a silage machine

A technology of silage machine and rack, applied in the field of silage machine, can solve the problems of single function of agricultural machinery, very broken corn stalk powder, labor-intensive and time-consuming, etc., to save time and labor, reduce maintenance costs, and large maintenance space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The silage machine of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

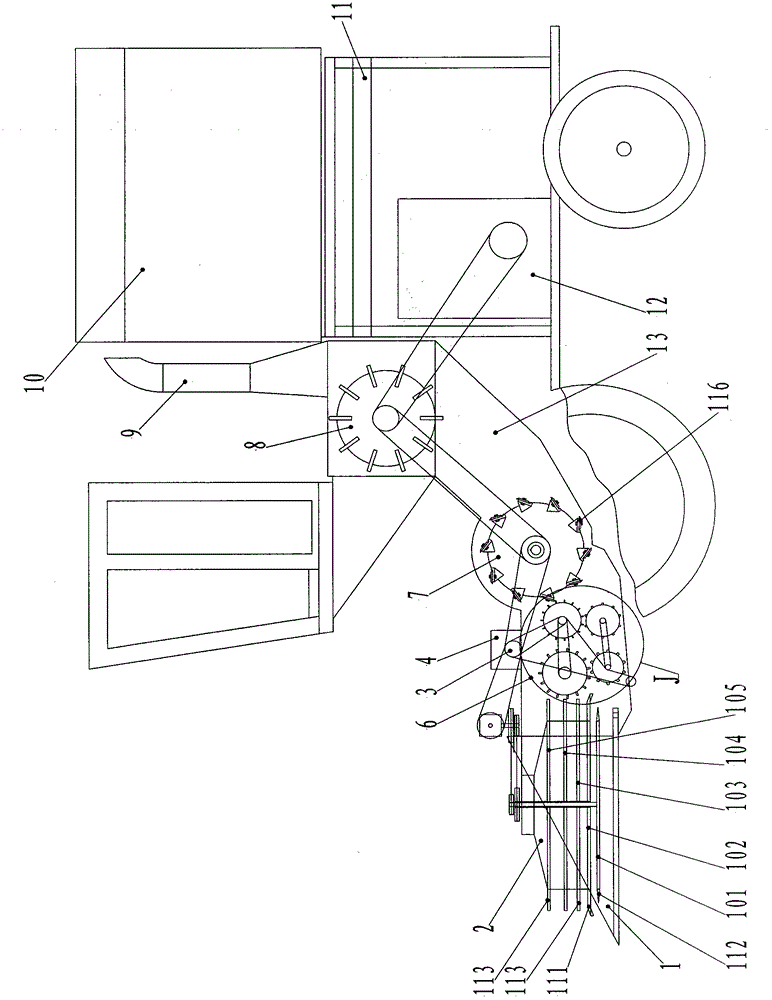

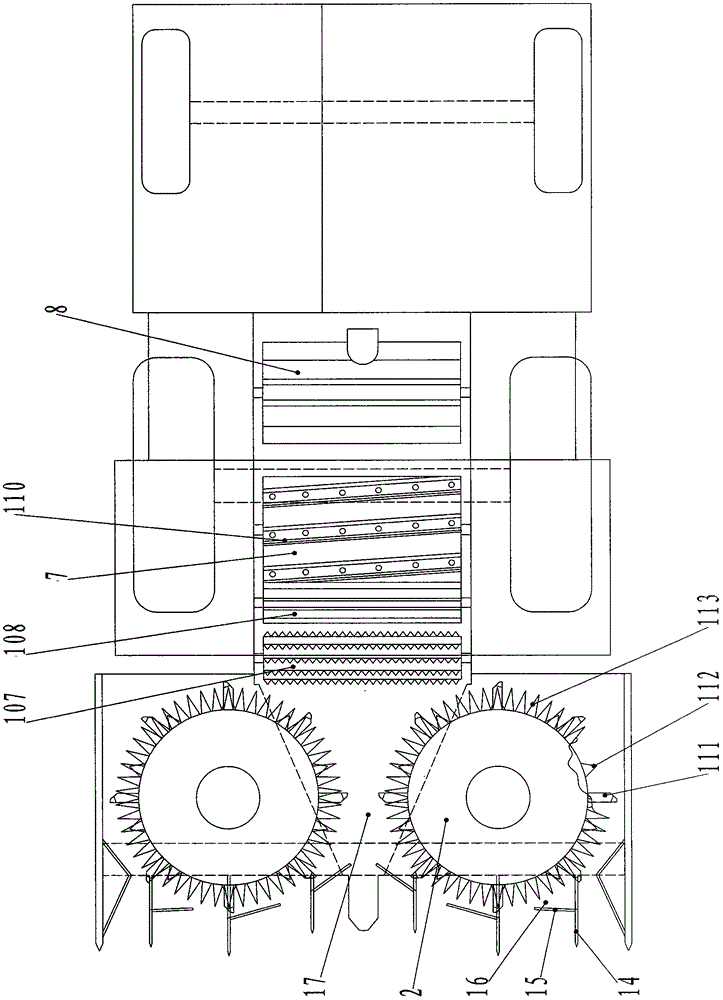

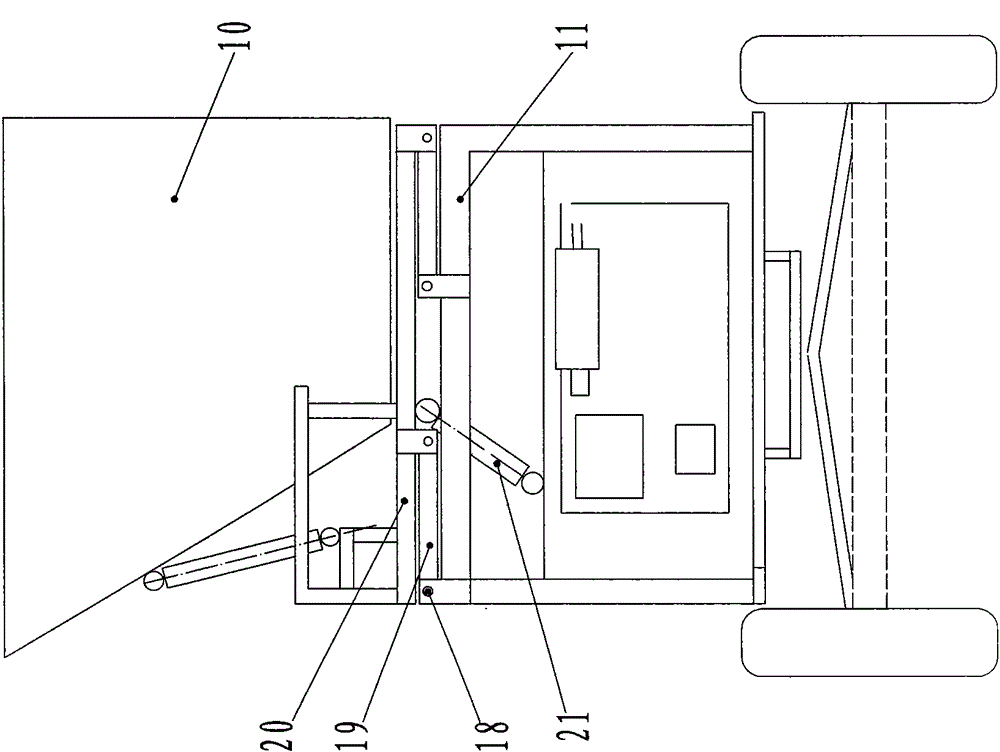

[0025] figure 1 It is a structural schematic diagram of a silage machine of the present invention, figure 2 yes figure 1 top view of Figure 4 yes figure 1 Zoomed-in view at middle J, Figure 5 yes Figure 4 The top view of middle part 106 and part 109, in the figure, this silage machine, comprises frame 11, is arranged on the feed bin 10 on frame 11 and the header 1 of frame 11 front ends, and frame 11 is provided with engine 12, The rear end of the header 1 is connected to the feeding box 13, and the upper end of the feeding box 13 is provided with a discharge cylinder 9. On the header 1, two cutter dials 2 with opposite directions of rotation are arranged side by side, and two cutter dials 2 The axis of rotation is vertically arranged, and the cutter dial 2 is provided with a multi-layer dial, and the following o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com