Grouting trolley

A grouting trolley and trolley technology, applied in the field of grouting trolleys and grouting equipment, can solve problems such as inaccurate measurement of cement slurry flow, damage to the internal structure of the pressure gauge, and affect the quality of prestressed bridges, etc., to increase the service life , prolong the service life and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with embodiments:

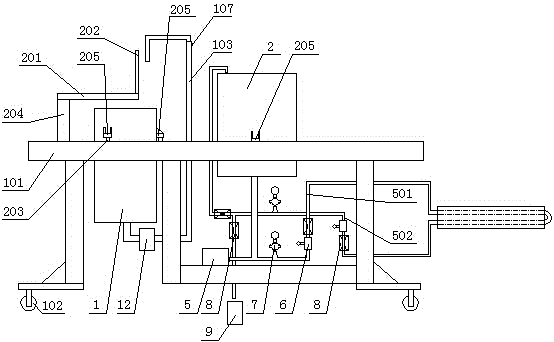

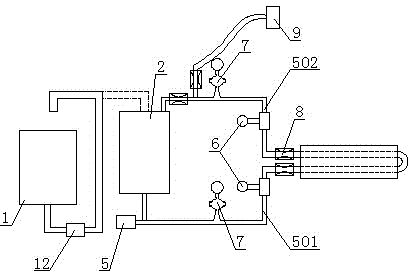

[0035] Such as figure 1 As shown, the present invention includes a base 101, the lower end of the base 101 is provided with a pulley 102 that facilitates the movement of the base, and the mixing tank 1 and the slurry tank 2 are fixed on the base 101.

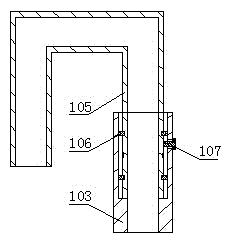

[0036] The base 101 is a frame welded by back-shaped steel. The outer circumferences of the mixing tank 1 and the slurry tank 2 are provided with fixing ears 205. The slurry tank 2 is placed on the back-shaped steel of the base 101 through the fixing ears 205 and tightened by bolts. A solid connection; a gravity sensor 203 is provided between the fixing ear 205 on the mixing tank 1 and the back-shaped steel of the base 101, and the gravity sensor 203 is connected to the control center. The number of gravity sensors is 3, and they are evenly distributed on the outer circumference of the mixing tank 1, which can accurately detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com