Heavy automobile rain test system and process

A technology for rain test and heavy-duty vehicles, which is used in liquid/vacuum measurement for liquid tightness, etc. It can solve the problems of low efficiency, high energy consumption, and large production land area to ensure product quality and improve work efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

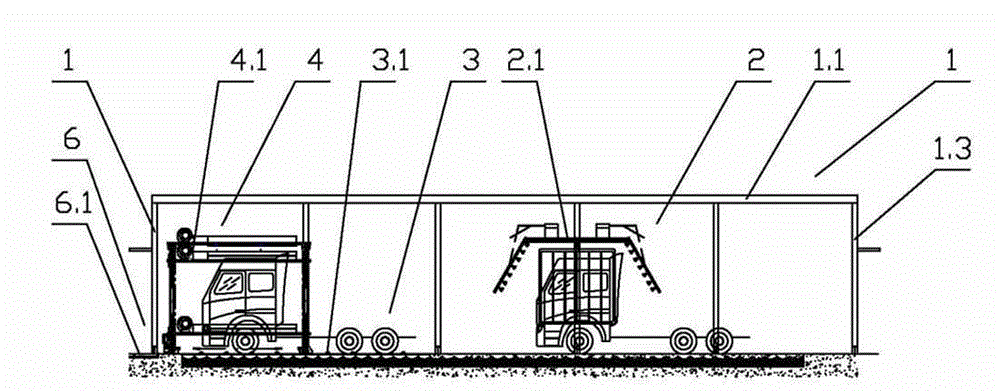

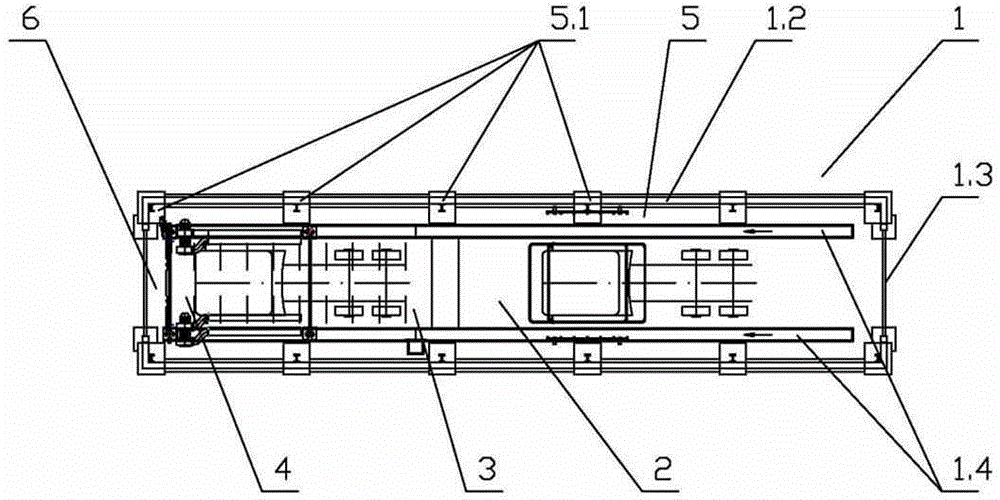

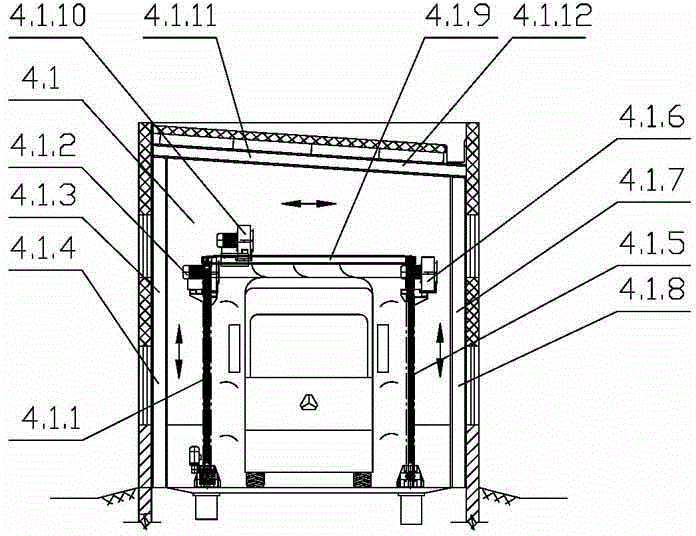

[0037] Such as Figure 1-Figure 5 As shown, the heavy-duty vehicle rain test system includes a rain test room 1, a rain area 2 located in the rain test room 1, and a bump zone area 3 and a blowing area are also provided in the rain test room 1. 4 and the heating area 5, a floor heating area 6 is provided at the exit of the rain test room 1; the rain area 2, the bump zone area 3 and the blowing area 4 are arranged sequentially from the entrance to the exit of the rain test room 1, so The above-mentioned heating area 5 is located on the inside of the wall of the rain test room 1;

[0038] The rain-drenching area 2 includes the rain-drenching equipment 2.1 which adopts PLC control, can realize the automatic rain-drenching function, ensures the reliability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com