Black resin composition for light-shielding film, substrate with light-shielding film having light-shielding film, color filter, and touch panel

A technology of black resin and light-shielding film, which can be used in optical filters, photosensitive materials for optomechanical equipment, optics, etc., and can solve the problems of reduced storage stability of resin compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0106] In a 500ml four-necked flask with a reflux cooler, 78.63g (0.17mol) of BPFE, 24.50g (0.34mol) of acrylic acid, 0.45g of TPP, and 114g of PGMEA were added, and the mixture was stirred for 12 hours under heating at 100 to 105°C. The reaction product is obtained.

[0107] Next, 25.01 g (0.085 mol) of BPDA and 12.93 g (0.085 mol) of THPA were added to the obtained reaction product, and the mixture was stirred under heating at 120 to 125°C for 6 hours to obtain a polymerizable unsaturated group-containing alkaline soluble resin Solution (A)-1. The solid content concentration of the obtained resin solution was 55.8 wt%, the acid value (calculated as solid content) was 103 mgKOH / g, and the Mw measured by GPC analysis was 2600.

[0108] [Preparation of resin solution: A component solution]

[0109] The resin solutions A1 to A3 containing the following (A) components were prepared. The refractive index of the cured product after the resin solutions A1 to A3 are dried / cured respectiv...

