Calculating method for envelop feature lines of rotary cutter based on enveloping theory and division of longitudes

A calculation method and a rotary-type technology, applied in the fields of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems such as the state and error of the effective characteristic line that cannot be calculated, avoid the iterative process, improve the calculation accuracy, The effect of improving computational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0089] See figure 1 — Figure 4 , the present invention a kind of rotary tool envelope feature line calculation method based on envelope theory and meridian division, it comprises the following steps:

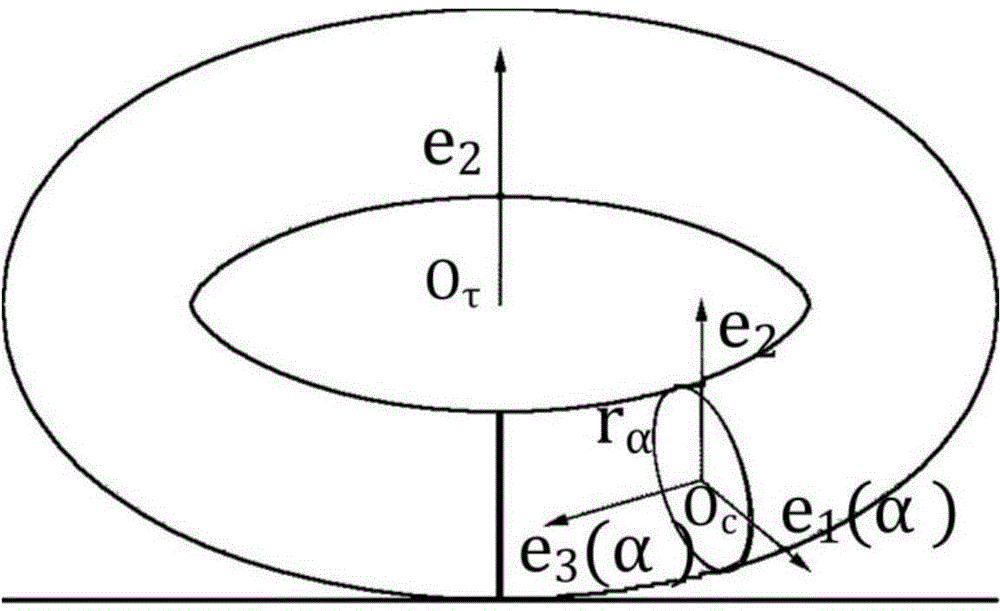

[0090] Suppose the parameter equation of the workpiece surface is S(u, v), the tool surface corresponding to the current tool position is τ, the radius of the center circle of the tool is R, and the radius of the meridian arc is r.

