Supporting roll bearing base

A technology for bearing housings and support rollers, applied in the direction of bearing components, shafts and bearings, and rigid supports for bearing components, can solve the problems of peak load concentration and shortened service life of bearings, and achieve reduced broken belts, extended bearing life, and reduced The effect of small use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

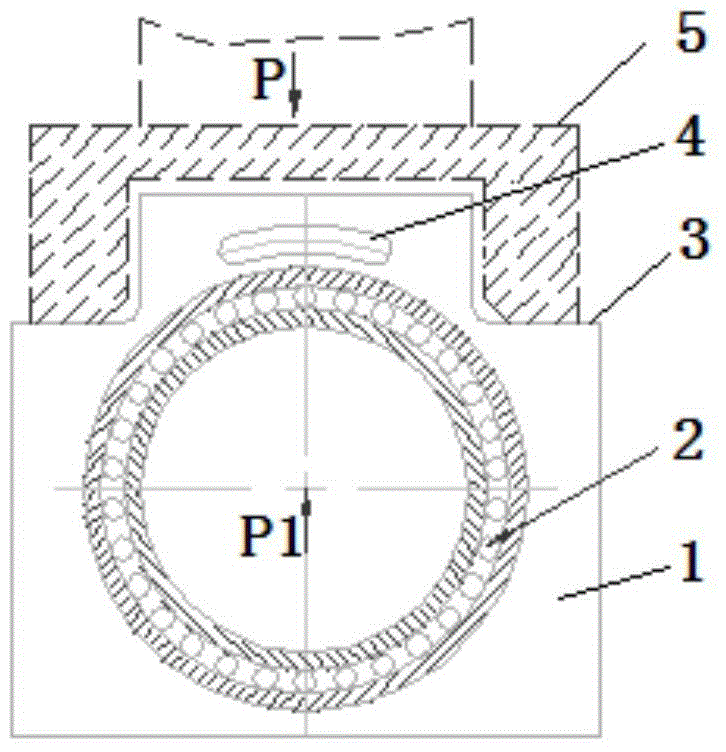

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

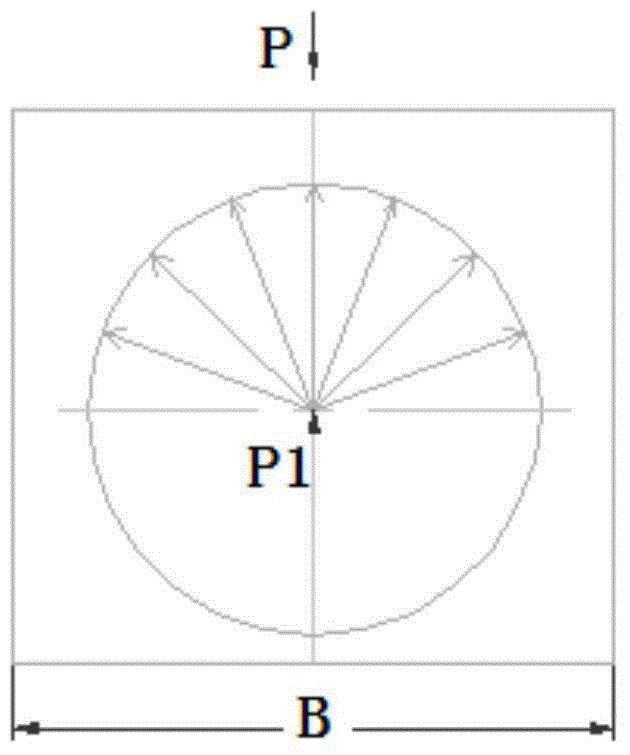

[0018] refer to figure 1 , the structure of the prior art rolling mill backup roll chock is that a through hole is opened in the chock, the bearing is installed in the hole, the circular hole in the middle is used for installing the bearing, the chock (horizontal) width is B, and P is The pressing force acts on the middle of the bearing seat, and the direction is from top to bottom; P1 is the rolling force borne by the bearing.

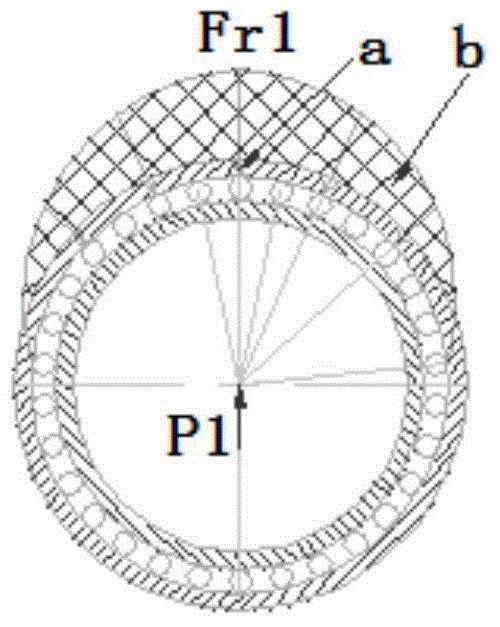

[0019] refer to figure 2 , is the structural force diagram of the existing bearing seat, the force distribution of the rolling elements inside the bearing is, b in the figure is the force distribution curve of other rolling elements, and a in the figure is the position of the single rolling element with the largest force, The maximum force Fr1=0.146P, it can be seen that the pressing force P concentrates on the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com