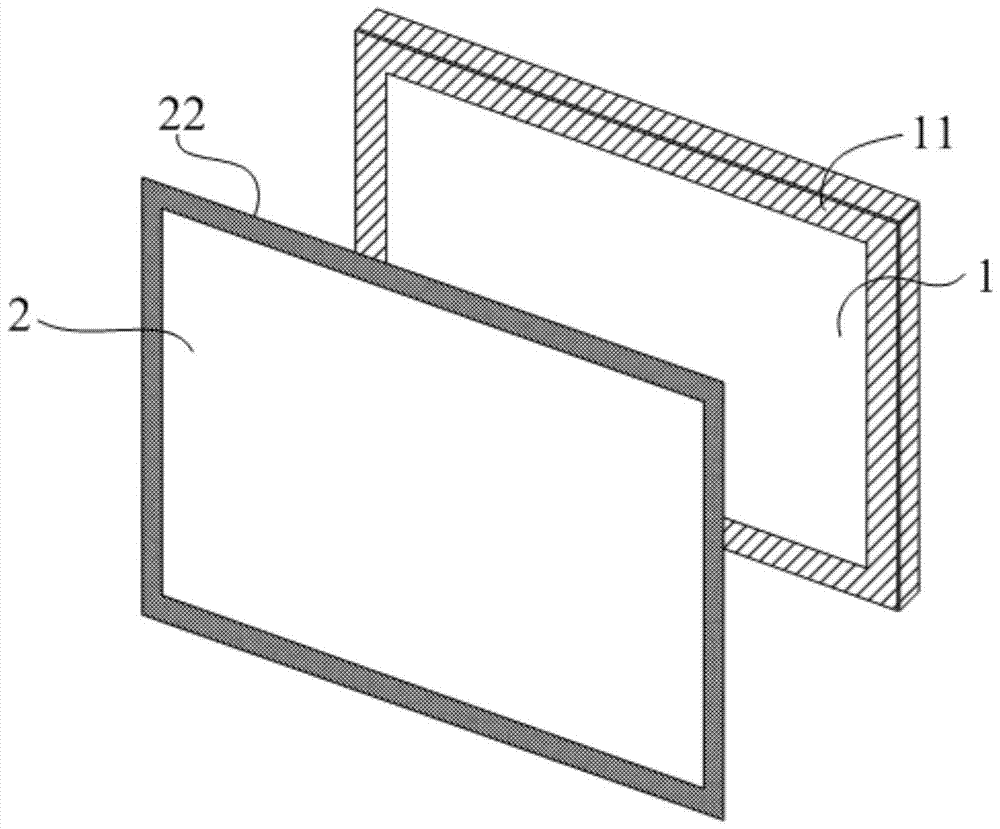

Non-fully laminated screen with waterproof fog function and manufacturing method thereof

A production method and a fully-fitted technology, applied in the field of display screens, can solve problems such as affecting consumers' use and visual effects, and achieve the effects of simple structure, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

