Low-pass filtering based engine fuel consumption detection system

A low-pass filter processing and fuel consumption technology, applied in the direction of measuring devices, relative volume flow measurement, liquid/fluid solid measurement, etc., can solve the problem of low test accuracy, achieve high signal fidelity, rapid response, and improve accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

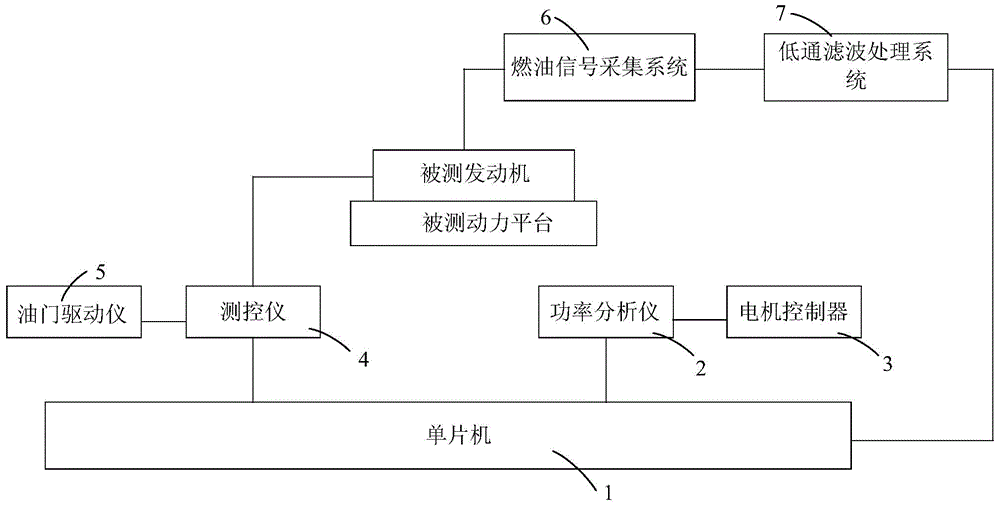

[0022] Such as figure 1 As shown, the present invention includes a tested power platform and a tested engine fixed on the tested power platform. In order to detect the fuel consumption of the engine under test, the present invention also includes a single-chip microcomputer 1, a measuring and controlling instrument 4 and a power analyzer 2 connected with the single-chip microcomputer 1, a throttle driver 5 connected with the measuring and controlling instrument 4, and a power analyzer 2 A connected motor controller 3, a fuel signal acquisition system 6 connected to the engine under test, and a low-pass filter processing system 7 connected to the fuel signal acquisition system 6; the low-pass filter processing system 7 communicates with the The single-chip microcomputer 1 is connected, and the measuring and controlling instrument 4 is also connected with the engine under test.

[0023] Wherein, the single-chip microcomputer 1 is used as the control system of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com