Wire Twisting Fixtures, Twisting Machines and Twisting Systems

A wire twisting machine and wire twisting technology, which is applied in the field of wire twisting machines, wire twisting systems, and wire foot twisting fixtures. It can solve the problems of workers' hand strain, wire feet re-separation, and the inability to apply torque evenly to the wire feet, so as to reduce labor intensity. , prevent re-separation, and realize the effect of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

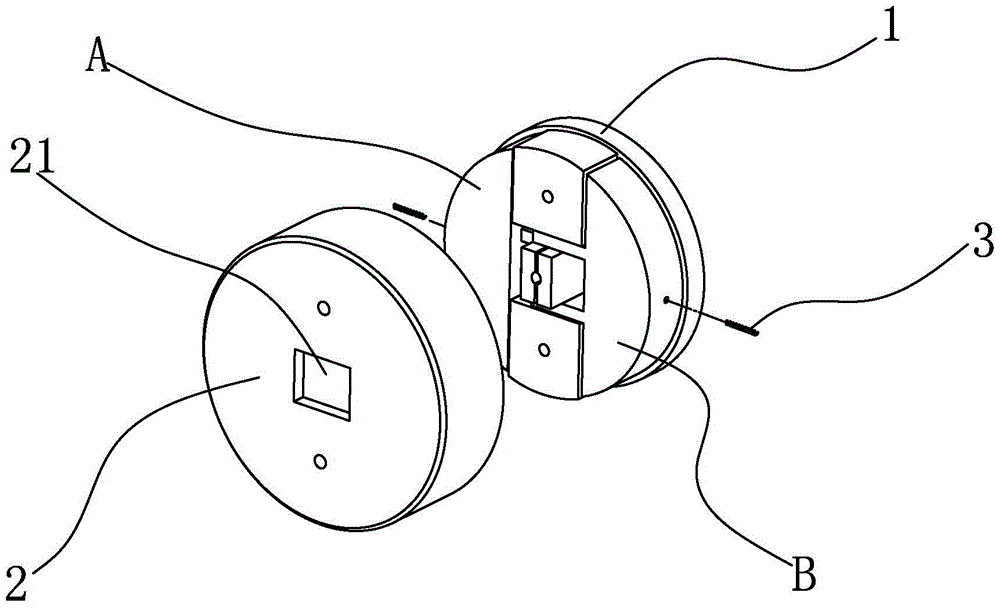

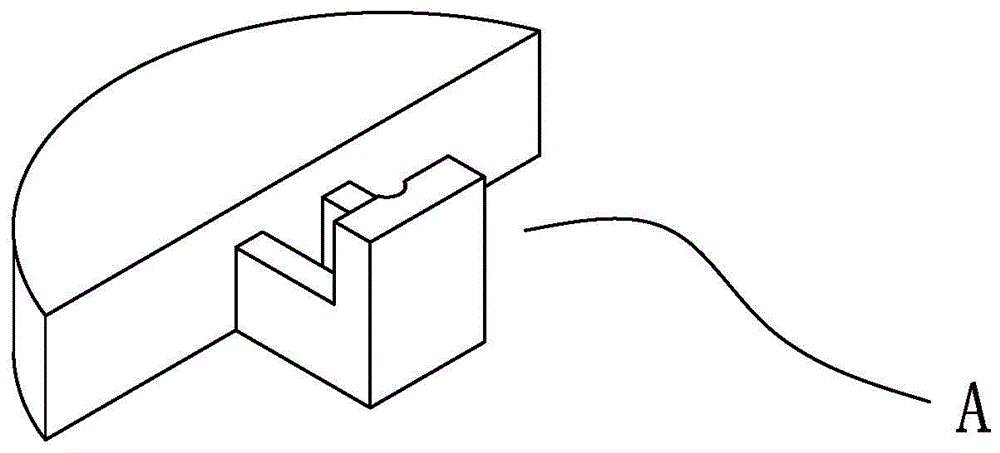

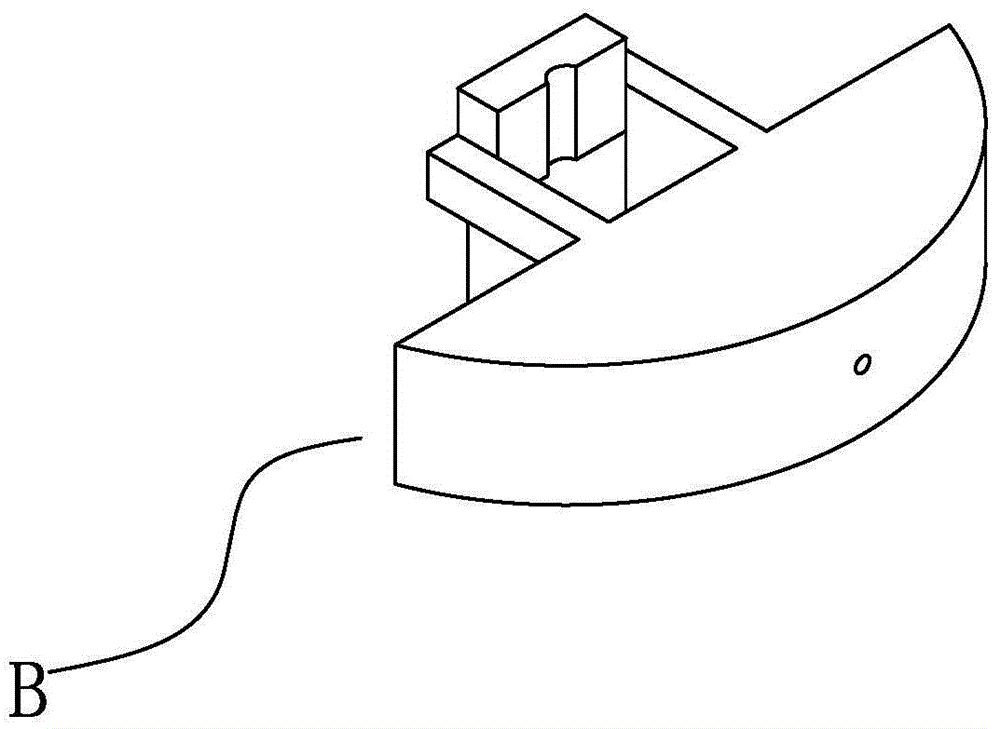

[0024] Such as Figure 1~4 As shown, a wire twisting clamp includes a clamp base 1 , a cover body 2 , a clamping block A, a clamping block B, and a return spring 3 . The clamp base 1 is circular and can rotate around the central axis. Two connecting columns are symmetrically arranged on the clamp base 1 with respect to the central axis. The cover 2 is fixedly connected to the clamp base 1 through the connecting columns. A cavity is formed between the clamp seat 1 and the cover body 2 , and an opening 21 is provided at the intersection of the surface of the cover body 2 and the central axis for inserting the wire legs into the cavity. The clamping block A and the clamping block B are symmetrically arranged in the cavity with respect to the central axis, and can slide and reset in the radial direction. Clamp A and clamp B are both equipped with a counterweight and a clamping body, the clamping body is connected with the counterweight through a connecting rod, the clamping body ...

Embodiment 2

[0026] A thread leg twisting fixture includes a fixture seat, a clamping block C, a clamping block D, a clamping block E, and a return spring. The clamp seat is in the shape of a regular hexagon, and the clamp blocks C, D, E are arranged on the clamp seat at intervals of 120° around the central axis, and are provided with a clamping body and a trapezoidal counterweight. The counterweights are arranged at intervals of 180° around the central axis, and the clamping body and the counterweights are connected through connecting rods. The clamp seat is provided with a guardrail on the bottom edge of each counterweight body to prevent the clamp block from falling off, and the return spring is arranged between the counterweight body and the guardrail. All the other designs are the same as in Example 1.

[0027] A wire twisting machine, comprising a frame, the upper surface of the frame is provided with the wire leg twisting fixture as described above, the frame is provided with a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com