Low-yield-ratio high-strength cold-rolled steel sheet and method for manufacturing same

A low-yield ratio, cold-rolled steel plate technology, used in manufacturing tools, metal rolling, furnaces, etc., can solve the problems of interface cracks and poor stretch-flange properties of TRIP steel plates, and achieve excellent stretch-flange properties and elongation. excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

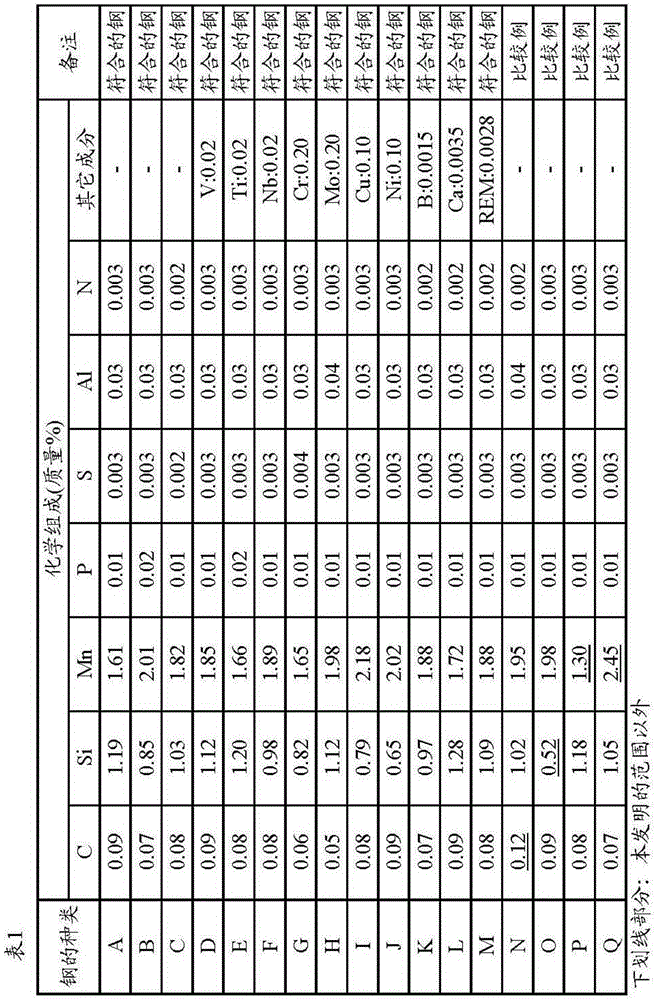

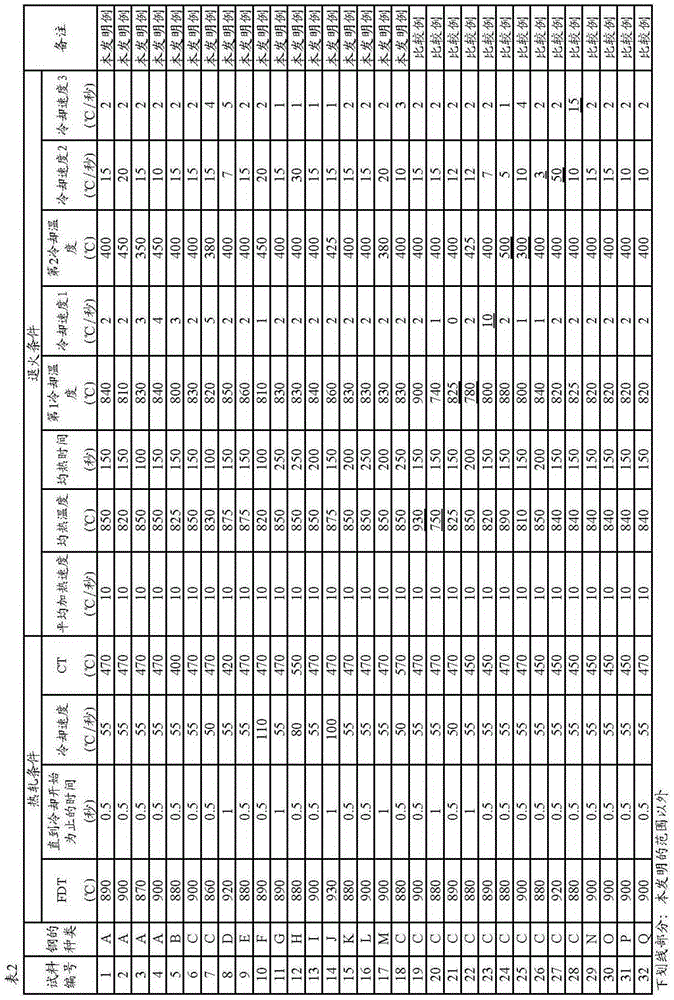

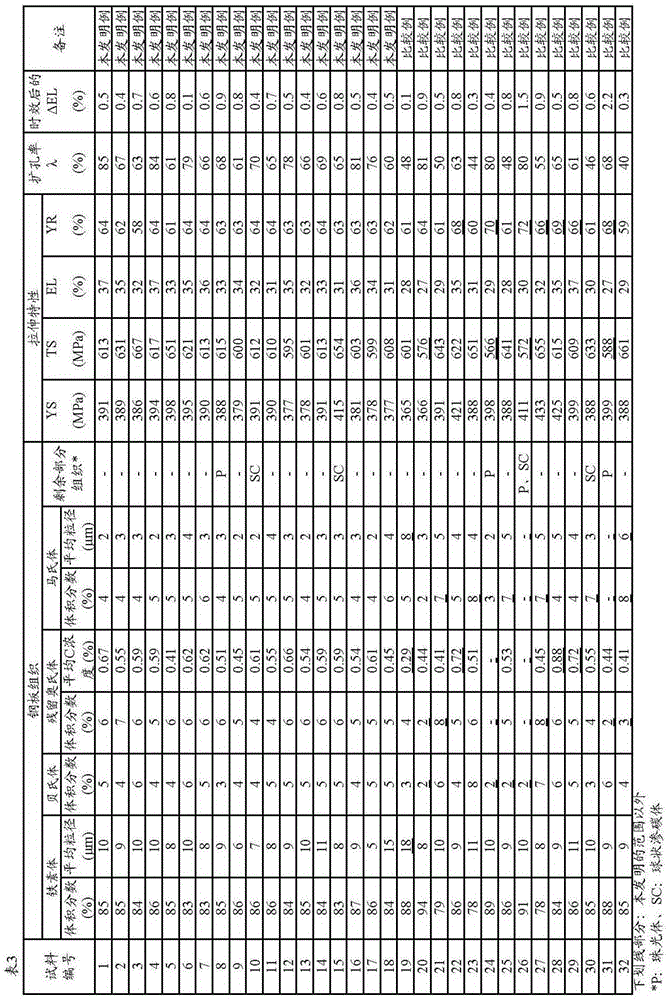

[0143] Steels having the chemical compositions shown in Table 1 were melted and cast to produce billets with a thickness of 230 mm. Next, the steel slab was heated, and the steel slab temperature was set to 1200° C., and the finish rolling temperature (FDT) was set to the temperature shown in Table 2 for hot rolling. Time and the average cooling rate (cooling rate) were used for cooling, and after the plate thickness was adjusted to 3.2 mm, coiling was performed at the coiling temperature (CT) shown in Table 2 to obtain a hot-rolled steel sheet. Next, the obtained hot-rolled steel sheet was pickled, and then cold-rolled to manufacture a cold-rolled sheet (sheet thickness: 1.4 mm). Then, heat at the average heating rate shown in Table 2, anneal with the soaking temperature and soaking time shown in Table 2, and cool to the first average cooling rate (cooling rate 1) shown in Table 2 after annealing. 1 cooling temperature, cooled to the second cooling temperature shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com