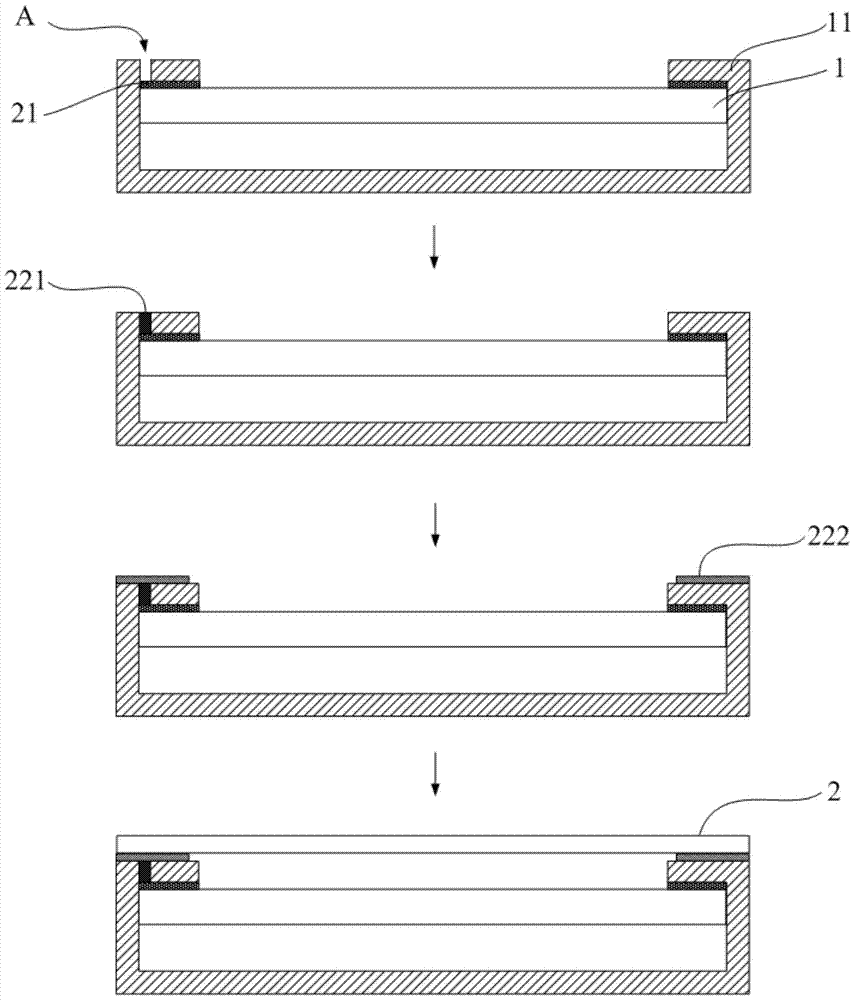

[0039] Such as image 3 As shown, in a preferred embodiment, the non-fully laminated screen with waterproof fog function of the present invention is laminated through the following steps:

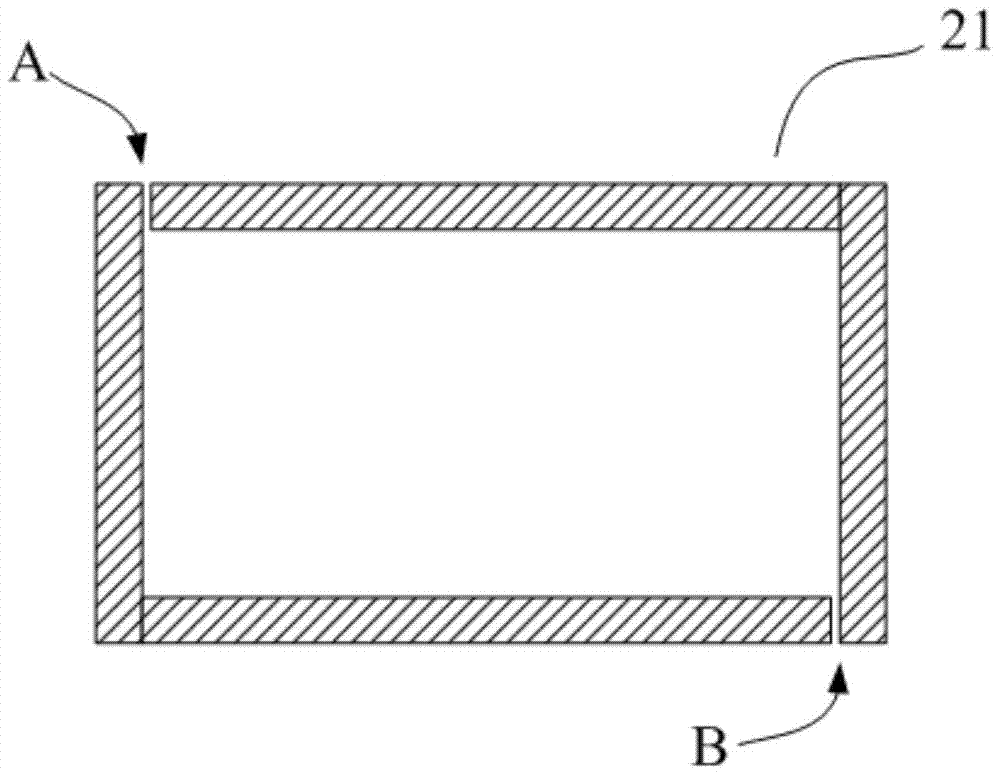

[0040] 1. Take the inner screen 1 with simple packaging, wherein the edge part of the inner screen protection structure 11 is connected with the inner screen 1 through a viscous structure 21 such as water glue or double-sided adhesive; on the surface of the inner screen 1, the inner screen protection structure 11 Discontinuous with at least one gap such as gap A. Since the viscous structure 21 under the gap A in the case of simple packaging does not completely cover the gap A, the airflow can pass through the gap A to reach the surface of the inner screen 1 .

[0041] Cleaning the upward facing surface of the inner screen protection structure 11 (ie the surface to be attached to the outer screen 2 ) includes cleaning its gap, such as gap A. Cleaning methods, for example, wipe with alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com