Bulk cargo material yard material pile management method

A management method and stockpile technology, applied in the computer field, can solve the problems of low stockyard management and control efficiency, achieve high stockyard utilization, and improve management efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

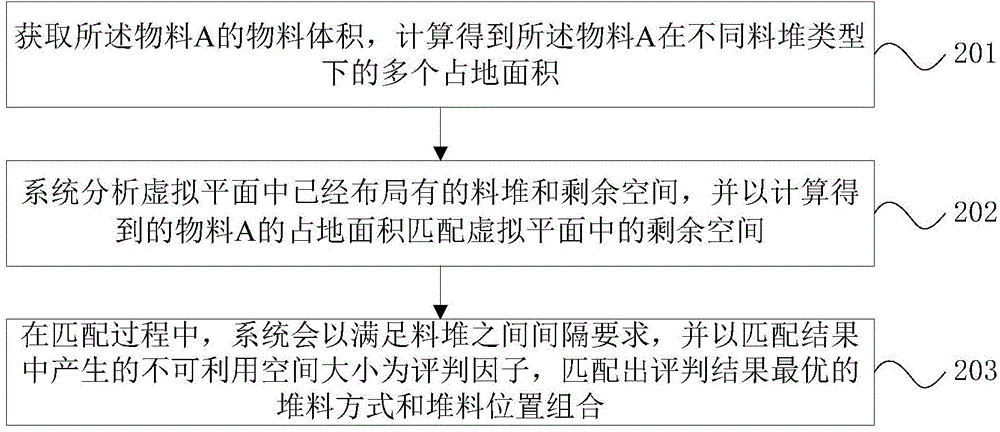

[0015] Such as figure 1 Shown is a flow chart of a method for managing bulk stockyards and stockpiles provided by the present invention. A virtual plane of stockyards is created in the system, and corresponding stockpiles are laid out on the virtual plane. In the system, the stockpiles include Footprint, height, stockpile type attributes. When a new material A is transported and needs to be stored on the stockyard, the method includes the following steps:

[0016] In step 201, the material volume of the material A is obtained, and multiple floor areas of the material A under different stockpile types are calculated.

[0017] The pile type includes pile bottom type and stacking method: among them, the pile bottom type includes: square pile bottom and circular pile bottom; the square pile bottom also includes herringbone and trapezoidal stacking methods.

[0018] In step 202, the system analyzes the stockpile and remaining space already laid out in the virtual plane, and match...

