Annular rolling precise welding device

A precision welding and annular technology, applied in the direction of roller electrode welding, auxiliary devices, welding equipment, etc., can solve the problems of reduced sealing performance, high labor intensity, low production efficiency, etc., and achieve the effect of improved sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

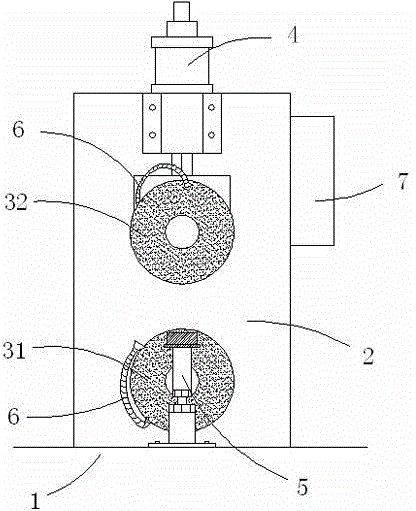

[0017] An annular rolling precision welding device has a horizontal workbench 1 and includes a rolling resistance welding structure. The rolling resistance welding structure includes a lower welding wheel 31 located below and an upper welding wheel 32 vertically above the lower welding wheel 31. The lower welding wheel 31 is a fixed installation, the top of the last welding wheel 32 is against the cylinder 4, the upper welding wheel 32 is driven by the cylinder 4 to move up and down, the diameter of the upper welding wheel 32 is equal to that of the lower welding wheel 31; the front of the lower welding wheel 31 is fixedly installed There is a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com