Syringe type spray container

A technology for syringes and containers, applied in the field of syringe-type ejection containers, which can solve the problems of inappropriate spraying of a small amount of content liquid and poor convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

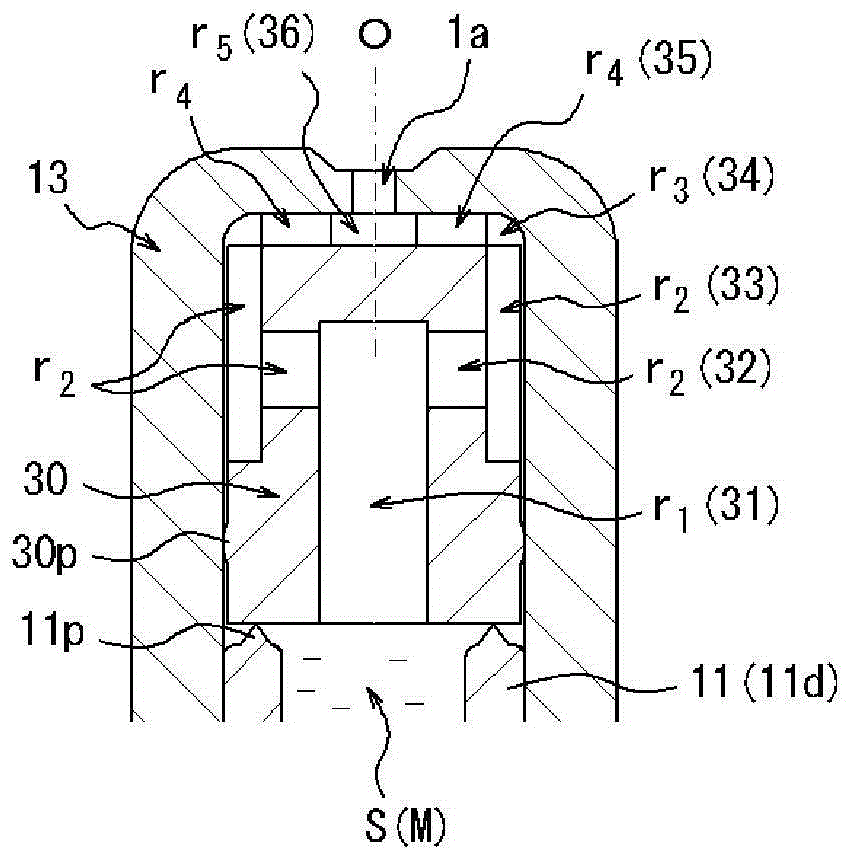

[0072] 22 piston (second embodiment) 30 rotating member (first embodiment)

[0073] 31 Internal passage 32 Through hole

[0074] 33 slots 34 cutouts

[0075] 35 Rotary tank 36 Confluence tank

[0076] 40 rotating member (second embodiment) 40a main body

[0077] 40b Insertion part 40c Cutout part

[0078] 41a internal passage 41b internal passage

[0079] 42 through holes 43 slots

[0080] 44 cutouts 45 rotation slots

[0081] 46 Merge trough 47 The second trough

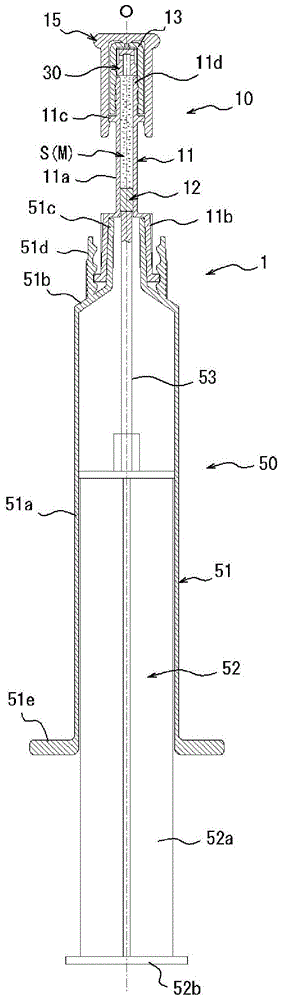

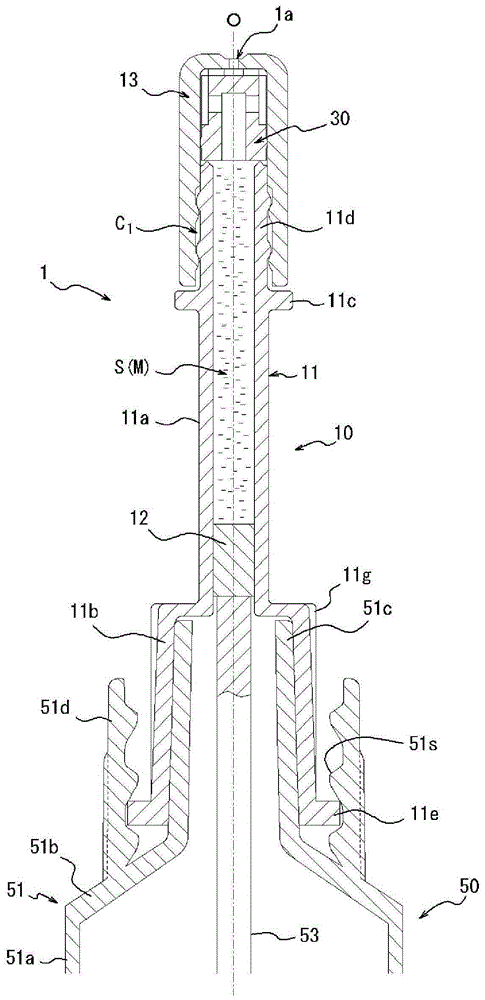

[0082] 48 engaging part 50 operating part

[0083] 51 syringe 51a main body

[0084] 51b shoulder 51c front barrel

[0085] 51d installation barrel 52 shaft for operation

[0086] 53 piston rod (rod) r 1 Introduce flow path

[0087] r 2 Branch flow path r 3 circular flow path

[0088] r 4 Rotary flow path r 5 confluence department.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com