Embodiment 2

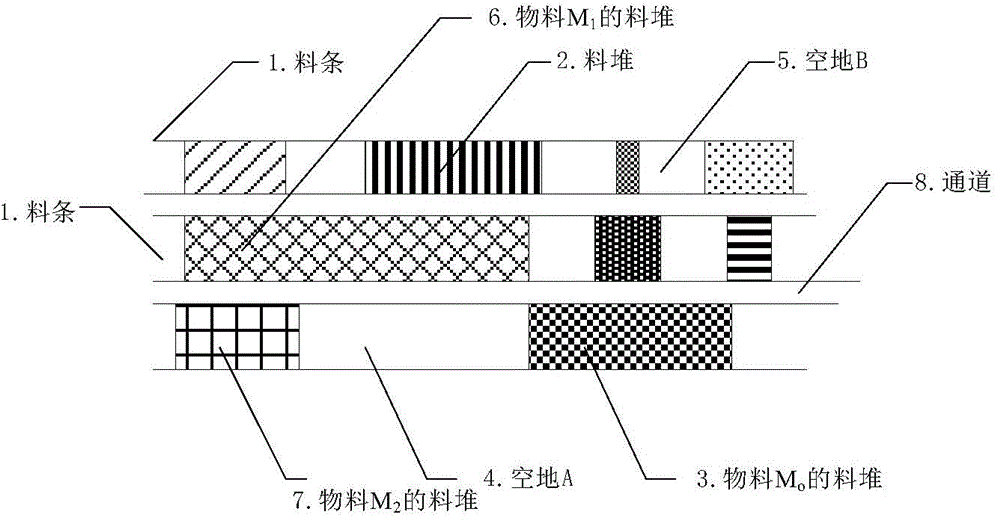

[0027] Such as figure 2 Shown is a schematic distribution diagram of a bulk stockyard stockpile provided by the embodiment of the present invention, figure 2 It only provides an arrangement method of bulk storage yards. In the prior art, there may be field type, circle type, etc., which will not be described one by one here. From figure 2 It can be seen from the figure that there are usually material strips 1 specially used for stacking materials in the stockyard, various stockpiles 2, 3, 6, 7, and open spaces 4, 5 between the stockpiles, and the space between the material strips. Channel 8, the channel 8 is usually used to transport the reclaimer and transport vehicles. Therefore, in Embodiment 1, when material A is about to come in, the system provided by the embodiment of the present invention will calculate how to effectively utilize figure 2 In order to achieve the purpose of optimizing the utilization rate of the stockyard.

Embodiment 3

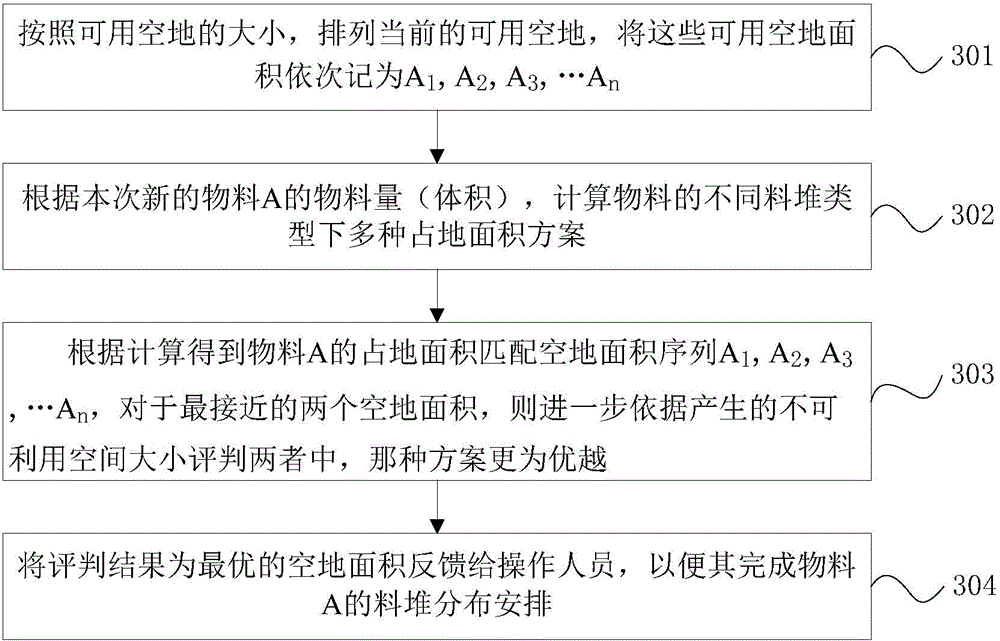

[0029] This embodiment will describe the method proposed by the present invention in combination with the method of embodiment 1 and the specific environment of implementation 2, and its implementation in a specific implementation environment, specifically including:

[0030] When material A is transported to such as figure 2 Before the stockyard shown, the system provided by the embodiment of the present invention has established and stored all stockpile information stored in the current stockyard and the distribution of each stockpile. The distribution includes: the location of the stockpile, The size of the occupied space, the size of the available space and so on.

[0031] In step 301, the current available open spaces are arranged according to the size of the available open spaces, and the areas of these available open spaces are sequentially recorded as A 1 ,A 2 ,A 3 ,…A n .

[0032] Since the available vacant space may change every day during the maintenance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com