Diagnosis method for large axial vibration of bearing pedestal due to foundation loosening

A technology of axial vibration and diagnostic methods, which is applied in vibration testing, testing of mechanical components, testing of machine/structural components, etc., can solve problems affecting production, increase detection strength, etc., to avoid equipment damage, simple operation, The effect of eliminating hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

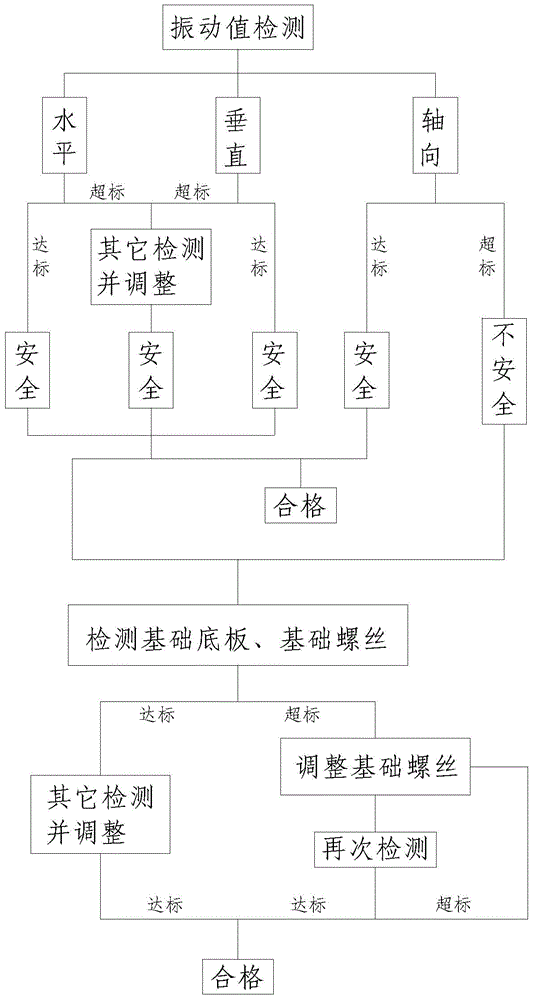

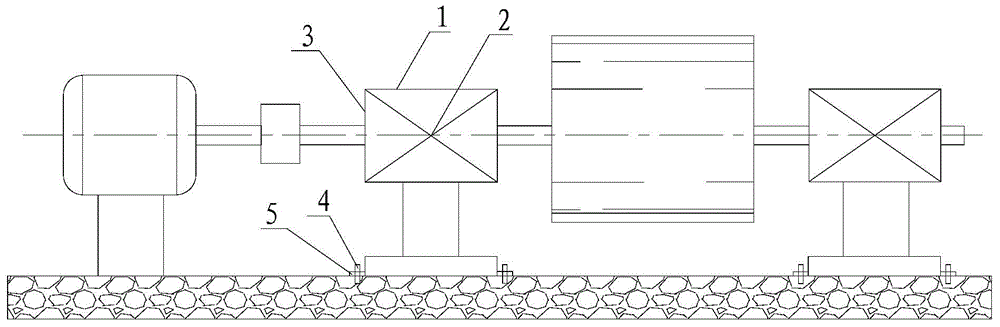

[0027] Such as figure 2 Shown is a schematic diagram of the structure of a cantilever fan. The rotor of the fan is supported by two bearing seats. The bearing seat close to the motor is the load end bearing seat, and the one far away from the motor is the non-load end bearing seat. When it is necessary to detect the bearing seat at the load end, place the vibration sensor on the top 1, the horizontal position 2 and the axial side 3 of the bearing seat in sequence, measure three sets of data at each position, and then obtain the average value. Then compare the vibration values at the three positions with the standard values. If it is found that the vibration values at the top 1 and horizontal position 2 are less than 4.5mm / s, and the vibration value at the axial side 3 is greater than or equal to 7.1mm / s, turn to If the frequency is dominant, it can be judged that the axial vibration is too large, and then the base plate 5 and the base screw 4 are tested. First move the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com