Unloading methods for aqueous bulk materials

A technology of bulk material and unloading machine, which is applied in the direction of bulk cargo, loading/unloading, cargo handling equipment, etc. It can solve problems such as unloading failures and achieve the effect of improving the efficiency of unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

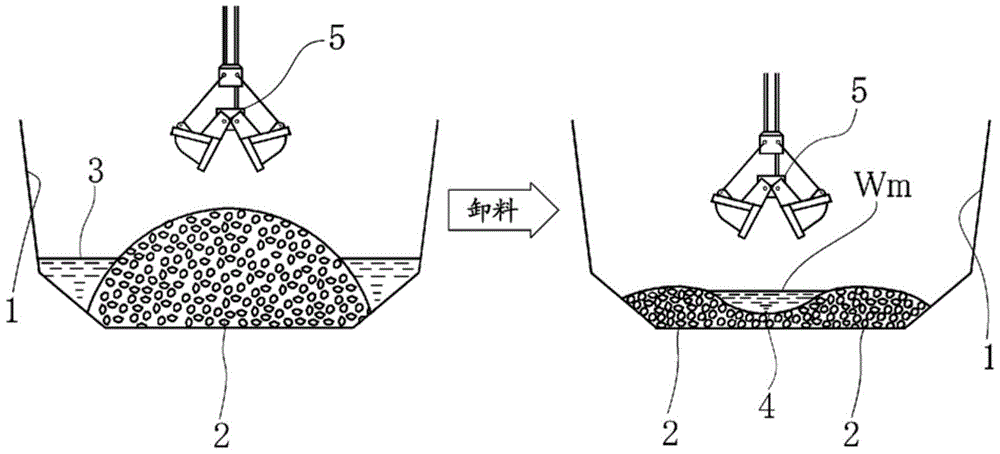

[0101] Taking the Carajás iron ore as an example for illustration, the Carajás iron ore is iron ore that is separated from bulk materials during the import process, and is in a state of water gushing at the bottom of the cabin when it arrives at home.

