Retention aid and method for producing paper using same

A manufacturing method and technology of retention aids, applied in the direction of addition of retention aids, papermaking, paper, etc., can solve the problems of reducing the uniformity of paper thickness, complicated operability of paper machines, and increasing the total addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0065] (Examples 1-3, Comparative Examples 1-3 and Conventional Examples 1-3)

[0066] Retention aids were prepared using cationic and anionic polymer compounds shown in Tables 1 to 9 below. In addition, the cationic and anionic polymer compounds used in each of the Examples, Comparative Examples, and Conventional Examples are as follows.

[0067] Cationic polymer compound A: acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer (linear structure)

[0068] Cationic polymer compound B: acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer (branched chain structure)

[0069] Anionic polymer compound A: acrylamide-sodium acrylate copolymer (linear structure)

[0070] Anionic polymer compound B: acrylamide-sodium acrylate copolymer (branched chain structure)

[0071] [Measurement of viscosity average molecular weight]

[0072] The viscosity-average molecular weight of the polymer compound was obtained by measuring the intrinsic viscosity according to the in...

Embodiment 4 and comparative example 4

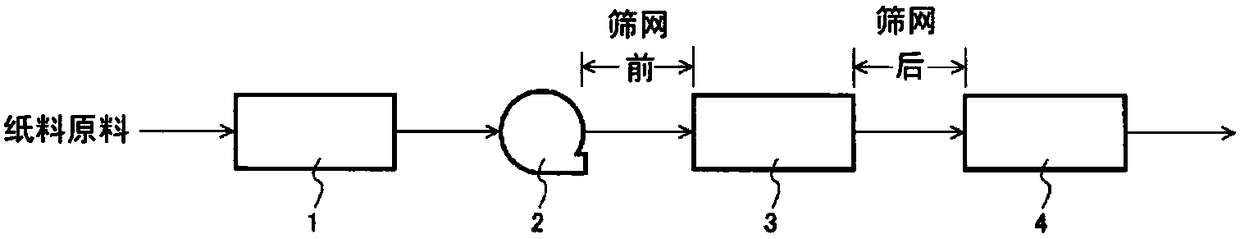

[0151] Under the conditions identical with embodiment 1-10, 1-12, 2-9, 2-12 and 3-5 and comparative example 1-11, 1-12 and 2-9, to paper machine (coating base paper Equipment, papermaking speed: 1300m / min) performed a retention aid addition test based on actual equipment. In the actual equipment, aluminum sulfate is added before the seed box, alkyl ketene dimerization system sizing agent (AKD) is added in the seed box, and cationic polyacrylamide paper strength agent is added after the seed box. Calcium carbonate as a filler is added before the slurry pump, and retention aids are added before the screen, after the screen or before and after the screen. The obtained results are shown in Table 10.

[0152] [Table 10]

[0153]

[0154] It can be seen from Table 10 that the retention aid addition test based on the Brit type dynamic water drainage tester has the same result as the retention aid addition test based on the actual equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com