Mouse cage stirring machine

A mixer and mixing mechanism technology, applied in mixers, mixers with rotating containers, dissolving, etc., can solve problems such as easy storage of materials in the mixer, incomplete storage and feeding of the mixer, and unsealed shaft ends of the main shaft , to achieve the effect of solving uneven mixing, easy maintenance and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

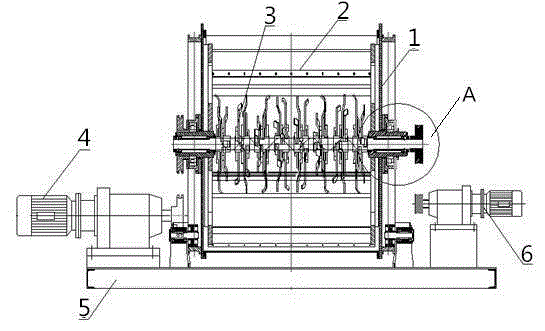

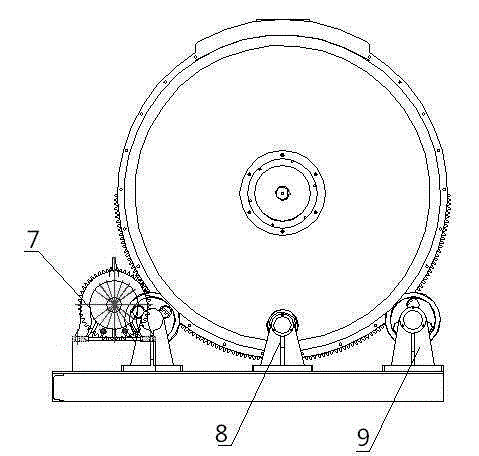

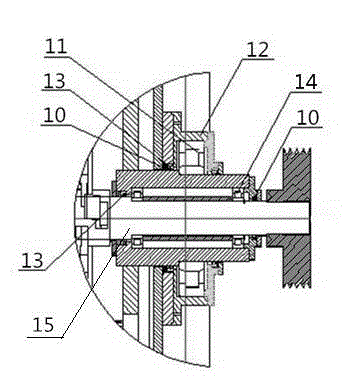

[0020] Such as Figure 1~3 As shown, the squirrel cage mixer includes a shell 1, a stirring mechanism 2, a crushing mechanism 3, a mixer motor 4, an underframe 5, a crushing mechanism motor 6, a turning mechanism 7, a shell pressing wheel 8, a shell supporting wheel 9, and a skeleton oil seal 10. The first bearing 11 , the bearing seat 12 , the high molecular polyethylene ring 13 and the second bearing 14 .

[0021] Such as figure 1 As shown, the crushing mechanism 3 includes a crushing knife and a drive shaft 15, and the crushing knife is arranged in a spiral manner on the drive shaft 15, wherein the crushing knife is divided into a long knife and a short knife, and the crushing knife is fixed on the knife rest by bolts, and the knife rest Fixed on the drive shaft 15, the drive shaft 15 is connected with the crushing mechanism motor 6, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com