Method for producing a three-dimensional characteristic model of a porous material sample for analysis of permeability characteristics

A technology of porous materials and three-dimensional features, which is used in the research field of porous materials and media properties to achieve the effect of improving accuracy, accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

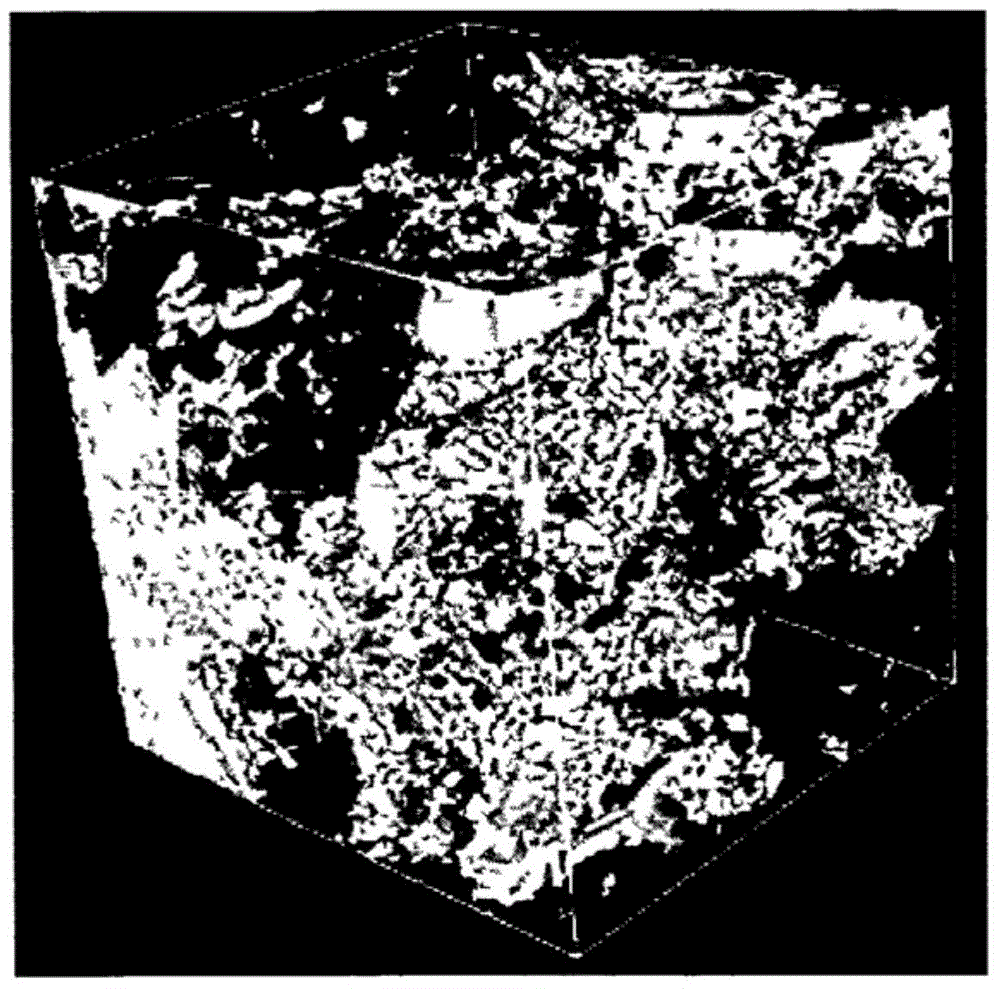

[0035] In the description of the present invention, as an example, the claimed technique is applied to a cylindrical core sample. This clearly cannot be considered as limiting the possible application of the claimed method in any other design and form of porous media, including drill cuttings.

[0036] First, the core is raised to the surface through the spud process and transported to the laboratory, where it is typically sliced into smaller-sized samples for microtomography studies.

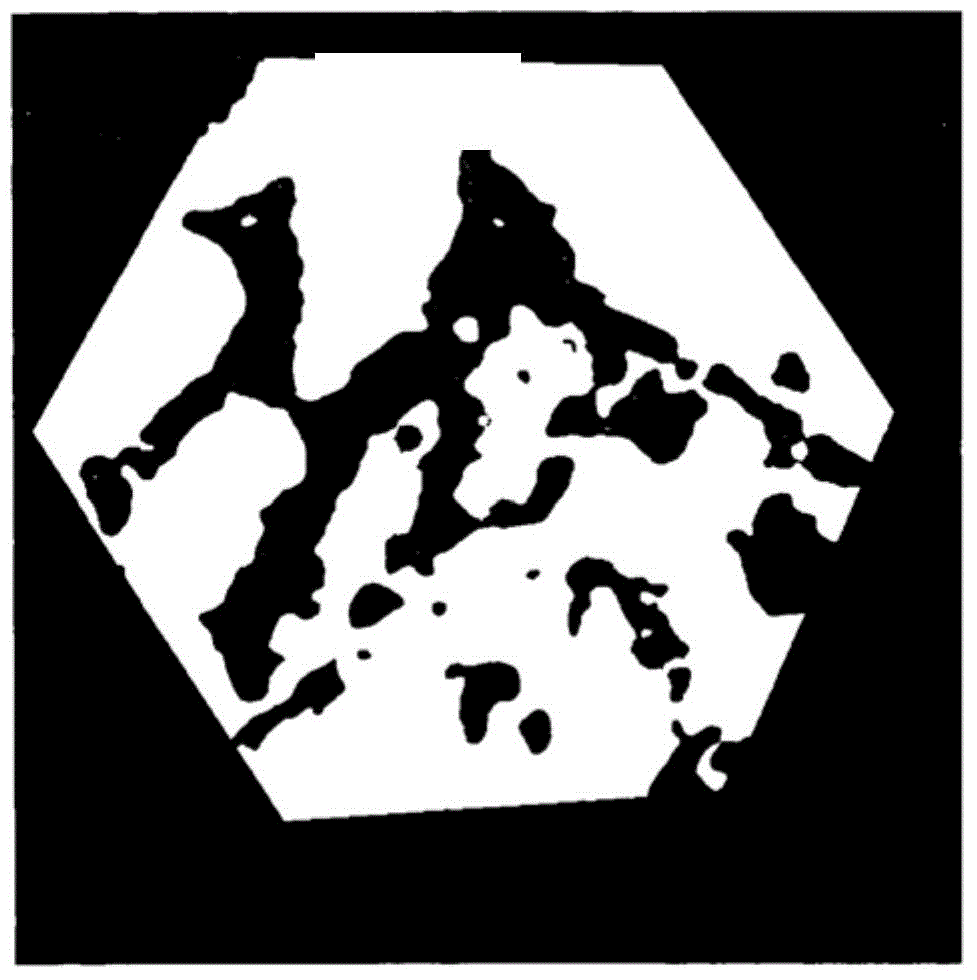

[0037] Furthermore, the tomographic study of the sample is performed with sufficient resolution (necessary pixel size of the tomographic image). The result is a set of successive images of the core, each represented by pixels of a different gray scale (from pure white to pure black). Here white corresponds to the highest bulk density and black corresponds to the lowest bulk density.

[0038] The next step is to distinguish areas of uniform density in the material sample. This step can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com