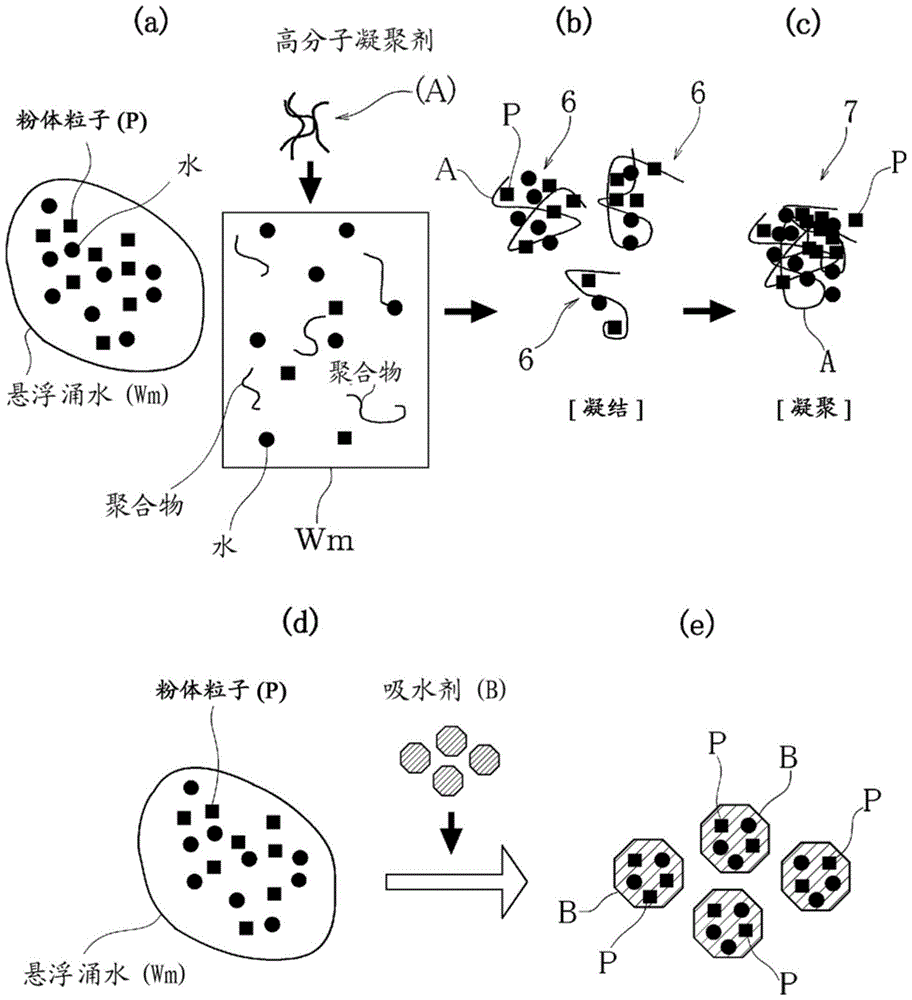

[0102] for those in Image 6 For unloading iron ore in the state shown in (a), when unloading Carajas iron ore with a moisture content of 7.9% by mass to 24.7% by mass from a transport ship, an acrylamide-based polymer coagulant is added , the amount added is such that the concentration of the chemical solution reaches 0.6% by mass relative to the amount of suspended water gushing. The amount of polymer coagulant that should be added is determined by the following method: Since the suspended water inrush Wm is generated after grabbing with a grab bucket, the amount of polymer coagulant relative to the amount of the suspended water inrush Wm is estimated from the capacity of the grab bucket , so as to determine the amount of po...

Embodiment 2

[0107] will be at Image 6 (a) When Carajas iron ore, an example of the bulk material 2 in the state shown, is unloaded from the cabin 1 of the transport ship, polyacrylate resin particles as a polymer water-absorbing agent are added instead of polymer agglomeration in Example 1 agent, and its addition amount is 1.0-2.0% by mass relative to the amount of suspended water gushing.

[0108] The amount of the polymer water-absorbing agent to be added is determined by the following method: Since the suspended water gushing Wm is generated in the depression 4 after being grabbed by the grab bucket, the capacity of the grab bucket 5 is used to estimate the amount of the polymer water-absorbing agent relative to the suspended water gushing amount. to determine the amount of polymer water-absorbing agent that should be added. Similarly, the judgment that the weight ratio of the bulk material expressed by the weight ratio to the weight ratio of the suspended gushing water is 7 or more ...

Embodiment 3

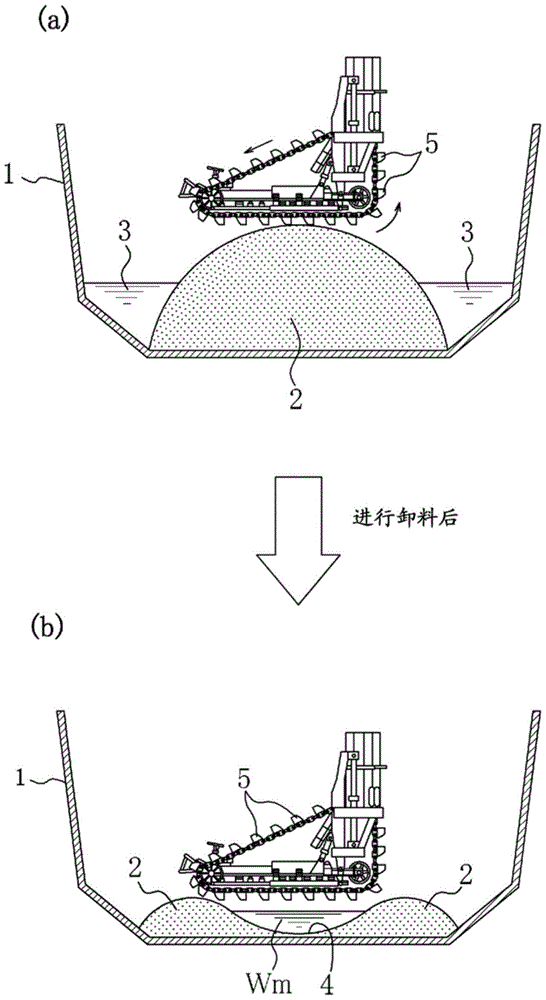

[0115] In the following, we will continue to use a continuous unloader to unload iron ore with excessive water content during a heavy rain as an example.

[0116] Even in heavy rain, continue to use such as Figure 7 The bucket of the continuous unloading machine shown is unloading. As the unloading operation progresses, when the second half of unloading reaches the stage of the lower part, the iron ore is in the stage where high moisture caused by heavy rain is beginning to be observed. caused by flooding Figure 8 In the state shown in (a), when the iron ore is unloaded from the transport ship, polyacrylate resin particles are added as a polymeric water absorbing agent, and the addition amount is 1.0 to 2.0% by mass relative to the suspended water inflow.

[0117] The amount of polymer water-absorbing agent that should be added is determined by the following method: Since the suspended water gushing Wm is generated in the depression after digging with a bucket, it is estima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com