Thermostat

A thermostat and burner technology, applied in the field of thermostats, can solve problems such as component wear and gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

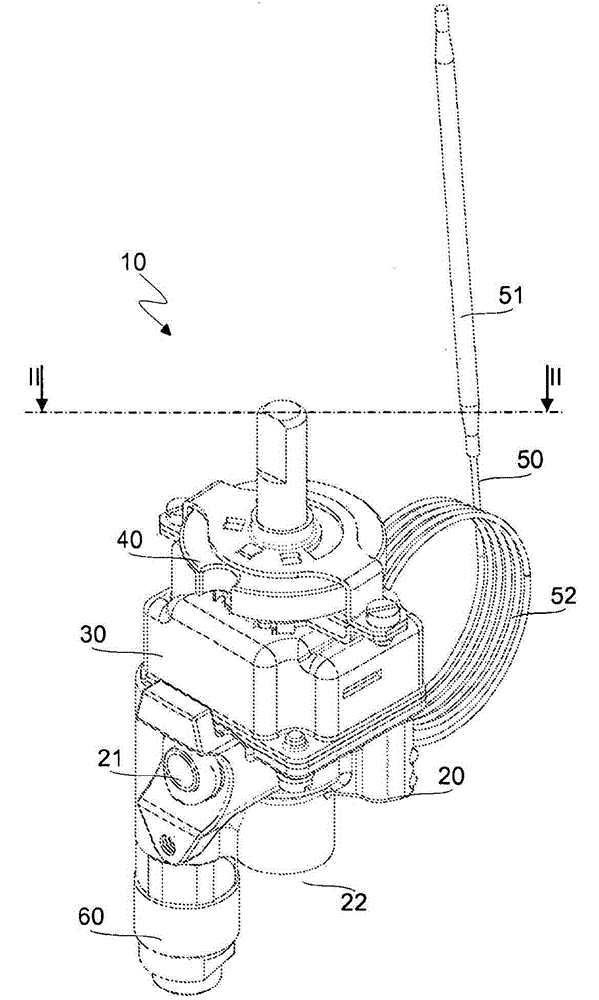

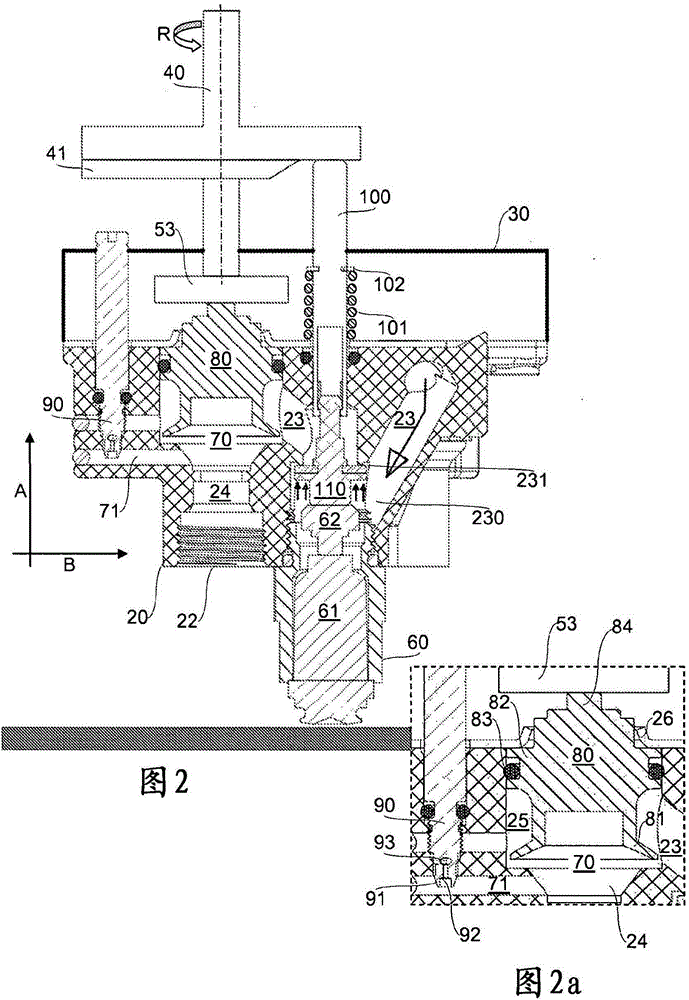

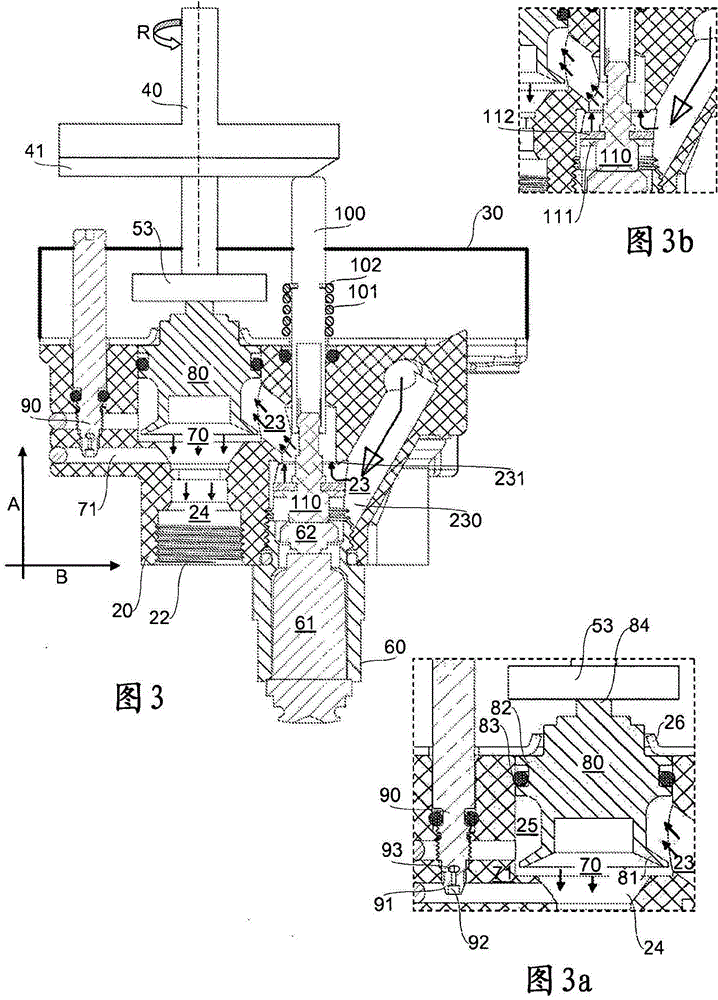

[0027] refer to figure 1 , The thermostat 10 according to the invention comprises a body 20 inside which are formed a plurality of ducts suitable for supplying a gas flow from an inlet opening 21 to an outlet opening 22 to a burner (not shown). The inlet opening is for connection to a gas source and the outlet opening is for connection to the burner through a suitable conduit.

[0028] The thermostat 10 also includes a bell 30 secured to the body 20, for example by screws, which rotatably supports a coupling member 40 configured to allow the installation of knobs (not shown) for ignition and temperature adjustment of the burner. out).

[0029] The thermostat 10 further comprises a thermostatic package 50 equipped with a probe 51 for insertion in a compartment to be heated, for example a compartment of an oven. A conduit 52 filled with a heat-expandable fluid medium (eg diathermy oil) is connected to the probe 51 of the thermostat 50 . The thermostatic pack 50 also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com