Die supply device

A technology for supplying devices and bare chips, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problem of adsorption of qualified bare chips, and achieve the effect of simplifying calculation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, an example which actualizes the embodiment for carrying out the present invention will be described.

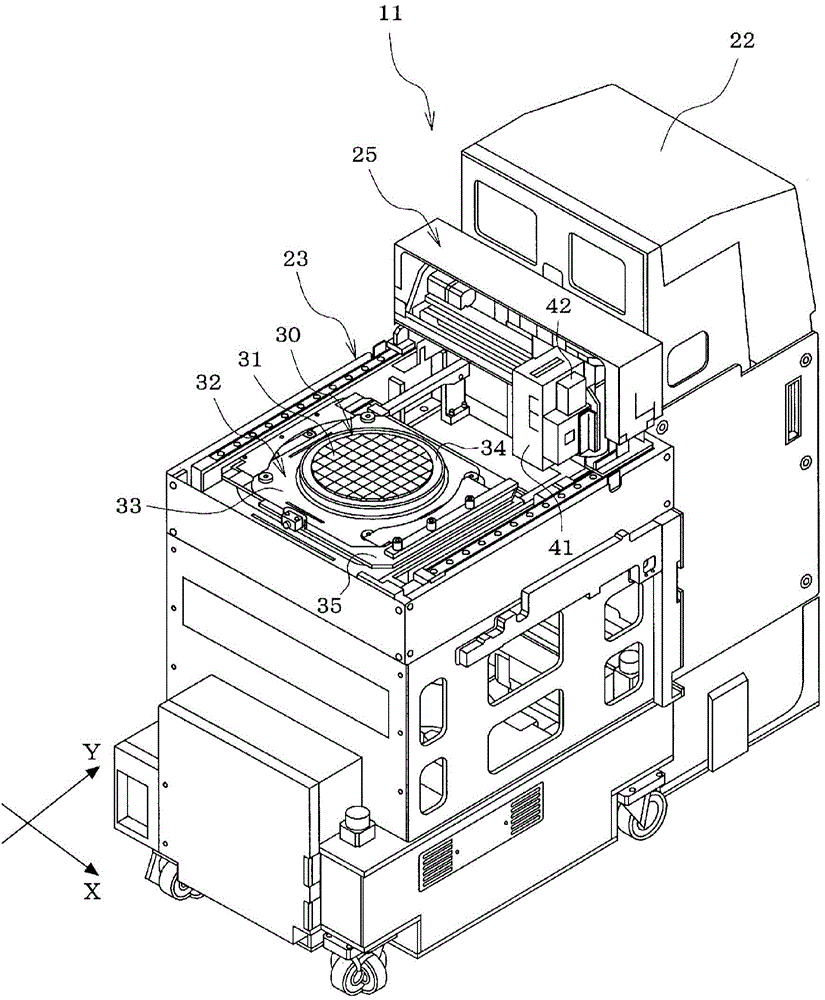

[0024] First, use figure 1 , the structure of the die supply device 11 is schematically described.

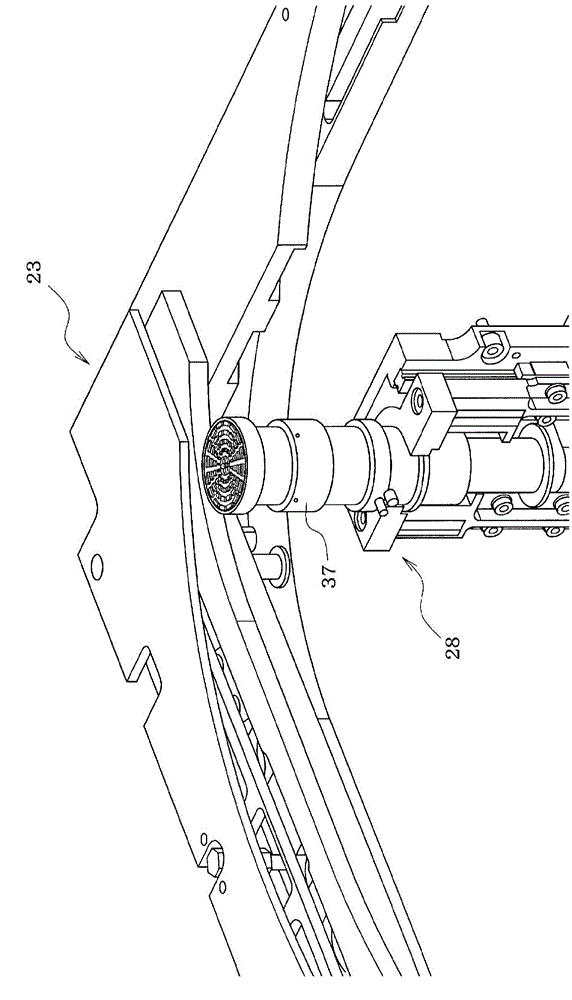

[0025] The die supply device 11 is provided with a magazine holding unit 22 (tray tower), a tray pull-out table 23, an XY moving mechanism 25, and a jacking unit 28 (refer to figure 2 ), etc., and set the tray pull-out table 23 in a state inserted into a component mounting machine (not shown).

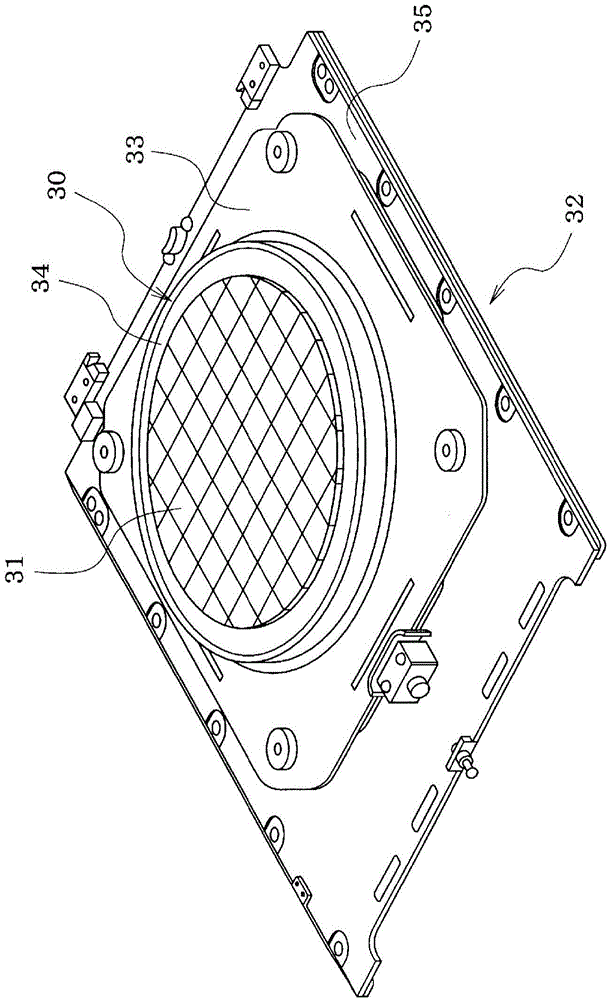

[0026] In the magazine (not shown) accommodated in the magazine holding part 22 of the die supply device 11 in a manner capable of moving up and down, the wafer tray 32 on which the wafer spreader 30 is mounted is loaded in multiple layers, and the wafer tray 32 is loaded in multiple layers during production. The magazine pulls the wafer tray 32 out onto the tray pullout station 23 . Such as image 3As shown, the wafer stretching body 30 is installed on a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com