A kind of alcohol-resistant water-based resin emulsion binder for quick-drying ink and preparation method thereof

A water-based resin and alcohol-resistant technology, applied in the direction of ink, application, pigment slurry, etc., can solve the problems of latex particle demulsification, emulsifier easy to dissolve, unusable, etc., achieve good stability of color paste, improve drying rate, Reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

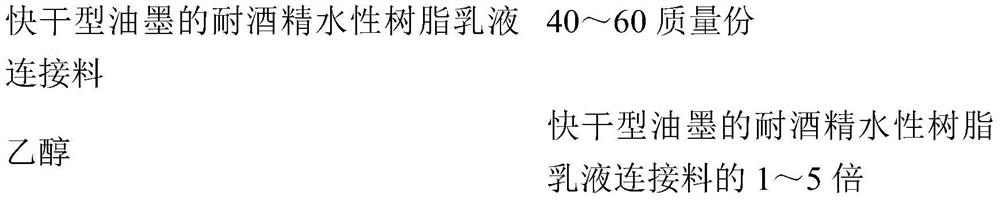

Examples

Embodiment 1

[0054] (1) Preparation of alcohol-resistant water-based acrylate emulsion resin

[0055] SMA with a molecular weight of 1000g / mol and octaalkylamine are put into the reaction bottle according to the mass ratio of 1:1.1 (the primary amine is slightly excessive to ensure complete ring opening, the same below), ethyl acetate (EA, the same below) is used as the solvent, 60°C Under the condition of reaction 2h. After cooling to room temperature, octaalkylsulfonic acid in the amount of octaalkylamine and the like was added to the reaction solution, and reacted at room temperature for 4 hours. The reaction solution was distilled off under reduced pressure to remove the EA solvent, and then dissolved in 100mL of ethanol to prepare a 1mol / L KOH ethanol solution, which was added dropwise to the ethanol solution until the pH value of the system was greater than or equal to 7. Emulsifier A is obtained.

[0056] In the disperser, add 3 parts by mass of emulsifier A, 1 part by mass of emu...

Embodiment 2

[0060] (1) Preparation of alcohol-resistant water-based acrylate emulsion resin

[0061] SMA with a molecular weight of 2000g / mol and dodecylamine were put into the reaction flask at a mass ratio of 1:1.1, EA was used as a solvent, and reacted at 80°C for 2h. After cooling to room temperature, the reaction liquid was added with dodecylamine and other substances such as propane sultone, and reacted at room temperature for 4 hours. The reaction solution was distilled off under reduced pressure to remove the EA solvent, and then dissolved in 100mL of ethanol to prepare a 1mol / L NaOH ethanol solution, which was added dropwise to the ethanol solution until the pH value of the system was greater than or equal to 7. Emulsifier A is obtained.

[0062] In the disperser, add 2 mass parts of emulsifier A, 4 mass parts of emulsifier B acrylic acid-terminated polyethylene glycol (PEG segment molecular weight is 1000g / mol), 8 mass parts of IBOMA, 50 mass parts of methyl Methyl acrylate, 1...

Embodiment 3

[0066] (1) Preparation of alcohol-resistant water-based acrylate emulsion resin

[0067] SMA with a molecular weight of 3000g / mol and dodecylamine were put into the reaction flask at a mass ratio of 1:1.1, and EA was used as a solvent, and reacted at 100°C for 2h. After cooling to room temperature, dodecylbenzenesulfonic acid and dodecylamine were added to the reaction solution, and reacted at room temperature for 4 hours. The reaction solution was distilled off under reduced pressure to remove the EA solvent, and then dissolved in 100mL of ethanol to prepare a 1mol / L NaOH ethanol solution, which was added dropwise to the ethanol solution until the pH value of the system was greater than or equal to 7. Emulsifier A is obtained.

[0068] In the disperser, add 3 mass parts of emulsifier A, 3 mass parts of emulsifier B acrylic acid-terminated polyethylene glycol (PEG segment molecular weight is 2000g / mol), 12 mass parts of IBOMA, 52 mass parts of methyl Methyl acrylate, 18 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com