Outward rotation permanent magnet brushless motor

A permanent magnet brushless motor, external rotation technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of poor support frame design, low service life of parts, wear and tear, etc., to solve the problem of poor structural rigidity , Reduce bearing clearance, improve the effect of improper bearing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

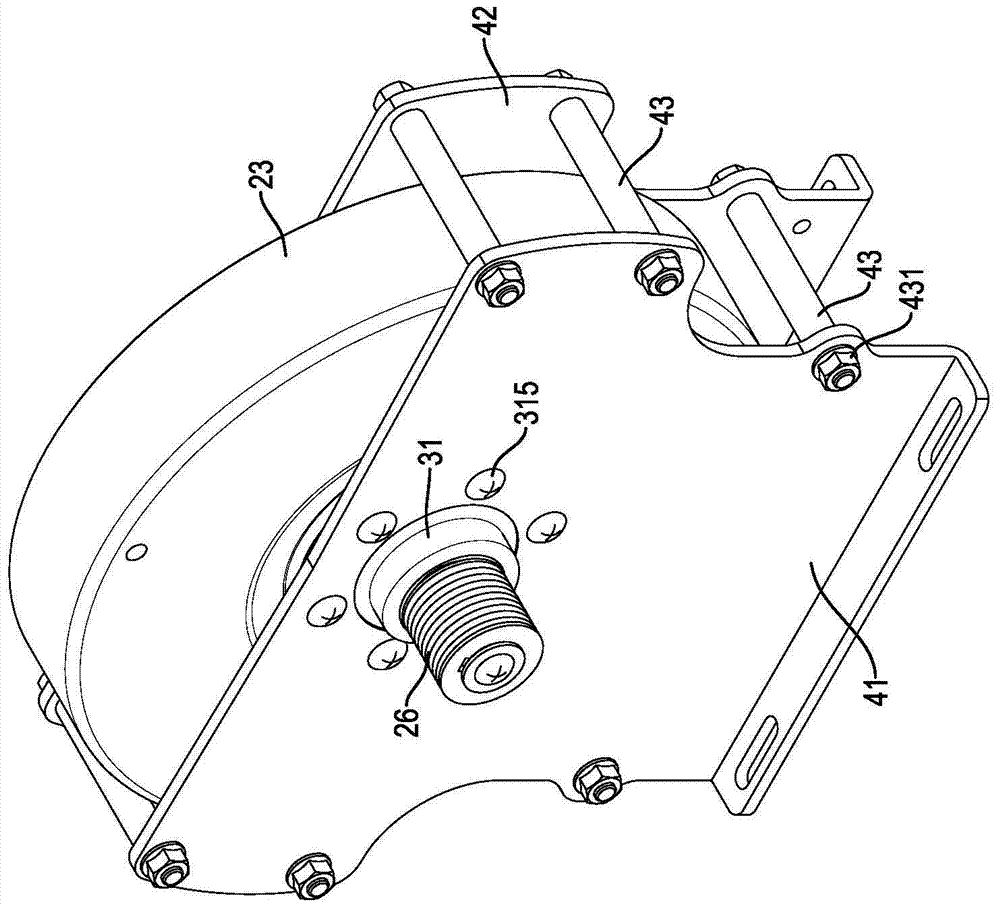

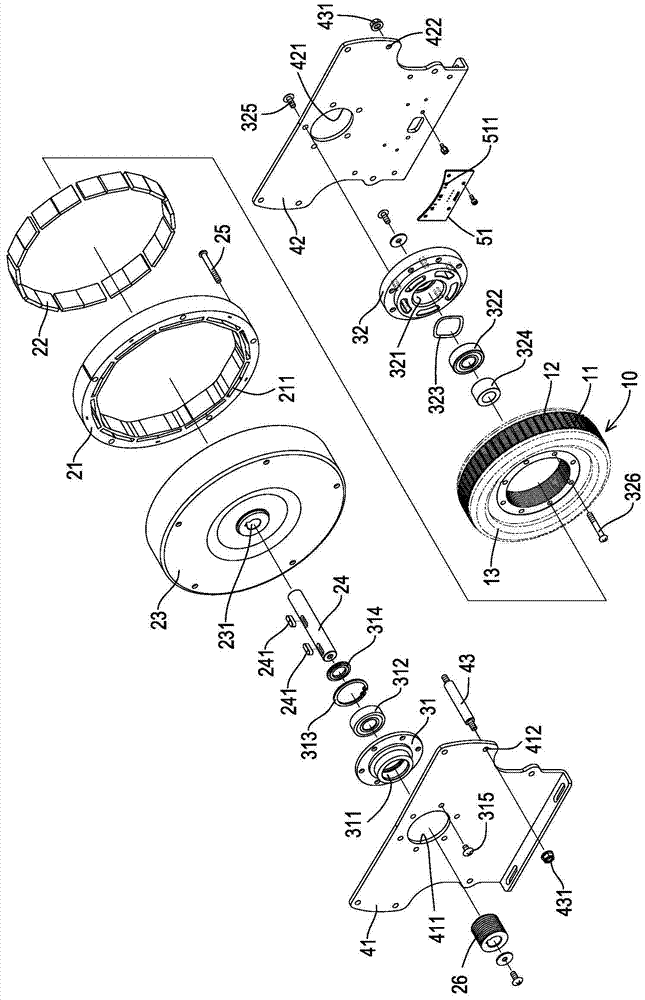

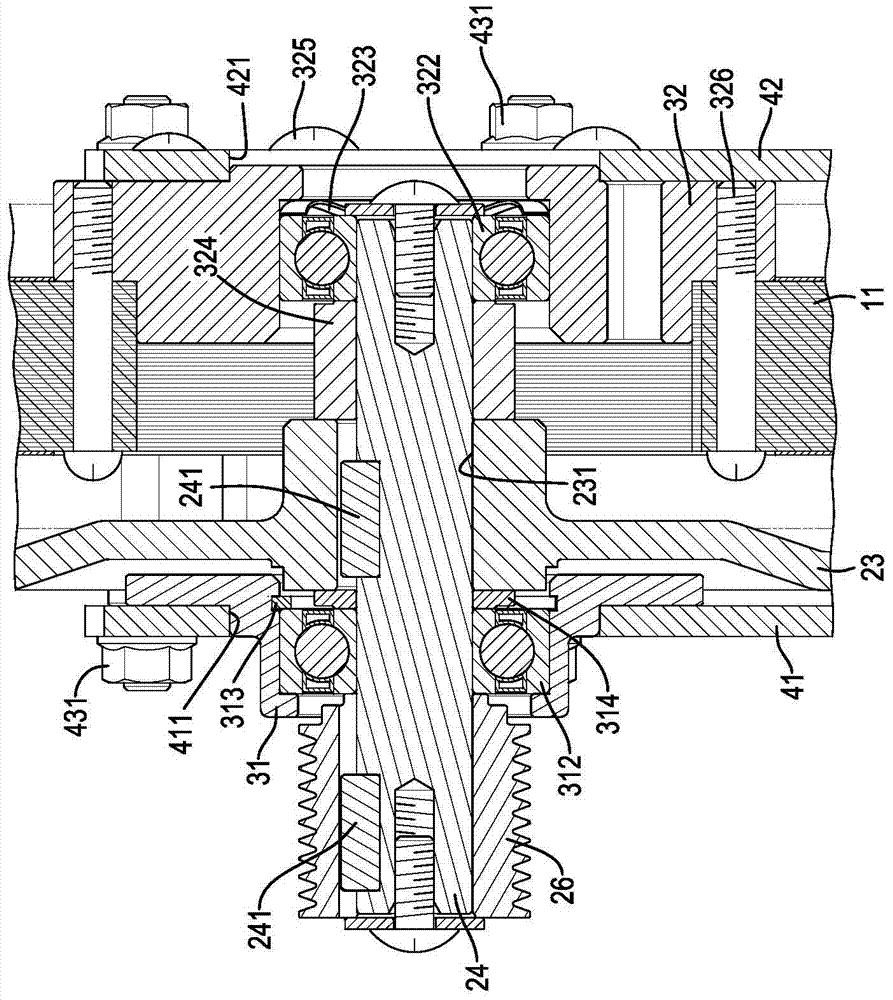

[0062] For a preferred embodiment of the present invention, please refer to Figures 1 to 3 Shown, be to be provided with a rotatable rotor 21 on the outer ring of a certain stator 10 periphery, be provided with a plurality of permanent magnets 22 in this rotor 21, and be fixedly provided with a flywheel 23 on the outside of rotor 21 periphery, this flywheel 23 and stator A front support frame 41 and a rear support frame 42 are respectively provided on the opposite two outer sides of the stator 10. The stator 10 is connected to the rear support frame 42. The end of the front support frame 41 opposite to the flywheel 23 is provided with a front bearing seat 31. The end of the rear supporting frame 42 opposite to the stator 10 is provided with a rear bearing seat 32 , and a drive shaft 24 is penetrated between the front bearing seat 31 and the rear bearing seat 32 , and the drive shaft 24 is connected to the flywheel 23 .

[0063] The stator 10 is mainly composed of a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com