K6 side frame groove processing miller apparatus

A side frame and milling machine technology, which is applied in the field of milling machine devices for side frame groove processing, can solve the problems that the chamfering process cannot be completely machined, low production efficiency, low processing accuracy, etc., and achieves simple structure, high production efficiency, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

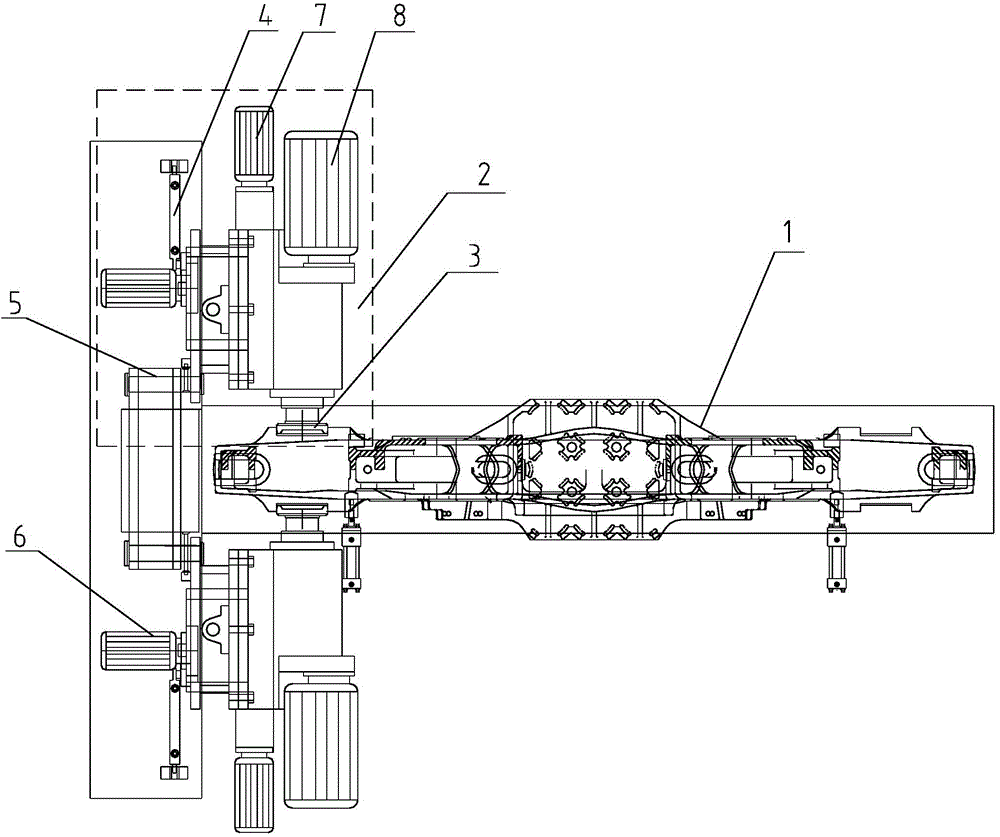

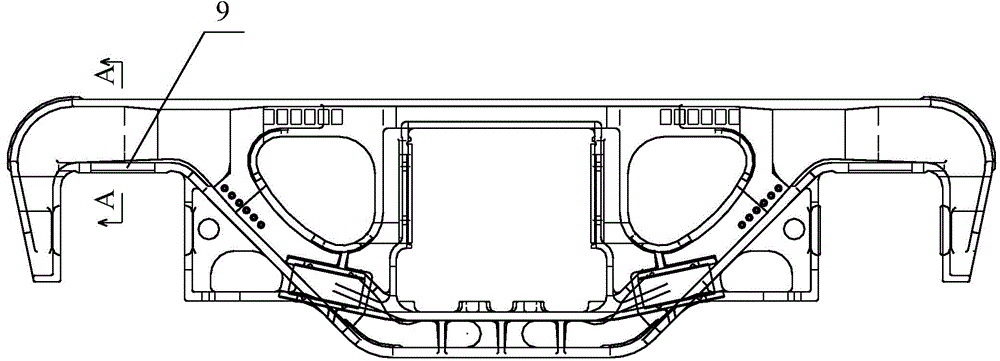

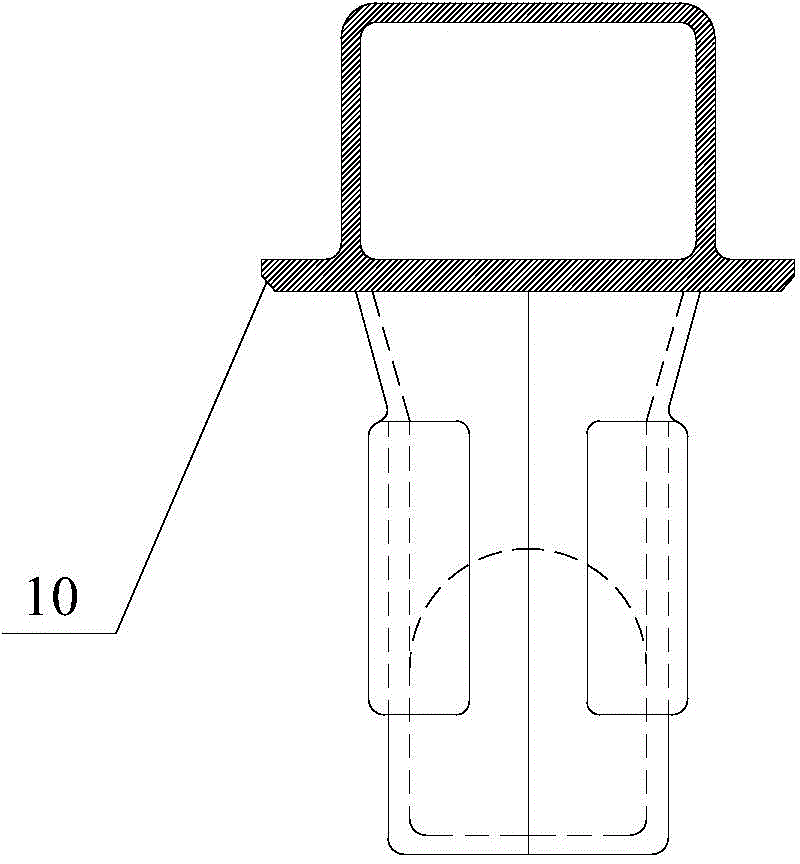

[0023] to combine figure 1 , figure 2 , image 3 , a milling machine device for side frame groove processing, including a base, the base includes a workpiece mounting base and a power head mounting base, wherein the workpiece mounting base is used to install the side frame 1, and the power head mounting base is provided with two power heads 2. The power head 2 includes a milling head 3. The milling head 3 mills grooves on the side frame 1 to obtain a groove 9. Two power heads 2 are symmetrically distributed on both sides of the side frame 1. Each power head 2 is connected to a The rotary cylinder 4 drives the power head 2 to rotate, so that the milling head 3 chamfers the groove 9 to obtain a chamfer 10 . The structure of the base, the workpiece mounting base, and the power head mounting base is not shown in the accompanying drawings.

[0024] Wherein, the power head 2 includes a milling head 3 and a servo motor 8, the servo motor 8 is used to drive the milling head 3, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com