Color-changing fire prevention fabric

A fire-resistant fabric and color-changing technology, applied in protective clothing, synthetic resin layered products, clothing, etc., can solve the problems that the color or pattern cannot be changed, the process is complicated, and the air permeability is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

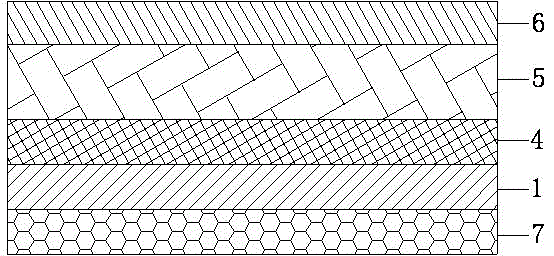

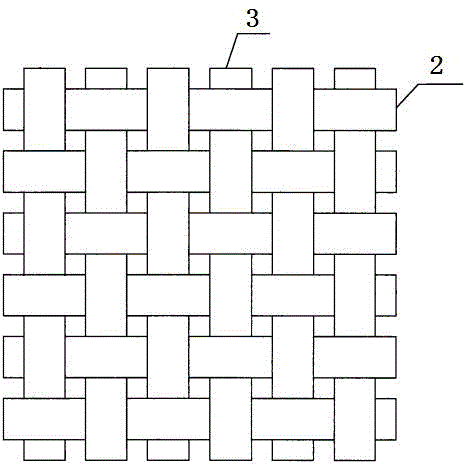

[0020] see figure 1 and figure 2 , the present invention relates to a color-changing fireproof fabric, which includes a fabric body 1, the fabric body 1 is interwoven with warp threads 2 and weft threads 3 to form a grid-like structure, and the grid-like structure makes the fabric body 1 have good air permeability and Layering, the weft 3 is made of memory fiber polyester, which makes the fabric body 1 have an excellent anti-wrinkle function and good resilience performance, and the front of the fabric body 1 is covered with a flax fiber core layer 3. The flax fiber core layer 3 has the characteristics of moisture absorption and heat dissipation, health care and bacteriostasis, antifouling and antistatic, anti-ultraviolet radiation, and high flame retardancy. The surface of the flax fiber core layer 3 is covered with a ramie fiber layer 4, and the ramie fiber layer 4 It has the characteristics of antibacterial and antibacterial, deodorant adsorption, moisture absorption and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com