floor cleaner

A floor cleaning machine and frame technology, which is applied in cleaning machinery, floor cleaning, cleaning equipment, etc., can solve the problems of blocked floor washing width of the floor washing machine, limited suction of the suction pump, and low floor cleanliness, etc., and achieves low production cost , Sewage recycling easily, clean floor clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

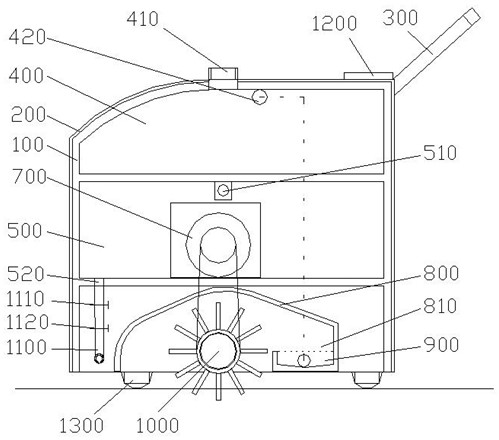

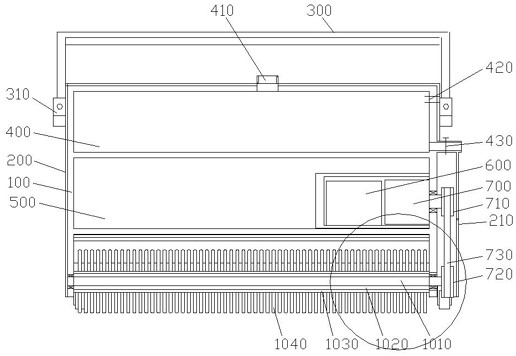

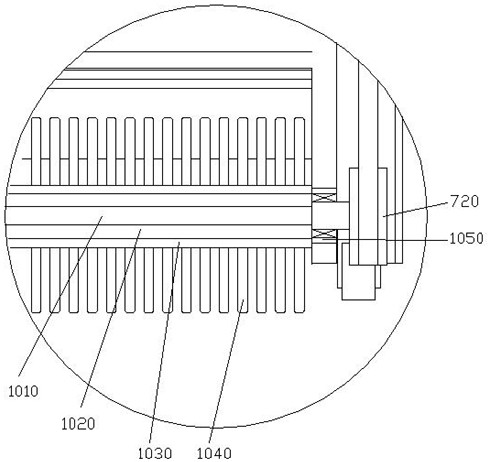

[0030] As shown in the drawings, the present invention includes a frame 100, a casing 200, a handrail 300, a sewage tank 400, a clean water tank 500, a storage battery 600, a motor 700, a water collecting cover 800, a micro pump 900, a drum 1000, a drip pipe 1100 and an instrument control panel 1200,

[0031] A set of universal wheels 1300 are arranged at the bottom of the frame 100, the casing 200 is covered on the frame 100, steel sleeves 310 are respectively provided on both sides of the frame 100, and the handrails 300 are plugged into the steel sleeves 310 and fastened by screws;

[0032] Sewage tank 400, clean water tank 500, water collecting cover 800 and roller 1000 are installed on the frame 100 sequentially from top to bottom, the top of the sewage tank 400 is provided with a sewage tank water injection port 410, and one side of the clean water tank 500 is provided with a clean water tank injection port. The water outlet 510, the bottom of the clean water tank 500 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com