Lens Assembly

一种成像镜头、透镜的技术,应用在成像镜头领域,能够解决降低成本等问题,达到降低生产成本、解决热效应问题、良好光学性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

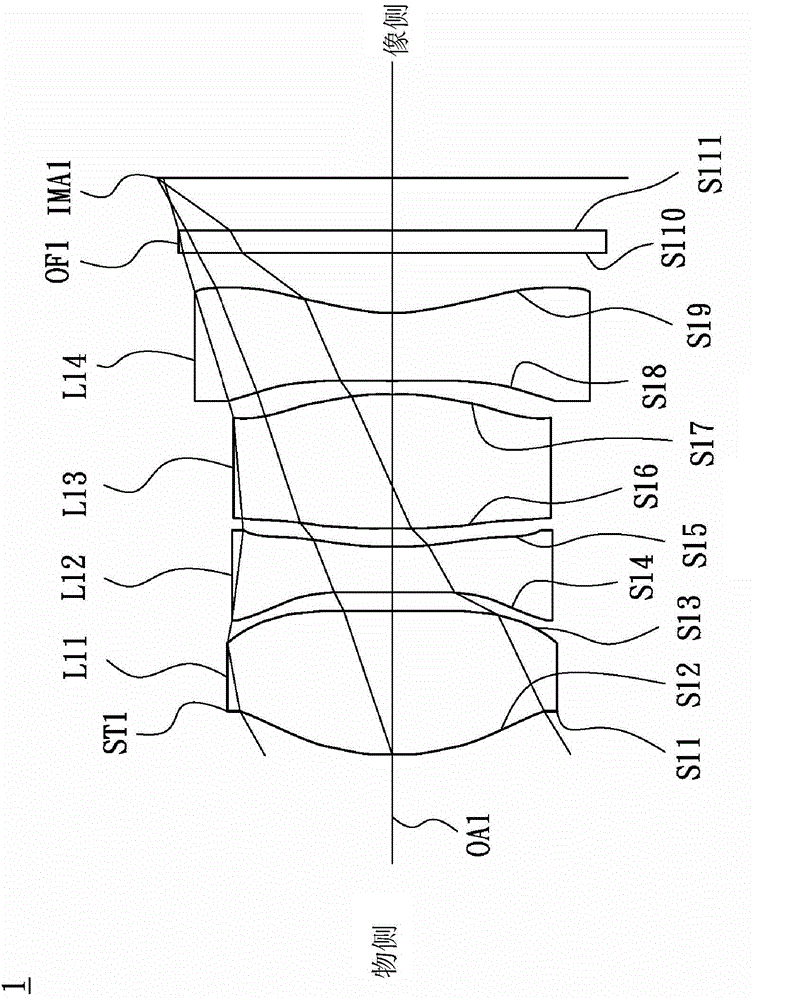

[0034] see figure 1 , figure 1 It is a schematic diagram of lens configuration and optical path according to the first embodiment of the imaging lens of the present invention. The imaging lens 1 sequentially includes a diaphragm ST1, a first lens L11, a second lens L12, a third lens L13, a fourth lens L14 and an optical filter OF1 from the object side to the image side along the optical axis OA1. During imaging, the light from the object side is finally imaged on the imaging surface IMA1. The first lens L11 is a biconvex lens made of plastic material, and its object side S12 and image side S13 are both aspheric surfaces. The second lens L12 is a biconcave lens made of plastic material, and its object side S14 and image side S15 are both aspheric surfaces. The third lens L13 is a biconvex lens made of glass, and its object side S16 and image side S17 are both aspheric surfaces. The fourth lens L14 is made of plastic material, the object side S18 is concave, the image side S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com