Light guide and lighting device using the light guide

A light guide and lighting technology, applied in the light guide, light guide, optics and other directions of the lighting system, can solve the problems of uneven display and uneven light, and achieve the effect of improving the shading rate and reducing the uneven light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0061] The light guide 100 of the first embodiment will be described below.

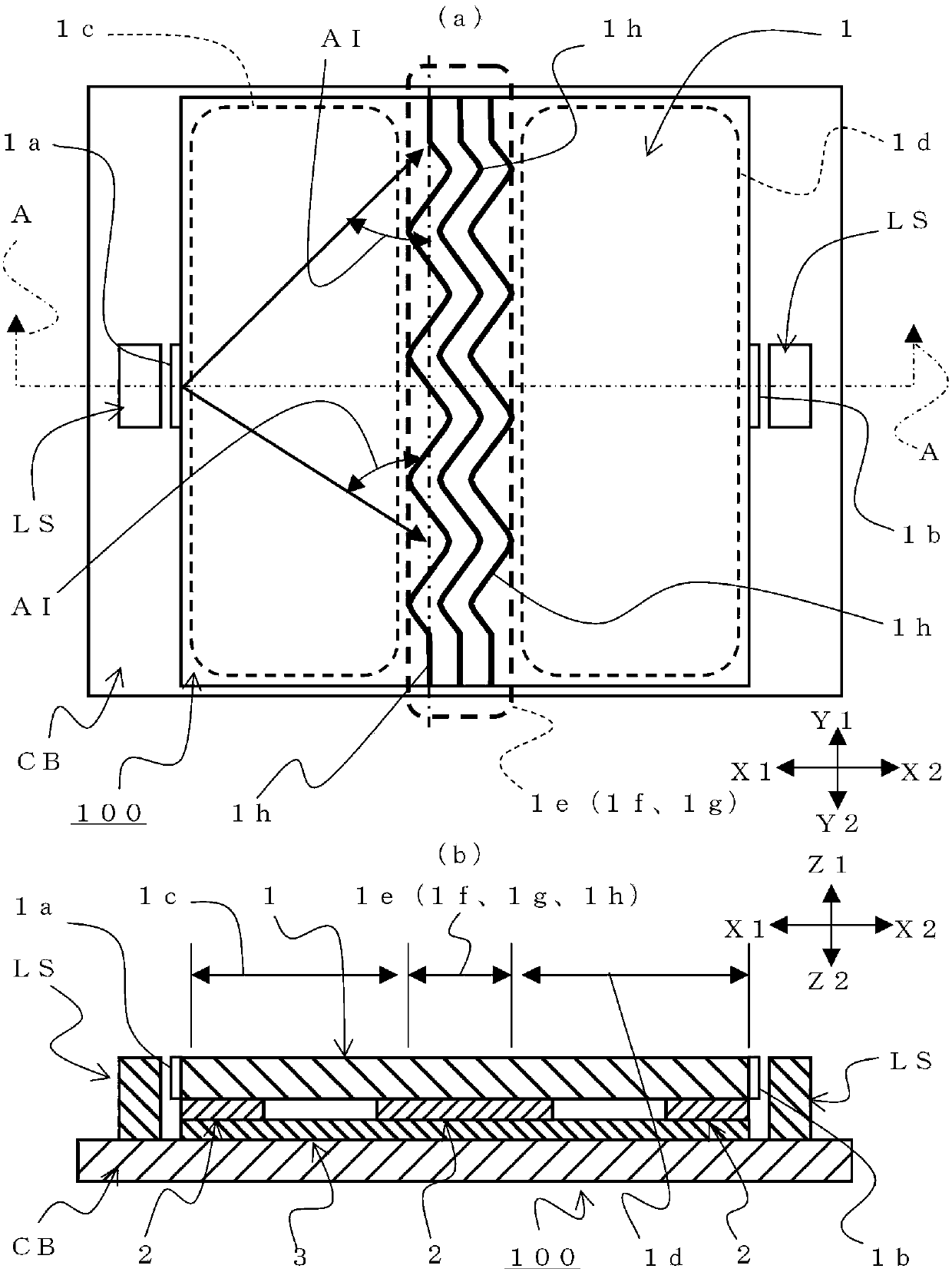

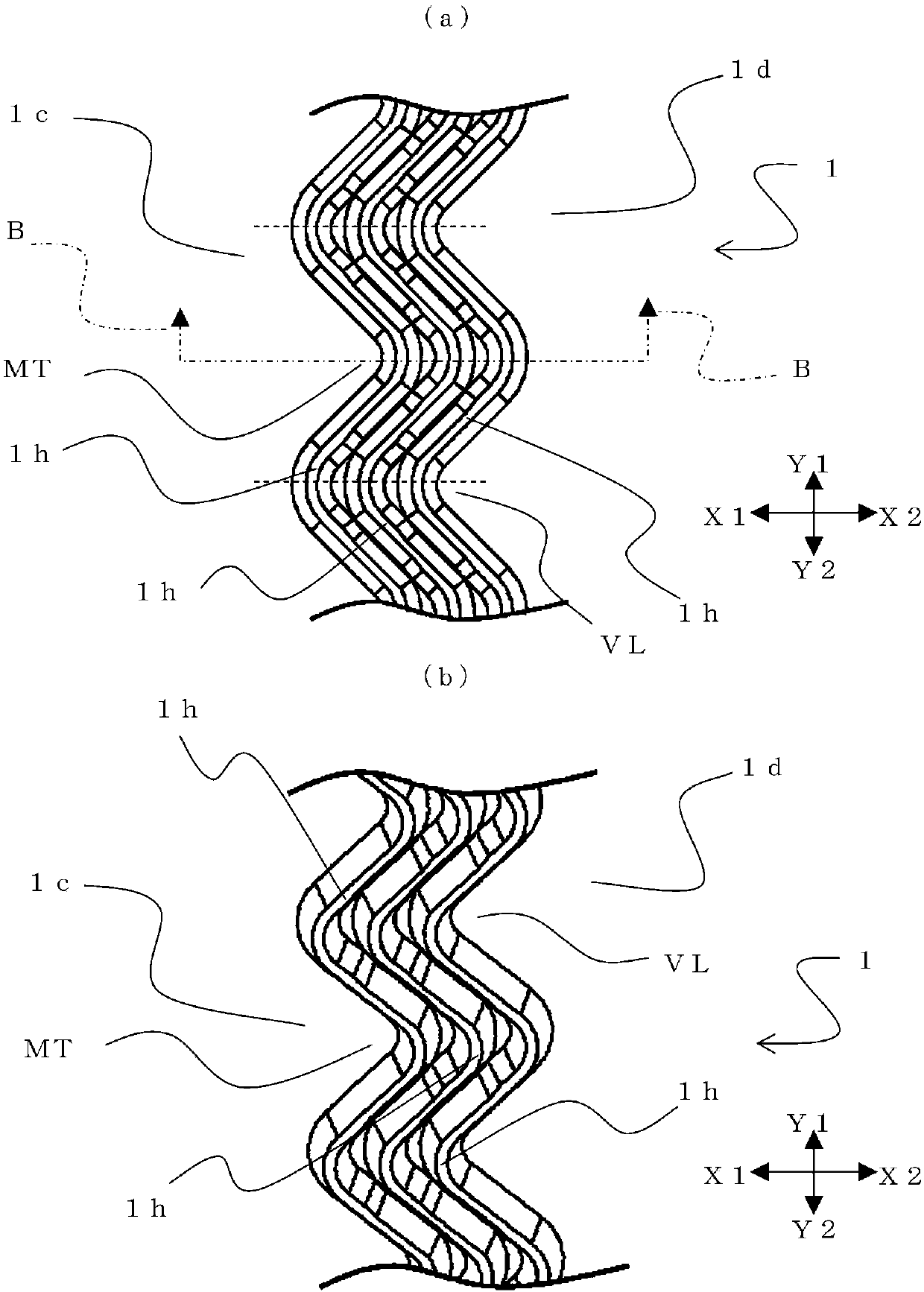

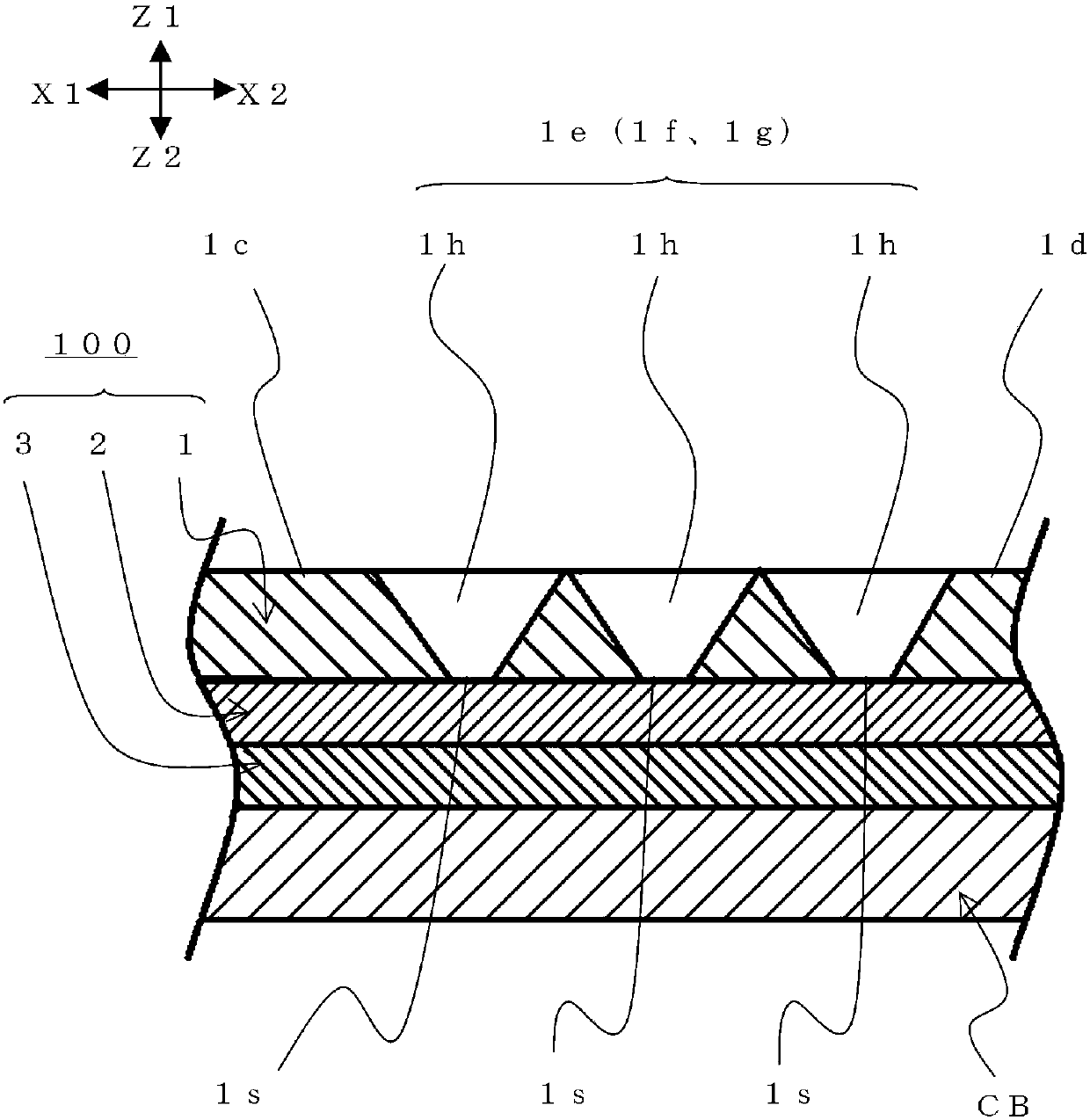

[0062] First, use Figure 1 to Figure 3 The structure of the light guide 100 of this embodiment will be described. figure 1 It is a figure which shows the light guide 100 of 1st Embodiment, figure 1 (a) is a schematic plan view showing the appearance of the light guide 100, figure 1 (b) is figure 1 A cross-sectional view of line AA described in (a). figure 2 It is a figure which shows the corrugated part of the 1st slit 1h in 1st Embodiment, figure 2 (a) is an enlarged plan view showing the first slit 1h, figure 2 (b) is an enlarged perspective view showing the first slit 1h. image 3 yes figure 2 A schematic cross-sectional view of line BB described in .

