Improved vertical lathe centering clamp

A technology of centering fixtures and vertical lathes, which is applied in the direction of clamping, positioning devices, clamping devices, etc., can solve the problems of large loss of spare parts, difficulty in machine tool crashes, short maintenance cycles, etc., and achieve simple centering structure and stable fixture accuracy , easy recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

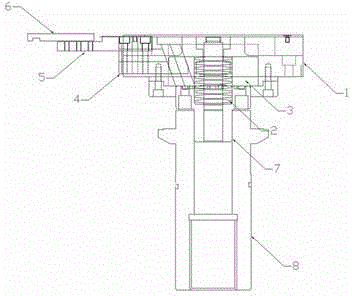

[0008] Improved centering fixture for vertical lathe, including power chuck main body 1, center disc spring 2, compression head 3, telescopic claw 4, small chuck pulling claw 5, small chuck pulling plate 6, telescopic head 7, machine tool pull rod head 8. The main body of the power chuck 1 is fixed to the base of the machine tool fixture by bolts, the telescopic head 7 is connected with the pull rod of the machine tool cylinder, the telescopic claw 4 is connected with the small chuck pulling claw 5, and the small chuck pulling claw 5 is connected with the small chuck pulling plate 6, The small chuck pulling plate 6 is connected with the radial slide seat of the fixture, the compression head 3 is connected with the telescopic head 7, and the center disc spring 2 is installed in the telescopic head. When clamping is loosened, the pull rod of the oil cylinder moves upwards and downwards, pushing the compression head 3 and the telescopic head 7 to move up and down, and drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com