Yttrium oxide laser transparent ceramic material with incentive elements in continuous gradient distribution and preparation method thereof

A gradient distribution and ceramic material technology, applied in the field of materials, can solve the problems of not being able to fundamentally solve the problem of thermal effect, not completely eliminating the interface, and not being able to eliminate the influence of interface thermal effect, so as to eliminate thermal stress and its influence on the laser beam, beam Improved quality and average power at lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare Y (NO 3 ) 3 solution, and adjust the pH=1 with a nitric acid solution with a concentration of 0.1M; prepare Yb with a molar concentration of 0.01M (NO 3 ) 3 solution, and adjust the pH=1 with a nitric acid solution with a concentration of 0.1M; prepare a urea solution with a molar concentration of 0.5M;

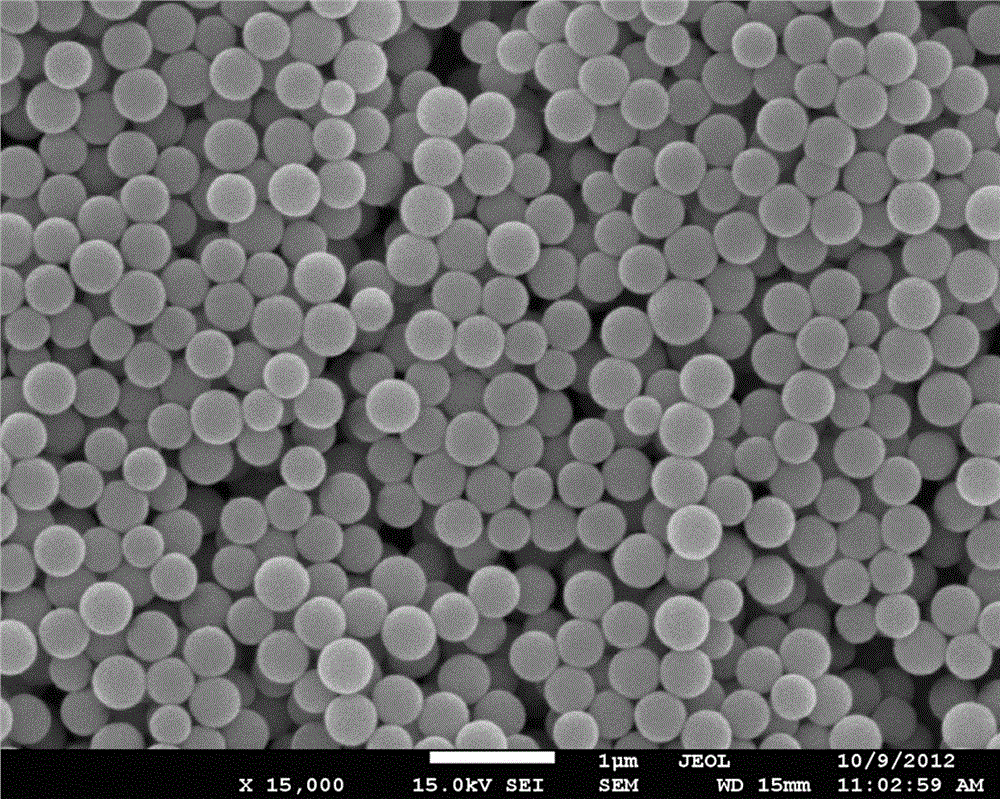

[0047] Preparation of Yb:Y 2 o 3 Spherical nano powder:

[0048] Will Y (NO 3 ) 3 solution, Yb (NO 3 ) 3 Solution and urea solution are mixed evenly to make rare earth doped yttrium oxide mother salt solution, wherein Y(NO 3 ) 3 and Yb (NO 3 ) 3 The molar ratio of Y (NO 3 ) 3 and Yb (NO 3 ) 3 The molar ratio of the total amount of urea to urea is 1:10; the rare earth-doped yttrium oxide mother salt solution is heated to 90°C within 0.5 hours, and kept for 5 hours to obtain a white precipitate; the white precipitate is collected by filtration and washed, and the cleaning is first with water Wash and filter the white precipitate, and then wash an...

