Rotation operation time difference signal trigger mechanism and isolating switch thereof

A technology of rotating operation and signal triggering, applied in the direction of air switch parts, etc., can solve the problems of personal safety and safety hazards, and achieve the effect of simple design structure, strong designability, and strong trigger time difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

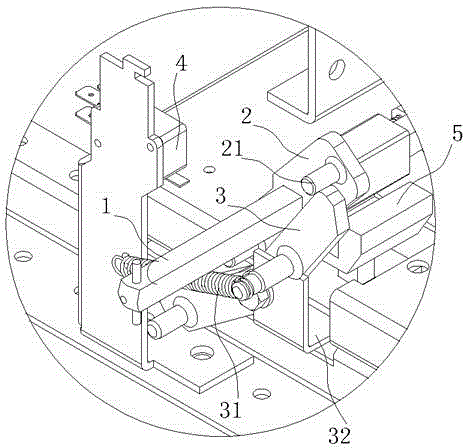

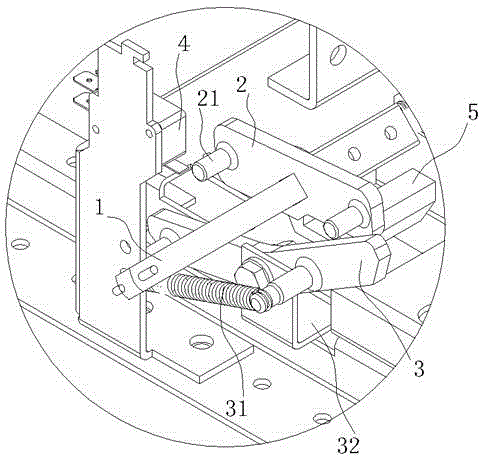

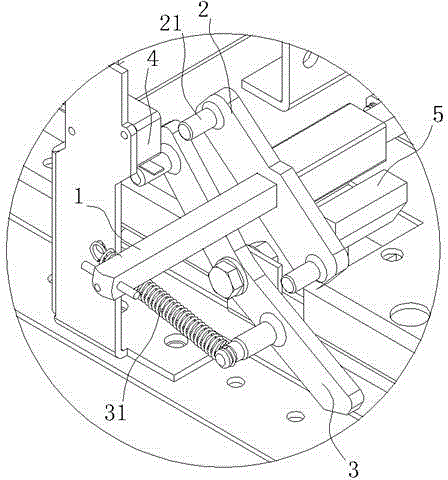

[0029] The rotary operation time difference signal trigger mechanism of the present invention includes a rotating shaft 1, a toggle member 2, a trigger member 3 and a trigger switch 4, the toggle member 2 is driven by the rotating shaft 1, and the trigger member 3 is within the rotation angle of the rotating shaft 1 It has a first stroke that can be driven by the toggle piece 2, and the trigger piece 3 also has a second stroke that can be triggered within the rotation angle of the rotating shaft 1. The trigger switch 4 is set on the first stroke or the second stroke of the trigger piece 3 Location. At the same time, there is a time difference between the first trip and the second trip. The rotating shaft 1 drives the toggle member 2, and the toggle member 2 drives the trigger member 3. The specific driving form may be a motion form including rotation or displacement. The design principle of the present invention is to use the time difference between the first stroke and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com