Bread making machine

A technology of bread machine and rolling noodle belt, which is applied in the fields of dough processing, baking, food science, etc. It can solve the problems of low success rate, slow speed, and poor adaptation of dough sheets, and achieve yield and efficiency High, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

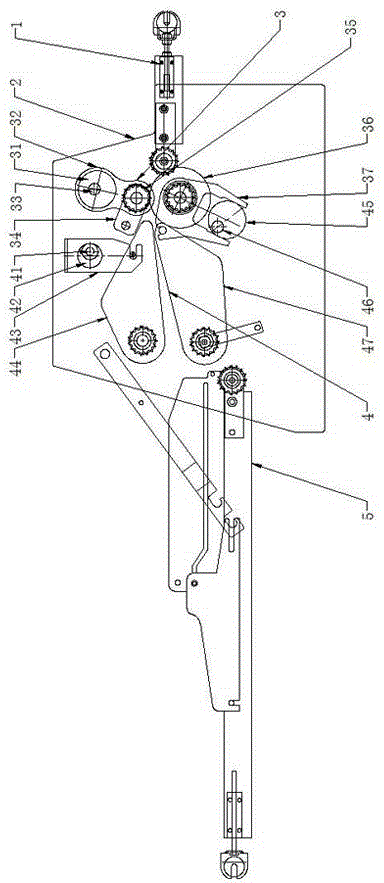

[0010] Reference figure 1 , This specific embodiment adopts the following technical solutions: it is composed of the inward conveyor frame 1, the wallboard 2, the pre-pressing roller assembly 3, the rolling noodle belt assembly 4 and the finished product conveyor frame 5. The inward conveyor frame 1 and the wallboard 2 The wallboard 2 is provided with a pre-pressing roller assembly 3 and a rolling noodle belt assembly 4, and the wallboard 2 is connected with the finished product conveying frame 5.

[0011] The pre-pressure roller assembly 3 includes an eccentric disc 31, an eccentric disc connecting sleeve 32, an upper pressure roller adjusting shaft 33, an upper pressure roller connecting rod 34, an upper pre-pressure roller 35, a lower pre-pressure roller 36, and a shift fork 37. An eccentric disk connecting sleeve 32 is provided on the outside of the disk 31, and an upper pressure roller adjustment shaft 33 is provided in the middle. The eccentric disk 31 is connected to the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com