High temperature transponder tag and method of use

A technology of transmitters and transponders, applied in the field of high temperature resistant transponder labels, which can solve problems such as impossibility and difficult data exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

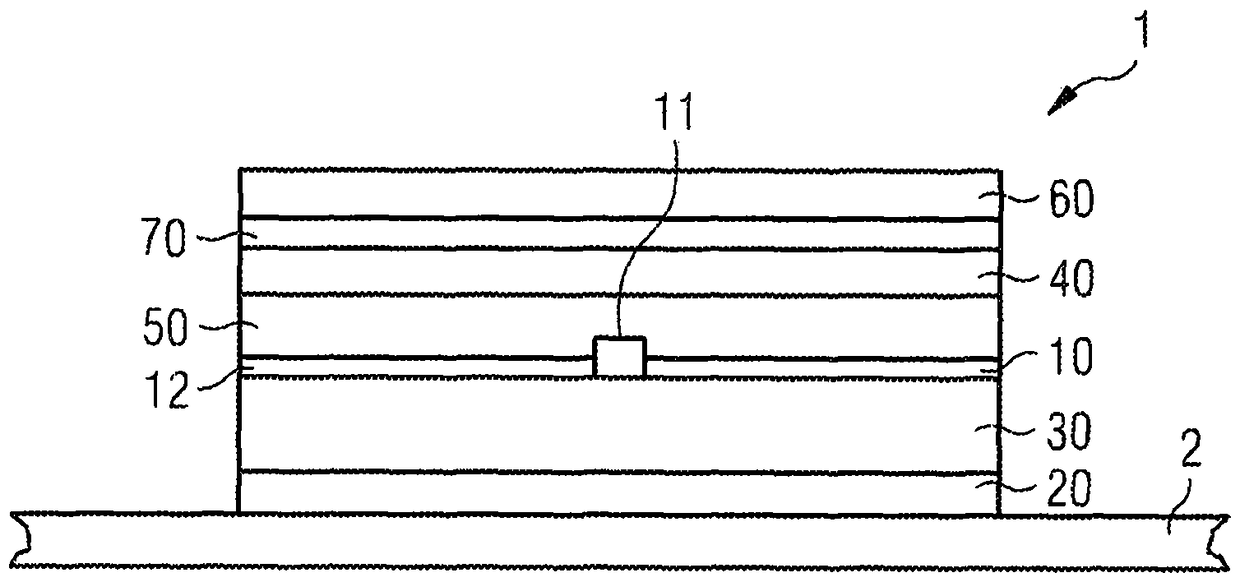

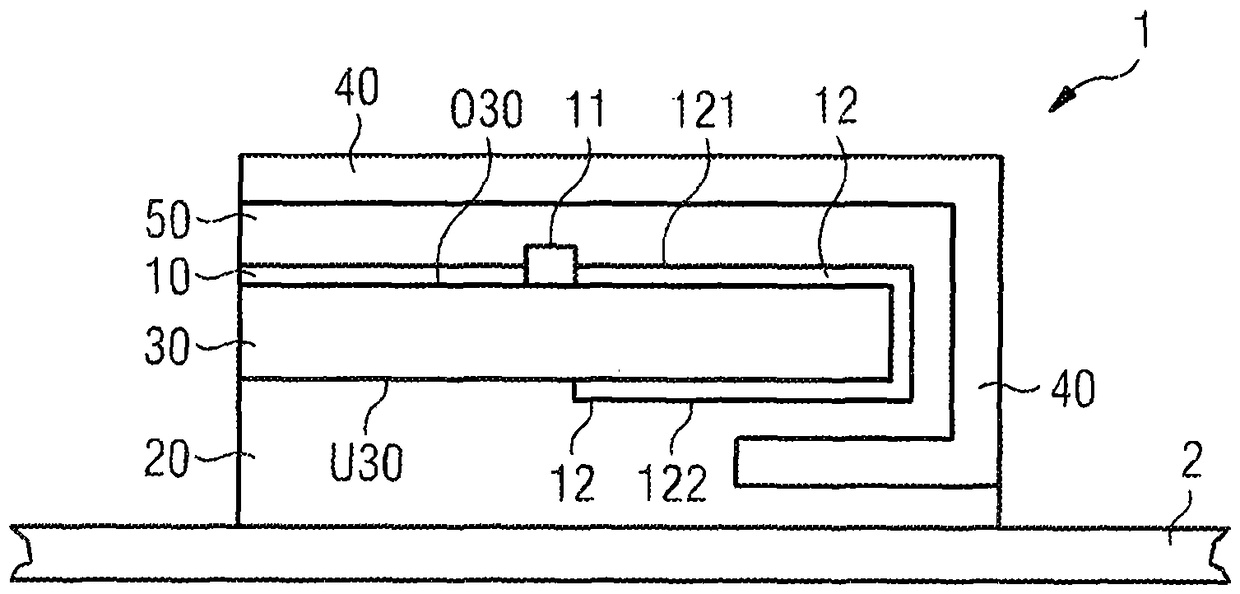

[0044] figure 1 A first embodiment of a high temperature resistant transponder label 1 suitable for sticking to a conductive substrate is shown. Due to the heat resistance of the materials used for the individual layers of the transponder label, the transponder label is particularly suitable for use at temperatures between 125°C and 400°C, e.g. The temperature that occurs during the drying process of a lacquer on a conductive substrate.

[0045] The heat-resistant transponder tag 1 comprises a transponder 10 with a chip 11 and an antenna structure 12 connected to the chip. In addition, the transponder label 1 has an adhesive material layer 20 for sticking the transponder label 1 on a conductive substrate and for isolating the transponder device from the conductive substrate and arranging the transponder device thereon. Spacer layer 30 of transponder 10 . The spacer layer 30 has an underside U30 on which the layer of adhesive material 20 is arranged. Furthermore, the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com