Pendulum compression type mobile garbage compression equipment

A garbage compression and compression technology, which is applied to presses, manufacturing tools, etc., can solve the problems of reduced service life of compression devices, low utilization rate of box volume, waste of space resources, etc., to improve compression ratio, improve maintenance efficiency, The effect of avoiding garbage congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

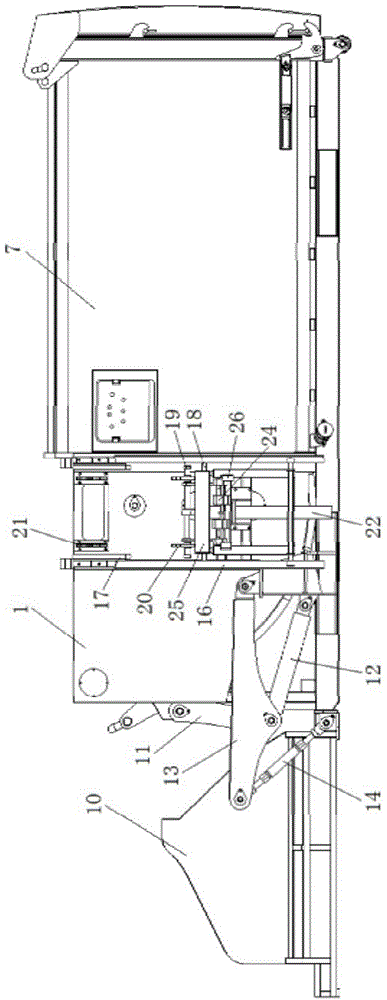

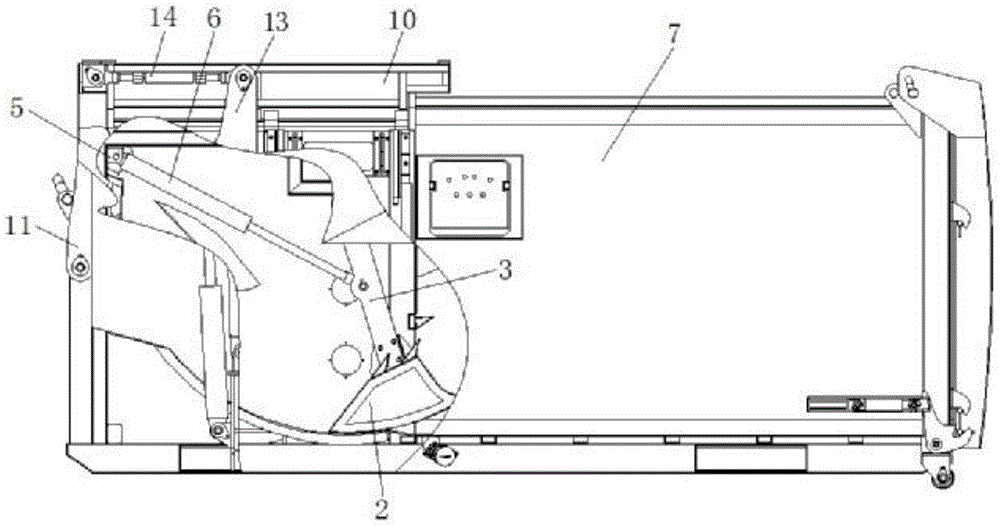

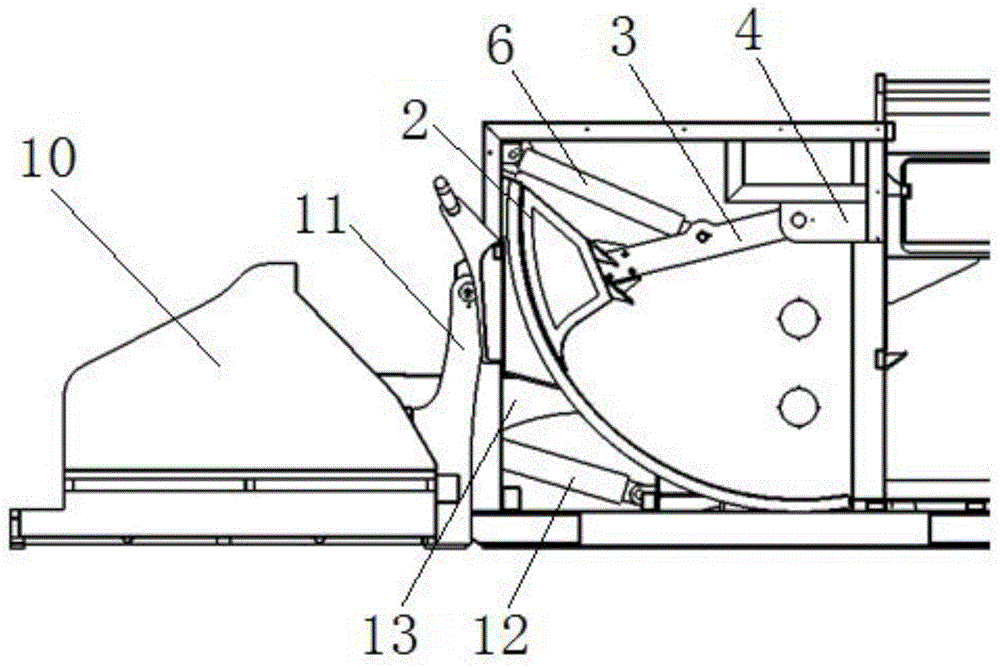

[0027] Such as Figure 1 to Figure 3 As shown, a pendulum compression type mobile garbage compression equipment includes a feeding mechanism, a compression mechanism and a garbage recovery chamber 7. The feeding mechanism is used to collect garbage, and the collected garbage is uniformly sent to the compression mechanism through the feeding mechanism for further processing. Compression, the compression mechanism includes a compression chamber 1, the opening of the top surface of the compression chamber 1 is the feed inlet of the compression mechanism, and the feed mechanism sends the garbage into the compression chamber 1 through the feed inlet of the compression mechanism, and the compression chamber 1 There is a compression push head assembly inside, and the compression push head assembly includes a push head body 2 and a connecting rod 3, wherein the push head body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com