A mapping method from autoform stamping information to collision simulation model

A technology of stamping forming and simulation model, which is applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve stable mapping, enhanced accuracy, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

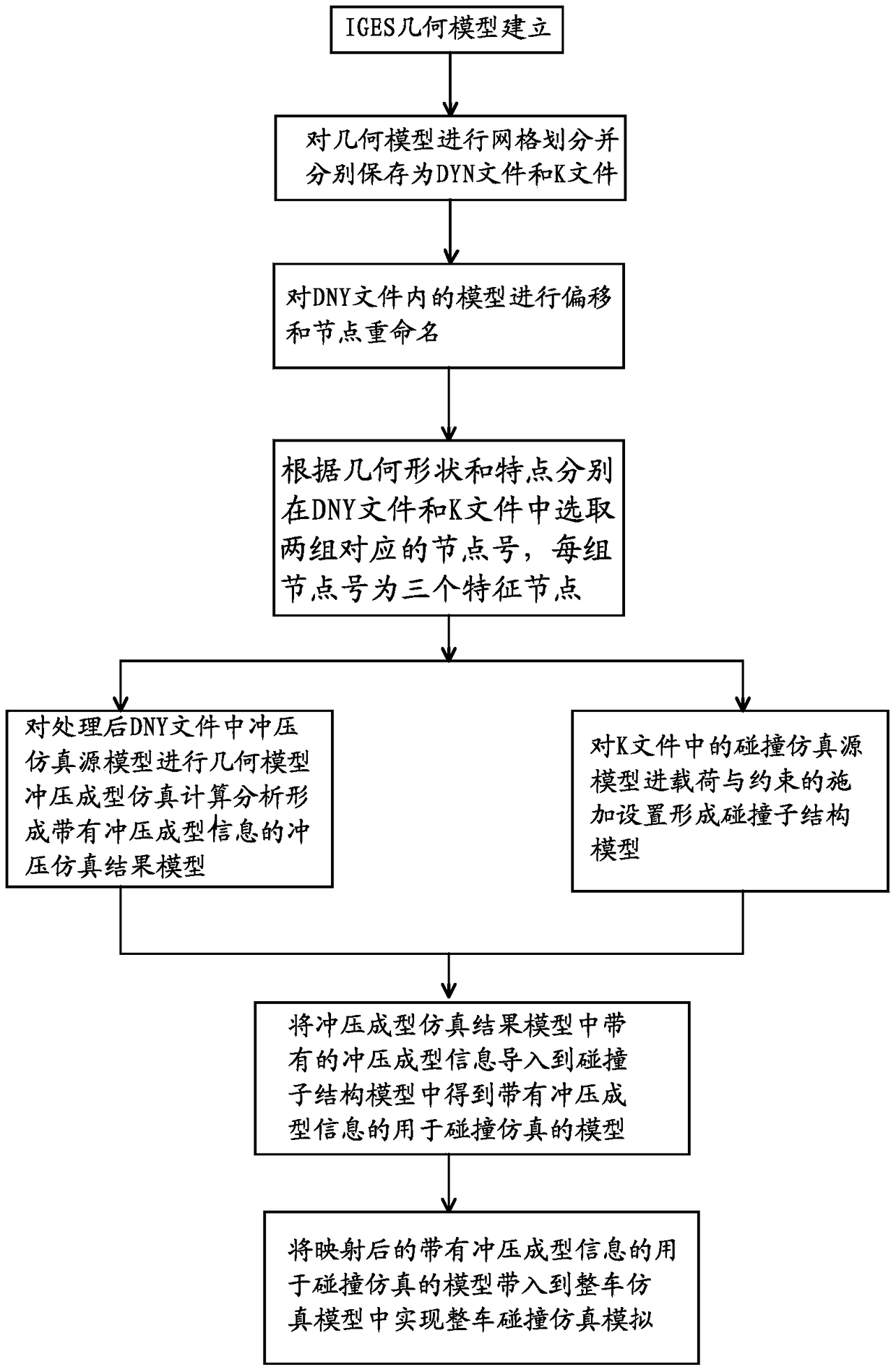

[0028] like Figure 1-2 As shown, the present invention is realized through the following technical solutions: the mapping method of Autoform stamping forming information to the collision simulation model comprises the steps:

[0029] A. Perform geometric grid division on the geometric model that needs to be mapped, and save the processed geometric model as a stamping simulation source model and a collision simulation source model with the same grid, and at the same time offset and node the stamping simulation source model Rename; so that the stamping simulation source model and the collision simulation source model are the same geometric model file with the same mesh division in different spatial orientations.

[0030]The stam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com