Material suction device for high-precision detection of chip

A suction device, high-precision technology, used in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of low degree of automation, high labor cost, manual confirmation, etc., to improve detection efficiency and automation Detection degree and detection efficiency, the effect of convenient individual detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

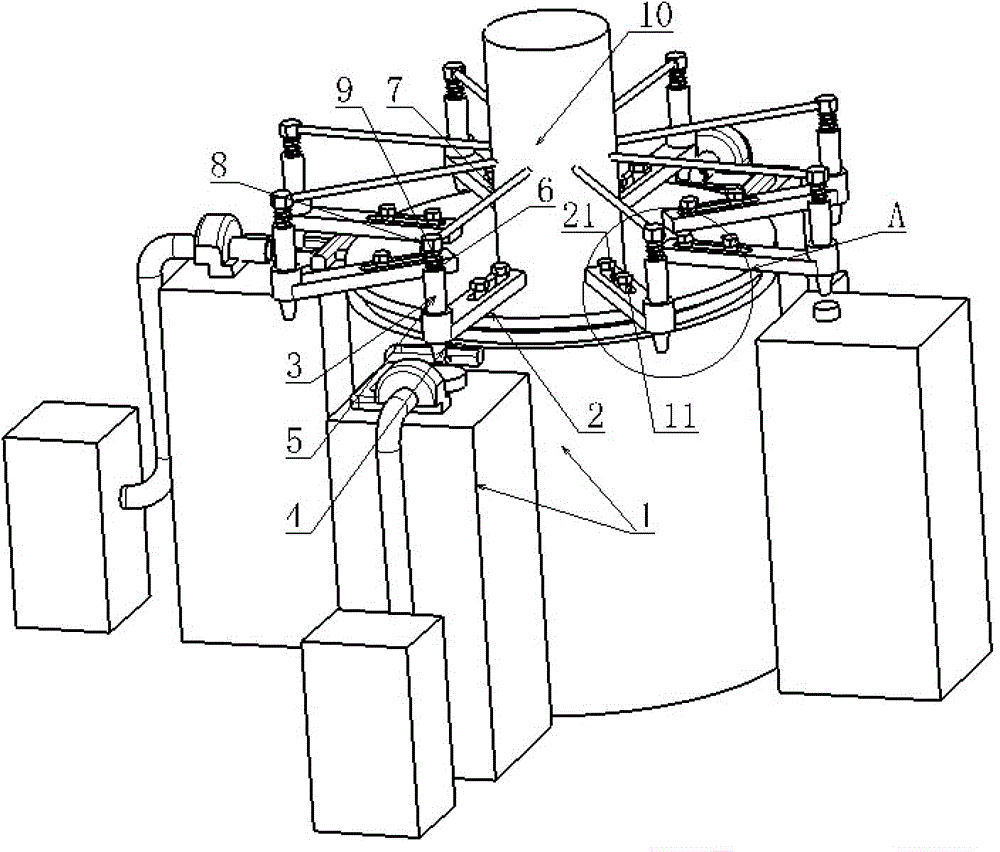

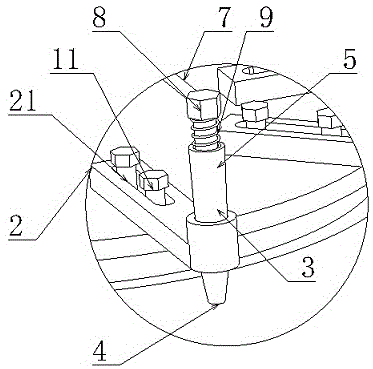

[0015] Such as figure 1 and figure 2 As shown, the suction device for high-precision detection of chips is connected directly above the detection platform 1 to realize a single automatic movement of the chip, including several support arms 2 connected above the detection platform 1, and each support arm The suction device 3 in 2; each suction device 3 includes a suction nozzle 4, a cylinder 5, a piston 6, and an air pipe 7 arranged from bottom to top. Right above, each support arm 2 is set on the outside of its corresponding cylinder 5 to fix it, the piston 6 slides up and down in the cylinder 5, one end of the air pipe 7 is connected to the piston 6, and the other end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com