Engine air cylinder sealing performance test method and system

A technology of engine cylinder and test system, which is applied in the direction of engine test, fluid tightness test, machine/structural component test, etc. It can solve the problems of engine component damage, long test process, and component complexity, and improve test efficiency. , improve accuracy, and test rapid results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

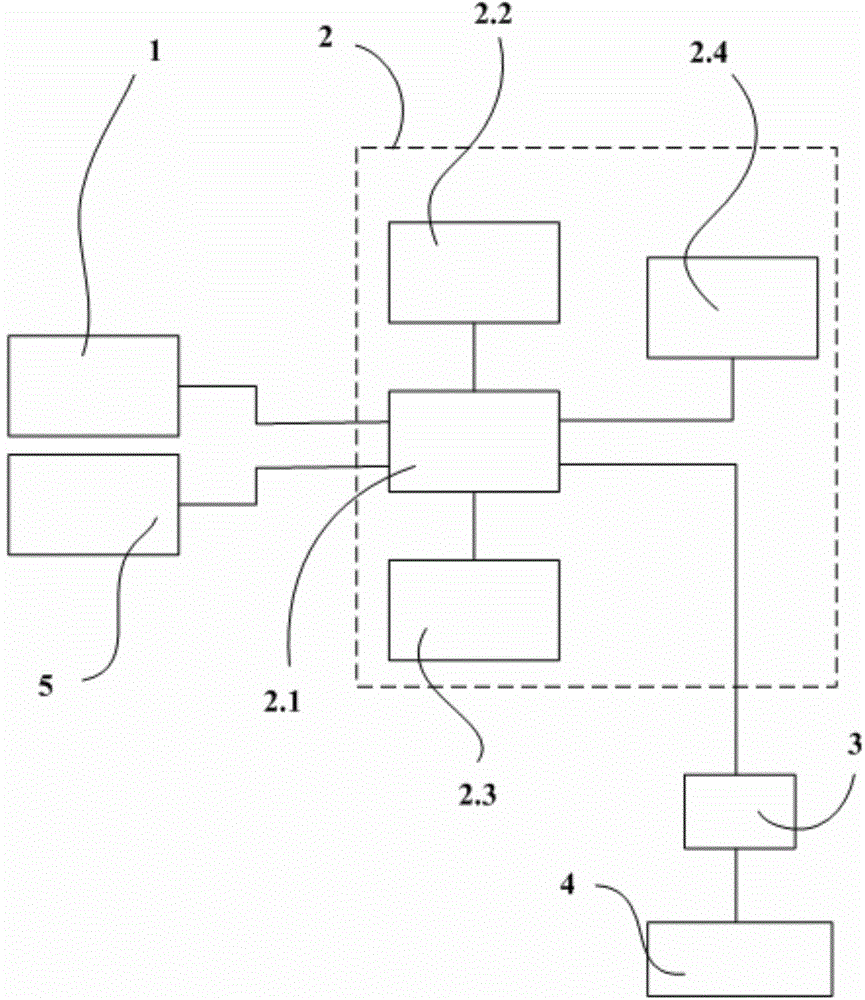

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] A kind of engine cylinder airtightness testing method of the present invention comprises:

[0035] Step A, detecting the top dead center of the cylinder to be tested of the electronically controlled engine to be tested on the vehicle to be tested;

[0036]Step B, within one cycle of the crankshaft rotating at a certain speed, record the time t it takes for the crankshaft to turn from the α° position before the top dead center detected in the above step A to the top dead center detected in the above step A 1 , and record the time t it takes for the crankshaft to turn from the top dead center detected in the above step A to the β° position after the top dead center detected in the above step A 2 ;

[0037] Step C, respectively calculate the crankshaft in the above time length t 1 and duration t 2 Angular velocity of internal rotation ω 1 , ω 2 , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com