[0063] Such as figure 1 As shown, the light guide 100 includes a base member 1, a light shielding member 2, and a reflection member 3, and is arranged on a substrate CB together with a light source LS.

[0064] The base member 1...

no. 2 Embodiment approach

[0093] The light guide 200 of the second embodiment will be described below. In the light guide 200 of the second embodiment, the first slit region 1f of the light guide 100 of the first embodiment is different. Except for the first slit region 1f, the light guide 100 of the first embodiment is the same as the light guide 200 of the second embodiment in terms of components and structures. In the following description, parts different from those of the light guide 100 of the first embodiment will be described, and the names and symbols used in the light guide 100 of the first embodiment will be used for descriptions of common components and parts.

[0094] First, use Figure 5 to Figure 7 The structure of the light guide 200 of the second embodiment will be described. Figure 5 It is a figure which shows the light guide 200 of 2nd Embodiment, Figure 5 (a) is a schematic plan view showing the appearance of the light guide 200, Figure 5 (b) means Figure 5 Cross-sectional ...

no. 3 Embodiment approach

[0114] The light guide 300 of the third embodiment will be described below. In the light guide 300 of the third embodiment, the structure of the base member 1 of the light guide 100 of the first embodiment is different from that of the light guide 200 of the second embodiment. The light guide 100 of the first embodiment, the light guide 200 of the second embodiment, and the light guide 300 of the third embodiment have the same components and configurations except for the base member 1 . In the following description, parts different from the light guide 100 of the first embodiment and the light guide 200 of the second embodiment will be described, and the light guide 100 of the first embodiment and the light guide 200 of the second embodiment will be used for common components and parts. Names and symbols used in the light guide 200 of the embodiment will be described.

[0115] First, use Figure 9 to Figure 11 The structure of the light guide 300 of the third embodiment will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com