Automatic ascending protection device for drill bit in incoming coal sampling machine

An automatic protection and sampling machine technology, applied in the direction of sampling devices, supporting machines, mechanical equipment, etc., can solve problems such as safety accidents, sampling machine derailment, damage to transport vehicles, etc., to achieve easy implementation, simple structure, and guaranteed sampling success rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

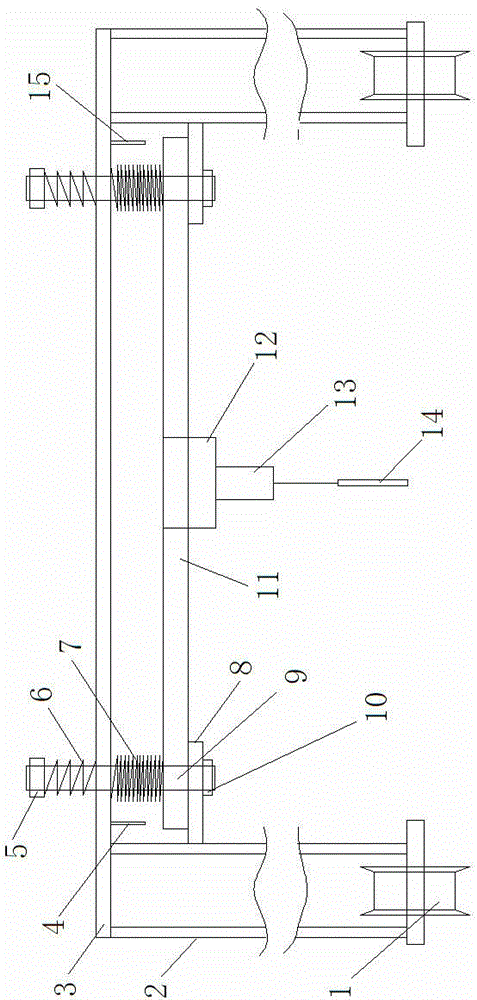

[0007] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

[0008] The direction in the present invention is defined as: the forward and backward direction of the guide rail wheel is the longitudinal direction, the length direction of the crossbeam is the horizontal direction, and the left and right sides are facing figure 1 When defined.

[0009] The present invention will be further described in detail in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 1: left guide rail wheel; 2: left gantry vertical frame; 3: crossbeam; 4: left mechanical trigger switch; 5: nut on the left guide post; 6: Left anti-bias spring; 7: Left compression spring; 8: Left limit structure; 9: Left guide post; 10: Left guide post lower nut; 11: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com