Ship seagoing capability testing system

A testing system and ship technology, applied in ship parts, ship construction, ships, etc., can solve problems such as not reflecting real motion, spring elastic damping, affecting vibration frequency, etc., achieving accurate positioning, reduced range, and ultra-low damping coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

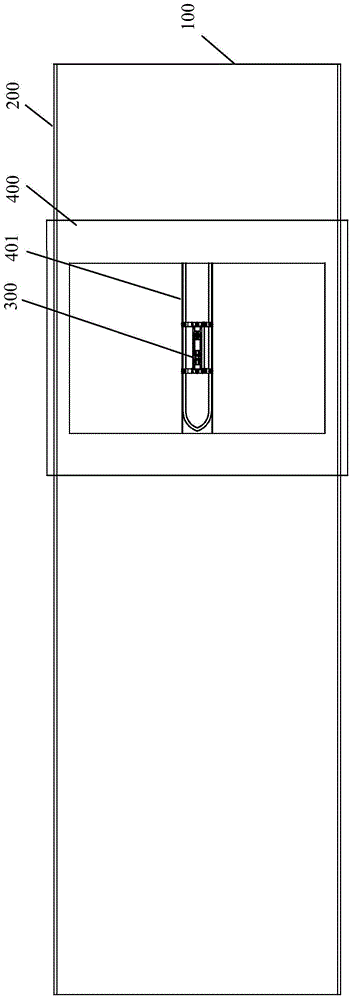

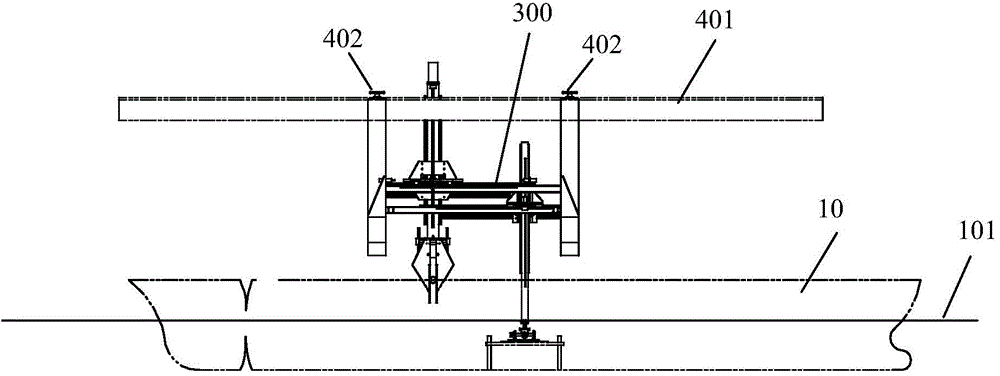

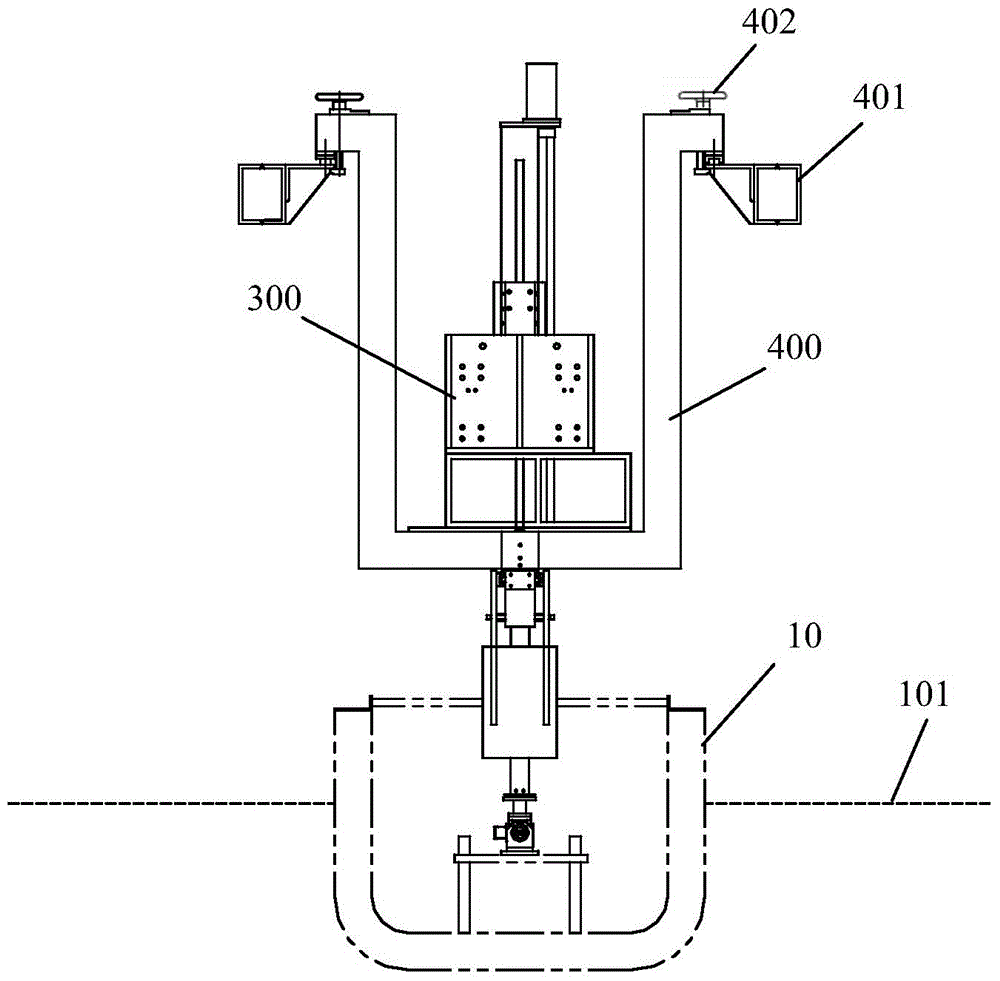

[0038] Such as Figure 1 to Figure 3 As shown, the ship airworthiness test system of the present invention includes a pool 100, main rails 200 located on both sides of the pool, a trailer 400 located on the main rail 200, and a ship airworthiness tester 300 installed on the trailer 400. The trailer 400 is used to tow the ship seaworthiness tester 300 to move along the main track 200 .

[0039] During the test, the ship model 10 is connected under the ship seaworthiness tester 300 , dragged by the trailer 400 , and the ship model 10 is driven by the ship seaworthiness tester 300 to sail on the simulated water surface 101 with waves in the pool 100 .

[0040] In order to adjust the position of the ship seaworthiness tester 300 on the trailer 400 conveniently, so as to adapt to connecting different types of ship models, the trailer 400 also has a trailer track 401 . After the ship seaworthiness tester 300 is adjusted on the trailer track 401 , it is locked with the locking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com