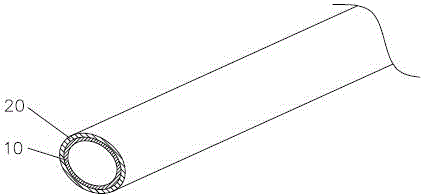

Heat-shrinkable composite stress pipe and production method thereof

A composite stress and stress tube technology, applied in applications, tubular items, other household appliances, etc., can solve the problems of cable breathing, poor product weather resistance, short product storage time, etc., and achieve good partial discharge and strong weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example 1

[0055] Heat-shrinkable composite stress tubes are produced by using the heat-shrinkable tube preparation materials and cold-shrinkable stress tube preparation materials of the following components according to the production method of the above-mentioned heat-shrinkable composite stress tube.

[0056] Heat-shrinkable stress tube preparation materials: 100 parts of EVA, 10 parts of modifier thermoplastic elastomer, 1.5 parts of antioxidant, 25 parts of barium titanate, 15 parts of conductive carbon black, 3 parts of lubricant stearic acid, and cross-linking auxiliary agent 3 0.8 parts of trimethylolpropane methacrylate, 4 parts of interface compatibilizer

[0057] Cold shrinkable stress tube preparation materials: 100 parts of EPDM, 2 parts of zinc oxide, 1.2 parts of stearic acid, 1.6 parts of antioxidant, 35 parts of carbon black SP5000 reinforcing agent, 50 parts of stress control agent barium titanate, 1 part of dicumyl peroxide as a vulcanizing agent,...

Example Embodiment

[0058] Example 2

[0059] Heat-shrinkable composite stress tubes are produced by using the heat-shrinkable tube preparation materials and cold-shrinkable stress tube preparation materials of the following components according to the production method of the above-mentioned heat-shrinkable composite stress tube.

[0060] Heat-shrinkable stress tube preparation materials: 50 parts of ethylene-vinyl acetate copolymer EVA, 50 parts of low-density polyethylene LDPE, 18 parts of modifier thermoplastic elastomer, 2.2 parts of antioxidant, 30 parts of barium titanate, 25 parts of conductive carbon black, 3.4 parts of lubricant zinc stearate, 1.4 parts of trimethylolpropane trimethacrylate, 6 parts of interfacial compatibilizer

[0061] Cold shrinkable stress tube preparation materials: 100 parts of EPDM, 5 parts of zinc oxide, 1.1 parts of stearic acid, 2.2 parts of antioxidant, 40 parts of carbon black N550 reinforcing agent, 34 parts of barium titanate, 38 parts of conductive carb...

Example Embodiment

[0062] Example 3

[0063] Heat-shrinkable composite stress tubes are produced by using the heat-shrinkable tube preparation materials and cold-shrinkable stress tube preparation materials of the following components according to the production method of the above-mentioned heat-shrinkable composite stress tube.

[0064] Heat-shrinkable stress tube preparation materials: 80 parts of ethylene-vinyl acetate copolymer EVA, 20 parts of low-density polyethylene LDPE, 25 parts of modifier thermoplastic elastomer, 1.8 parts of antioxidant, 10 parts of barium titanate, 35 parts of conductive carbon black, 30 parts of titanium dioxide, 3.8 parts of zinc stearate as a lubricant, 1.6 parts of divinyltoluene as a crosslinking aid, and 8 parts of an interfacial compatibilizer.

[0065] Cold shrink stress tube preparation materials: 100 parts of EPDM, 2 parts of zinc oxide, 1.2 parts of stearic acid, 2.8 parts of anti-aging agent, 60 parts of too good N660 reinforcing agent, 18 parts of ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com