Assistive device for detecting axial thermal deformation amount of vane wheel in automobile water pump

A thermal deformation and water pump technology, applied in the direction of mechanical solid deformation measurement, mechanical gap measurement, etc., can solve the problems of no relatively simple detection method and inability to effectively respond to axial deformation, etc., and achieve simple structure, low production cost, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

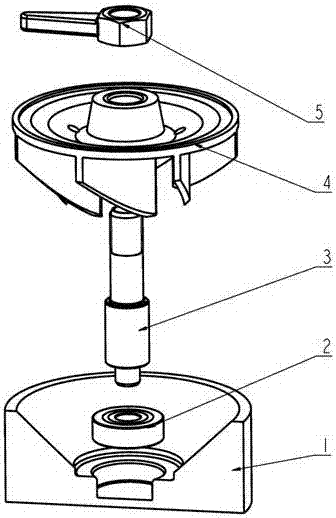

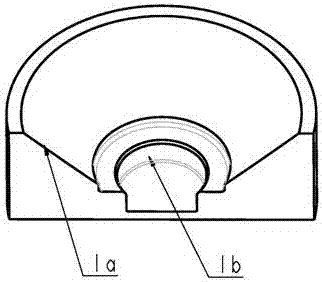

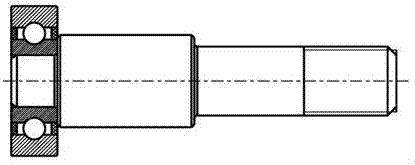

[0011] Such as figure 1 As shown, an auxiliary tool for detecting axial thermal deformation of an impeller in an automobile water pump is characterized in that: the auxiliary tool for detection is composed of a base 1, a rolling bearing 2, a stepped mandrel 3, an impeller 4, and a handle 5; figure 2 As shown, there is an inverted tapered detection groove 1a inside the base, and the contour shape of the conical surface of the detection groove 1a is consistent with the contour shape of the conical surface of the impeller 4 blades; the center of the bottom of the detection groove 1a is provided with a bearing hole 1b, and the rolling bearing 2 is assembled on In the bearing hole 1b; if image 3 As shown, the lower end of the mandrel 3 is in interference connection with the inner ring of the rolling bearing 2, the axis of the mandrel 3 coincides with the bearing of the detection groove 1a, the internal thread hole on the handle 5 meshes with the external thread on the upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com