Embodiment 1

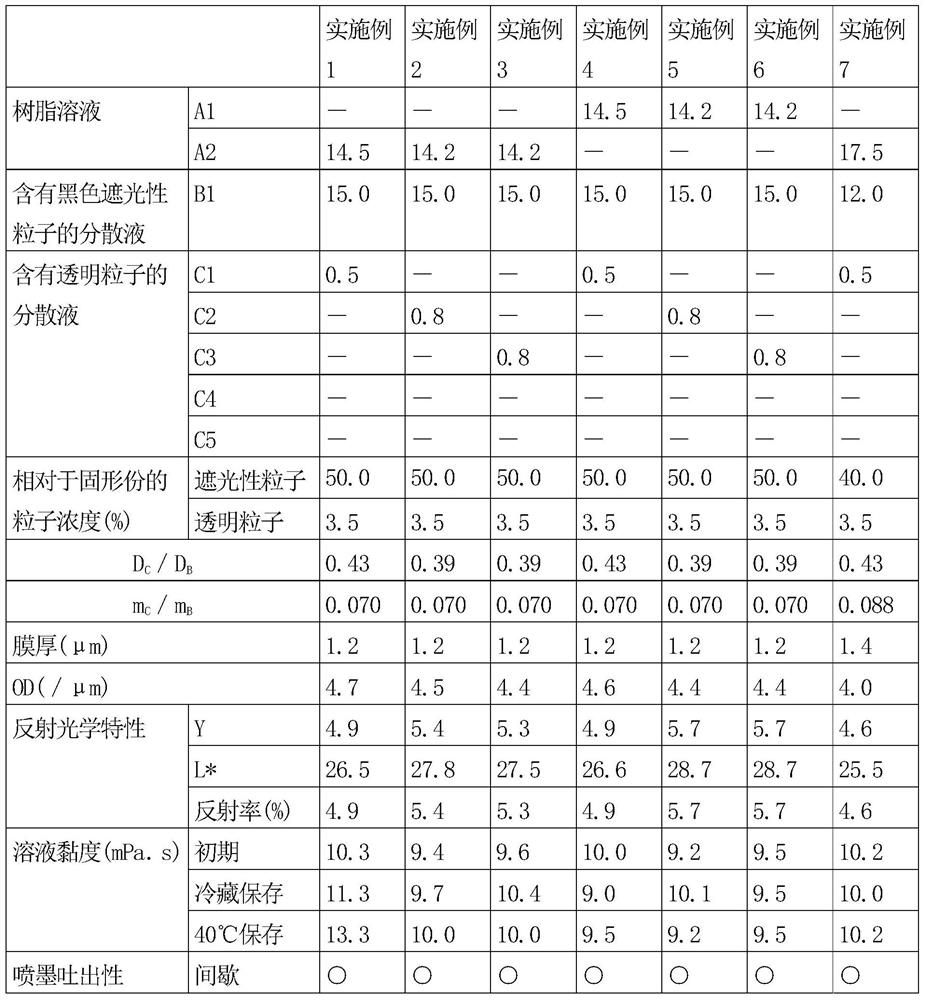

[0128] Mix 14.5 parts by mass of resin solution A2, 15 parts by mass of carbon black dispersion B1, and 0.5 parts by mass of silica dispersion C1, (30 parts by mass in total), pressurize and filter through a 1μm depth filter to prepare Black resin composition for light-shielding film. The initial viscosity (room temperature) of the prepared composition was 10.3 mPa·sec. The black resin composition for a light-shielding film was applied to alkali-free glass by spin coating to change the number of rotations, and the glass was dried at 90°C for 5 minutes, and then post-baked at 230°C for 30 minutes to make a glass substrate with light-shielding film .

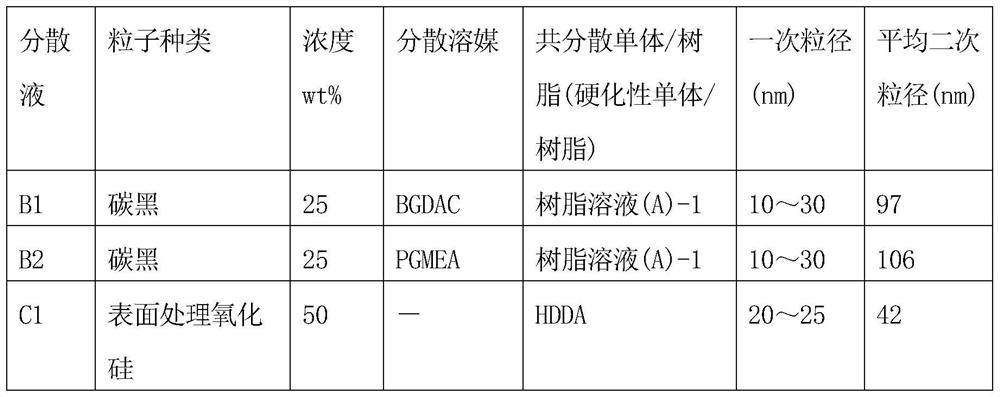

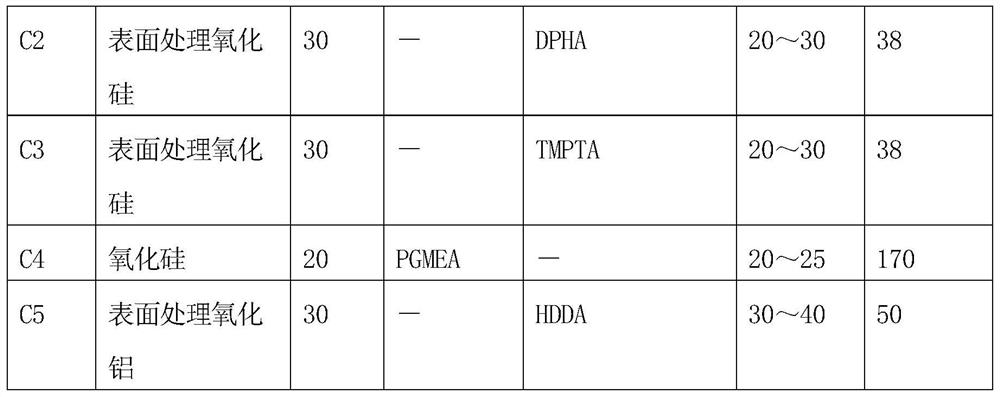

Embodiment 2 to 3、 comparative example 1 to 3

[0130] The aforementioned resin solution A2 and carbon black dispersion liquid B1 and the dispersion liquid containing transparent particles were mixed in parts by mass shown in Tables 2 to 3 to prepare a black resin composition for a light-shielding film, and the viscosity was measured in the same manner as in Example 1. Then, the black resin composition for a light-shielding film was coated on an alkali-free glass, dried at 90°C for 5 minutes, and then post-baked at 230°C for 30 minutes to form a glass substrate with a light-shielding film. The results are shown in Tables 2 to 3.

[0131] Compared with the glass substrate with a light-shielding film of Comparative Example 1 which does not contain transparent particles, the glass substrates with a light-shielding film of Examples 1 to 3 have the same carbon black concentration, which can reduce the reflectance. On the other hand, the glass substrate with a light-shielding film of Comparative Example 2 containing alumina particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com