Echo cancellation method for head-up display

A ghost elimination and head-up display technology, applied in the field of head-up display, can solve the problems of high cost, demanding wedge film angle, and high modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

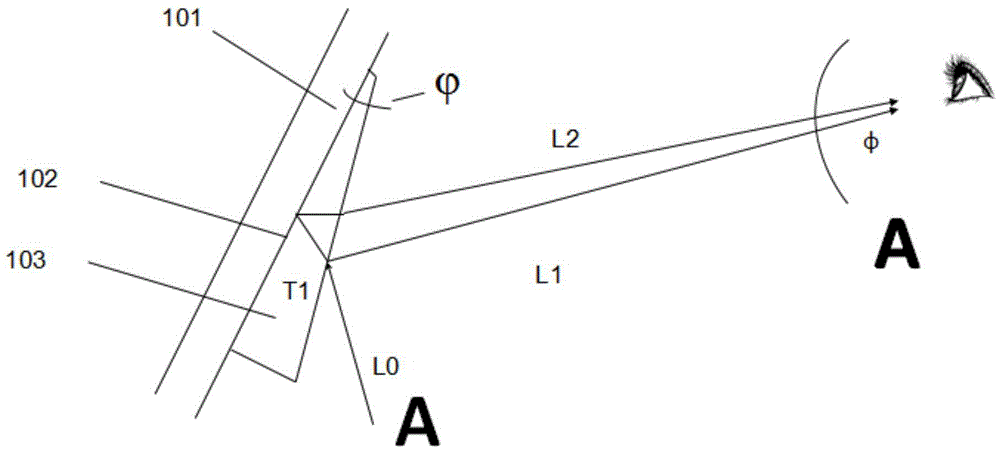

[0037] like figure 2 As shown, it is the structure and optical path schematic diagram of the automobile front windshield 101 and the ghost elimination plate 103 using the triangular light-transmitting plate in the method of the present invention, and the optical adhesive 102 is a silicone adhesive (Kraft K-5505H, Shenzhen, China). Zhiyantong Technology Co., Ltd.). The center thickness of the ghost removal plate 103 is 1.357 mm. The material of the ghost removal plate 103 is polyethylene terephthalate. The cross section of the ghost eliminating plate 103 along the thickness direction is triangular, that is, a triangular light-transmitting plate is used.

[0038] In general consumer models, the inclination of the front windshield is in the range of [40, 50], and the horizontal distance between the windshield and the driver is [0.75m, 0.9m]. Therefore, for the convenience of calculation, the inclination angle Φ of the automobile front windshield 101 is set as 45°, and the hor...

Embodiment 2

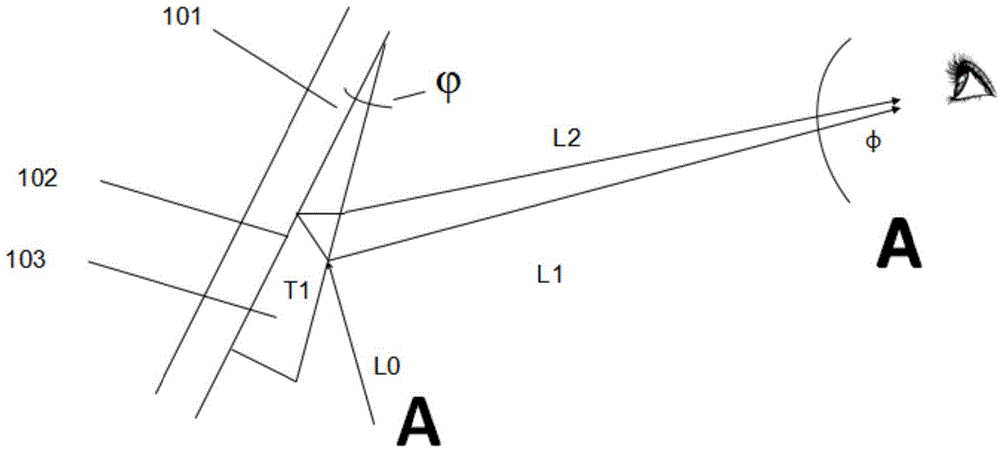

[0044] like image 3 As shown, it is a schematic diagram of the structure and optical path of an automobile front windshield 101 and a ghost-eliminating plate 103 using a wedge-shaped light-transmitting plate in the method of the present invention, and the optical adhesive 102 is a silicone adhesive (Kraft K-5505H, Shenzhen, China). Zhiyantong Technology Co., Ltd.). The center thickness of the ghost removal plate 103 is 0.607 mm. The material of the ghost removal plate 103 is polyethylene terephthalate. The cross section of the ghost eliminating plate 103 along its thickness direction is a trapezoid, that is, a trapezoidal light-transmitting plate is used.

[0045] In general consumer models, the inclination of the front windshield is in the range of [40, 50], and the horizontal distance between the windshield and the driver is [0.75m, 0.9m]. Therefore, for the convenience of calculation, the inclination angle Φ of the windshield 101 of the automobile is set to be 45°, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com