Vacuum Drum System In A Printing Material Sheet Processing Machine And Drying Unit

A technology of vacuum drum and printing materials, which is applied in printing presses, rotary printing machines, general parts of printing machinery, etc., can solve the problem that the vacuum drum system is not suitable, and achieve the effect of smooth disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

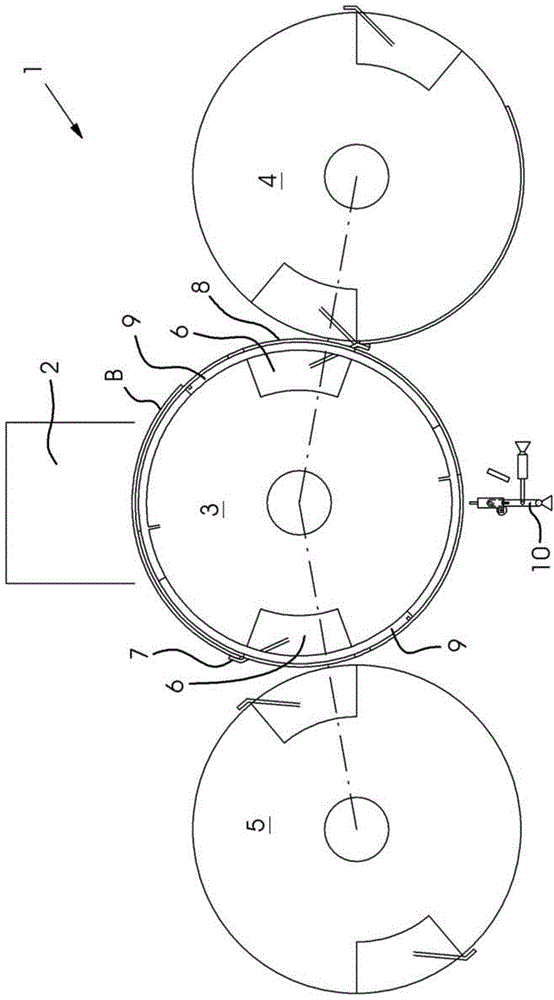

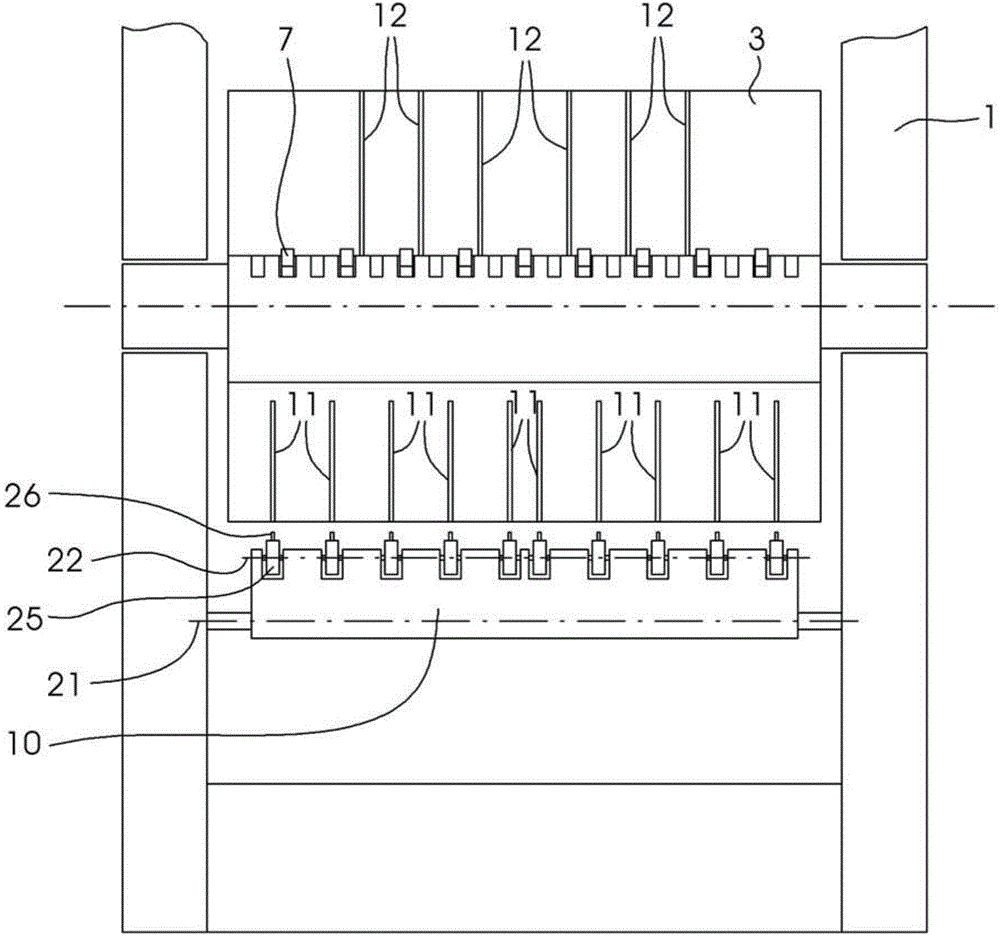

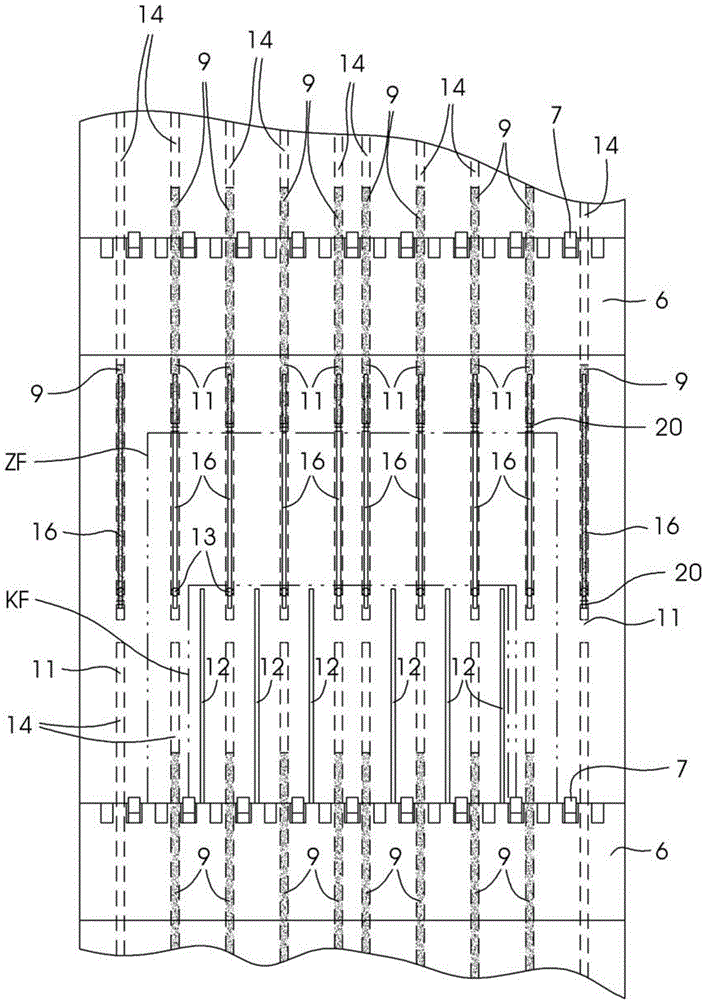

[0026] Figure 1-7 is a schematic view in which, for greater clarity, the sectioned components are shown in unshaded manner. in the attached Figure 1-7 In , the parts corresponding to each other are marked with the same reference numerals.

[0027] figure 1 A printing press 1 is shown in section, which is used for printing sheets B by offset lithography. The special equipment 2 of the printing press 1 is shown, which is arranged in series with the offset printing tools of the printing press 1 which are not shown in the figure. The special device 2 has a vacuum drum 3 which, during the transport of the sheets B, receives the sheets B from a feed roller 4 and transfers them to a feed roller 5 . This vacuum drum 3 can also be referred to as a vacuum drum system. The vacuum drum 3 has radial drum channels 6 in which clamping grips 7 are respectively arranged for holding a sheet B at its leading edge. see Figure 4 , if the special equipment 2 is an inert gas drying equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com