the beam of the gantry support 2, the U-shaped bracket 19 is installed upside dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com