Embodiment 2

[0060] Prepare the molar concentration of 0.5M Y (NO 3 ) 3 solution, and adjust the pH=5 with a nitric acid solution with a concentration of 1M; prepare a molar concentration of 0.5M Yb (NO 3 ) 3 solution, and adjust the pH=5 with a nitric acid solution with a concentration of 1M; prepare a urea solution with a molar concentration of 2M;

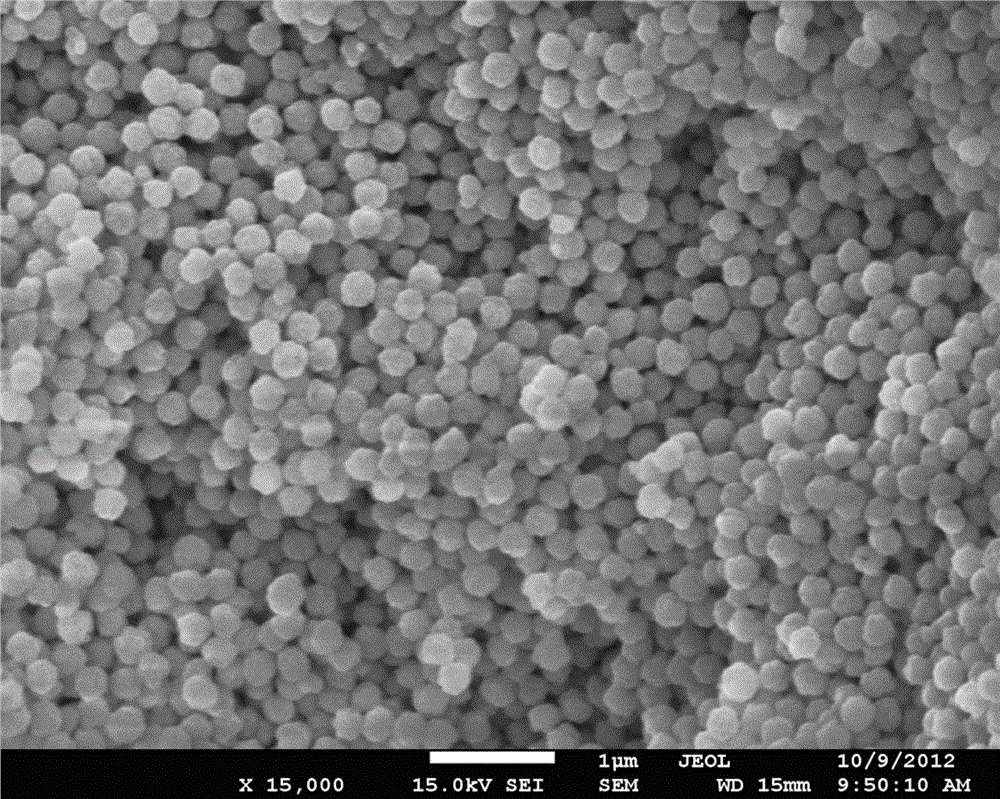

[0061] Preparation of Yb:Y 2 o 3Spherical nano powder:

[0062] Will Y (NO 3 ) 3 solution, Yb(NO 3 ) 3 Solution and urea solution are mixed evenly to make rare earth doped yttrium oxide mother salt solution, wherein Y(NO 3 ) 3 and Yb (NO 3 ) 3 The molar ratio of Y (NO 3 ) 3 and Yb (NO 3 ) 3 The molar ratio of the total amount of urea to urea is 1:30; the rare earth-doped yttrium oxide mother salt solution is heated to 82°C within 1 hour, and kept for 3 hours to obtain a white precipitate; the white precipitate is collected by filtration and washed. Wash and filter the white precipitate, then wash and filter the white precipi...

Embodiment 3

[0074] Prepare the molar concentration of 0.1M Y (NO 3 ) 3 solution, and adjust the pH=35 with 0.2M nitric acid solution; prepare Yb (NO 3 ) 3 solution, and adjust the pH=3 with a nitric acid solution with a concentration of 0.2M; prepare a urea solution with a molar concentration of 1M;

[0075] Preparation of Yb:Y 2 o 3 Spherical nano powder:

[0076] Will Y (NO 3 ) 3 solution, Yb(NO 3 ) 3 Solution and urea solution are mixed evenly to make rare earth doped yttrium oxide mother salt solution, wherein Y(NO 3 ) 3 and Yb (NO 3 ) 3 The molar ratio of Y (NO 3 ) 3 and Yb (NO 3 ) 3 The molar ratio of the total amount of urea to urea is 1:10; the rare earth-doped yttrium oxide mother salt solution is heated to 98°C within 4 hours, and kept for 0.5 hours to obtain a white precipitate; the white precipitate is collected by filtration and washed. Wash and filter the white precipitate, then wash and filter the white precipitate with absolute ethanol until there is no ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com