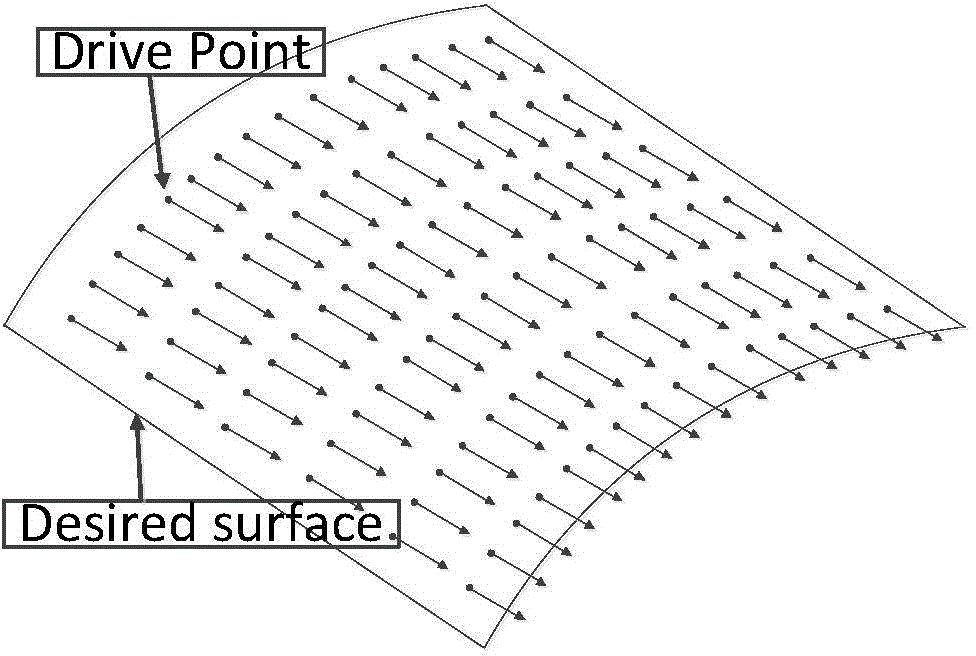

[0091] Step 1: Establish a vector field on the design surface according to the planned direction of the tool path.

[0092] Plan the feed direction corresponding to each driving point on the design surface. If the feed direction of the tool at the positioning point S(u, v) is Λ(u, v), then Λ(u, v) is a vector field established on the design surface. where Λ(u, v) is a unit vector, and satisfies

[0093]

[0094] That is, Λ(u, v) falls in the tangent plane of S(u, v).

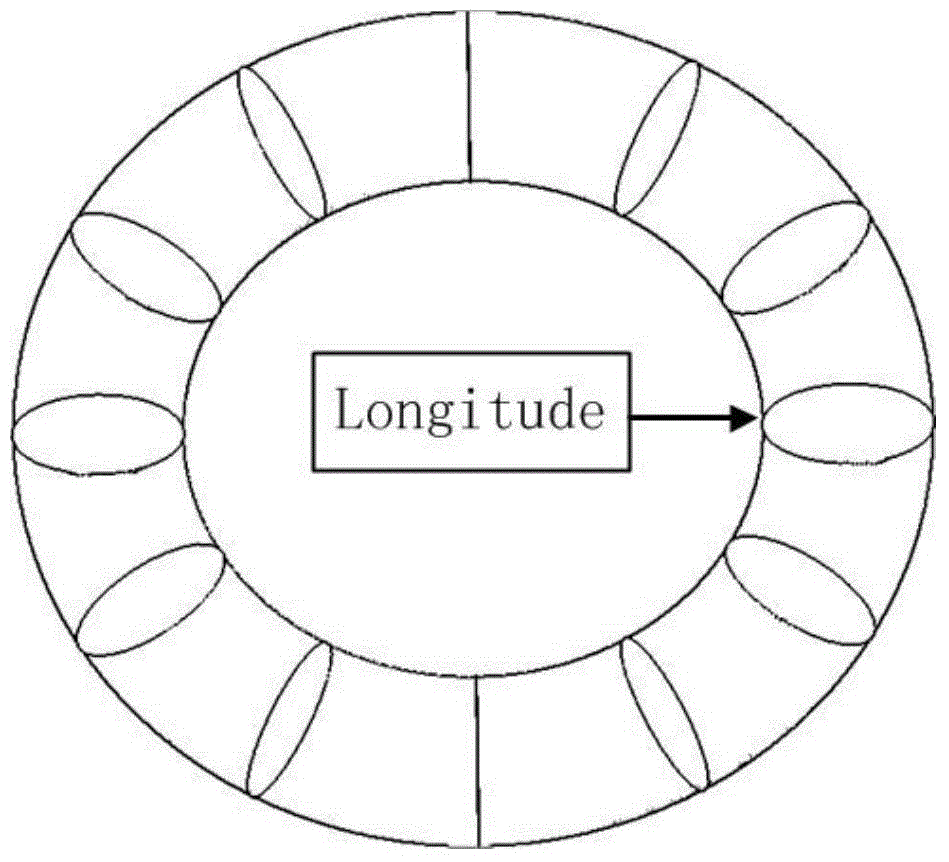

[0095] Step 2 divides the tool by meridian, and establishes a local coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com