A gas damping hydraulic pipeline vibration damping pipe clamp

A hydraulic pipeline and gas damping technology, which is applied in the direction of pipes/pipe joints/fittings, pipe supports, vibration suppression adjustment, etc., can solve problems such as collision and friction between pipelines and pipe clamps, loose pipe clamps, and pipeline surface wear , to achieve the effect of reducing the loosening of fixing bolts, prolonging the service life and avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

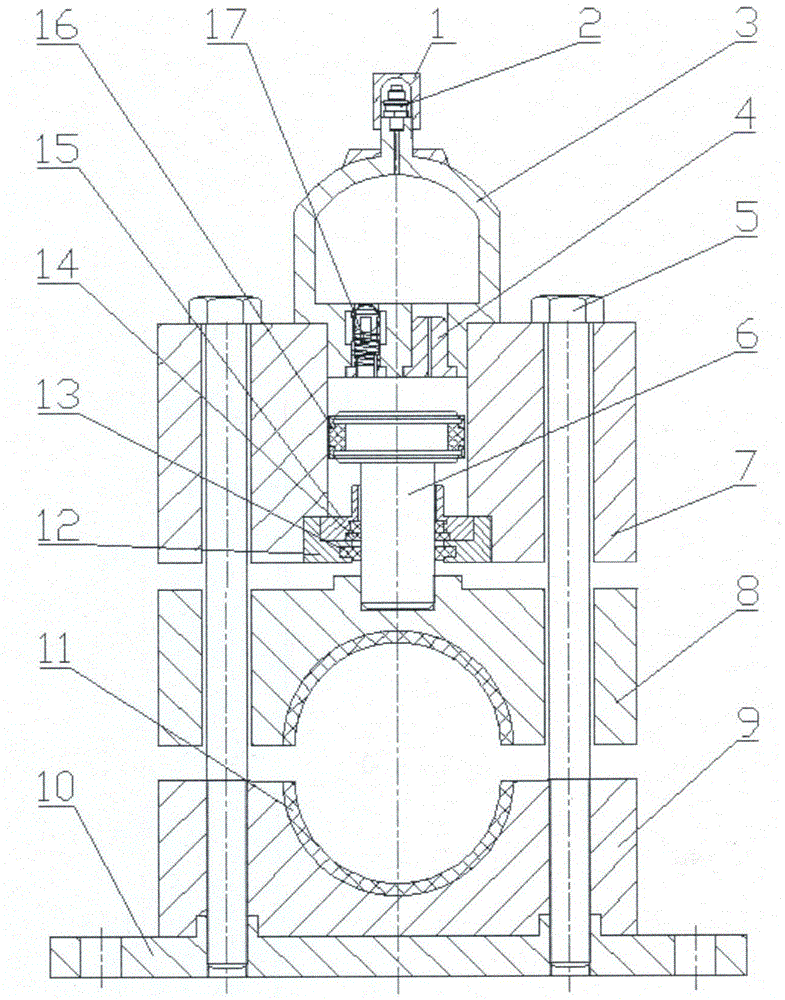

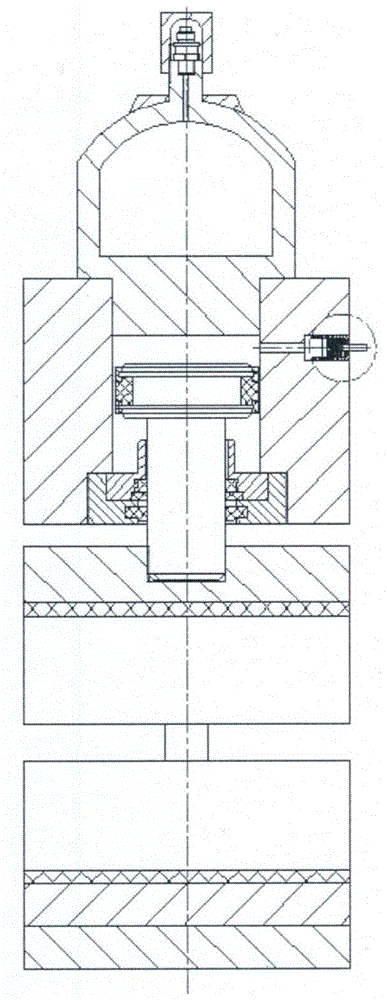

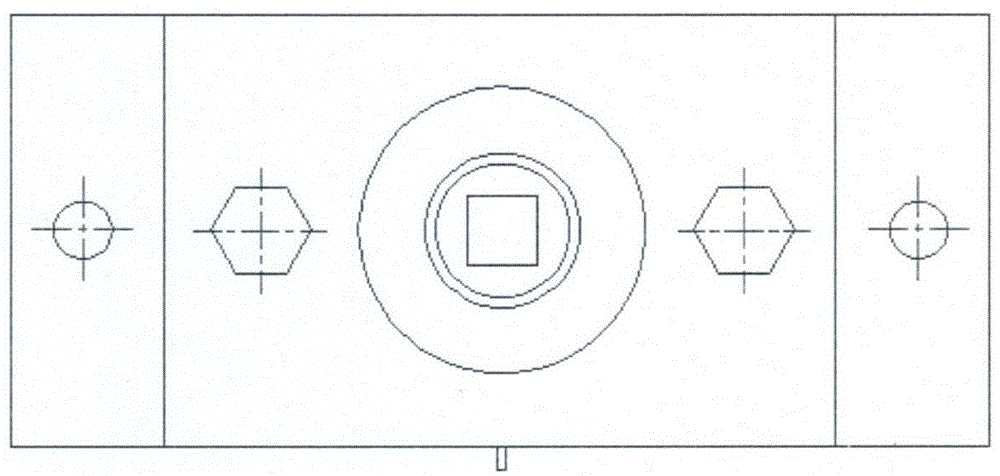

[0014] The present invention will be further described below in conjunction with accompanying drawing:

[0015] exist figure 1 , figure 2 and image 3 In the schematic diagram of a gas damping hydraulic pipeline damping pipe clamp shown, there are through holes for fasteners on the lower cover plate 10 of the pipe clamp, and two identical holes are arranged inside the through hole of the lower cover plate of the pipe clamp screw holes, and the upper opening of each screw hole is provided with a boss for positioning. A lower pipe clamp 9 is arranged on the lower cover plate of the pipe clamp. The lower pipe clamp is provided with a semi-cylindrical groove with an upward opening on the upper part of the cuboid base body. noodle. A damping material layer 11 corresponding to the radius of curvature is arranged in the semi-cylindrical groove of the lower pipe clip. There are two vertical screw holes on both sides of the semi-cylindrical groove of the lower pipe clamp. The ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com